It’s a rite of spring for the U.S. nuclear power industry. Plant operators schedule refueling outages, taking a reactor offline not only to refuel but also to perform repairs or other maintenance, and facility upgrades. It’s a task made more problematic this year, as social distancing and travel restrictions brought on by the COVID-19 pandemic mean plant managers are performing a juggling act to accomplish refueling work on a timely basis.

U.S. nuclear plants typically schedule these outages during the spring and fall, when power demand is lower. Nuclear reactors usually refuel every 18 to 24 months. According to the U.S. Energy Information Administration (EIA), refueling outage times have lessened in recent years, dropping from an average of 46 days in 2012 to 32 days in 2019, with some reactors requiring refueling durations of fewer than 20 days last year.

This year’s refueling outages, though, may not be typical, due to staffing issues caused by the coronavirus. POWER recently reported that according to EIA, 56 of the nation’s 58 operating nuclear reactor sites have scheduled outages this year, and measures taken to keep staff safe during the pandemic could impact how the work gets done.

Those possible coronavirus impacts to critical operations for the U.S. power industry are why the Nuclear Energy Institute called on the federal government to designate nuclear power plant workers as essential, and to take steps to support those workers so plants could continue refueling outages unabated. Other federal energy agencies have called for workers at all the nation’s power plants to be considered essential to the nation’s pandemic response.

Additional Personnel Needed

Refueling operations usually require nuclear plants to bring in additional workers to supplement existing staff. Exelon Generation, which conducted refueling outages at some of its reactors earlier this year, told POWER that more than 1,200 extra workers joined 800 Exelon employees during the outage at Byron 1 in Illinois; 1,300 additional staff participated in work at Nine Mile 1 in New York.

Additional contract workers also are on-site at the nation’s largest power plant of any kind, the Palo Verde Generating Station near Tonopah, Arizona. Palo Verde has three operating pressurized water reactors, and the plant has a total power generation capacity of more than 4,000 MW. Palo Verde sits on about 4,000 acres in Maricopa County, and supplies power to areas of Arizona and Southern California, as well as New Mexico and west Texas.

The plant began a refueling outage on its Unit 2 at 12:01 a.m. Mountain time on April 4. Greg Cameron, director of Nuclear Communications for Arizona Public Service (APS), told POWER the fuel to replenish the reactor “arrived around the first of the year. Our units are refueled every 18 months.” The plant schedules its outages to occur in April and October, leaving at least six months in between outages for each individual reactor. Unit 2 will next be refueled in the fall of 2021.

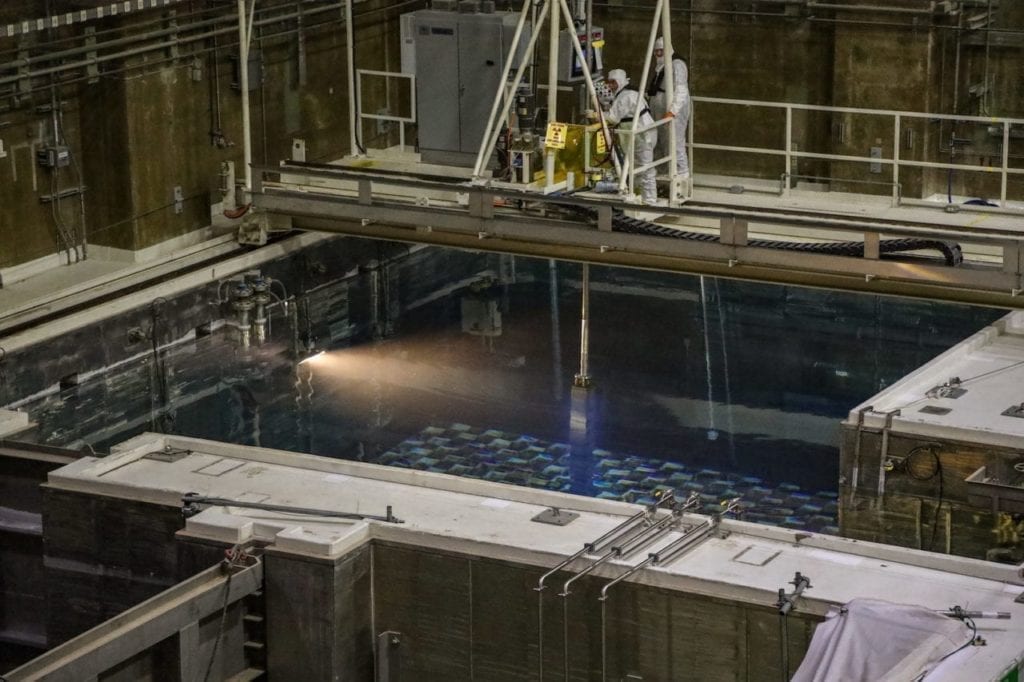

Palo Verde’s three nuclear reactors operate independently; taking one offline for refueling does not impact the other two. About one-third of the fuel in a reactor core is changed out for fresh fuel during the outage period (Figure 1).

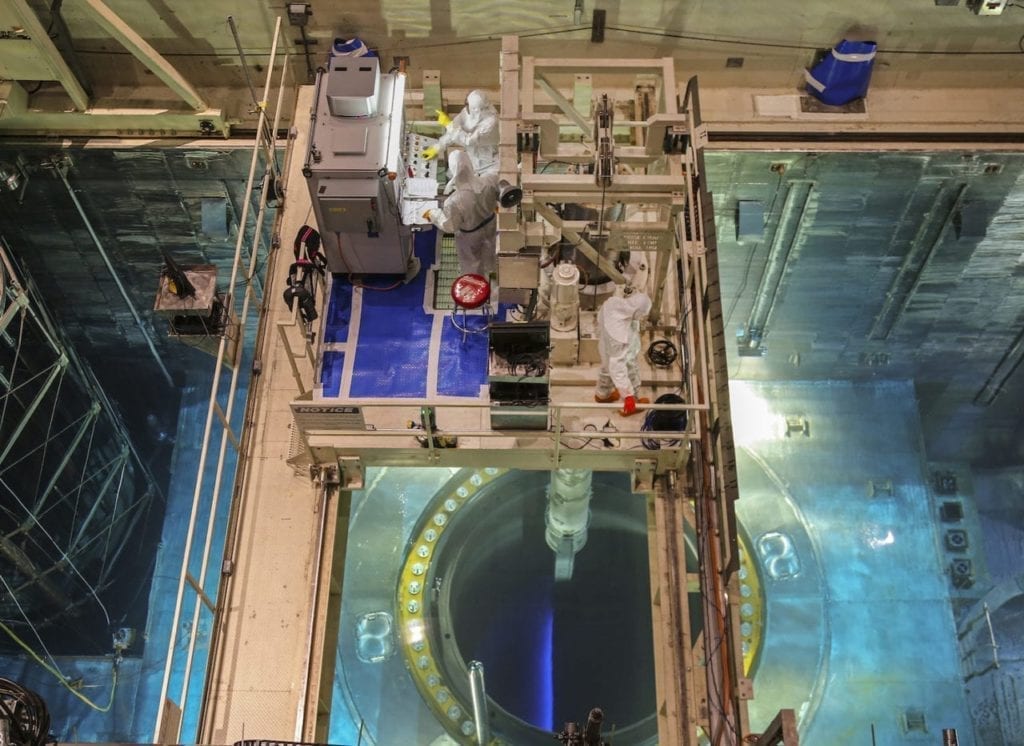

The oldest uranium rods in the reactor are moved to a holding pool, and cooled there for several years before eventually being place in dry storage casks. Energy produced by a uranium rod lessens over time, and fuel remaining in the reactor is arranged to evenly distribute its heat before new fuel rods are added. The process involves a machine, basically a crane-like device with a claw, that ensures rods never leave the water in the containment vessel. The vessel shields radiation and prevents the nuclear fuel from overheating (Figure 2).

“We have about 2,000 full-time employees at Palo Verde,” Cameron said. “For a typical refueling outage, we bring in [an additional] 800 to 1,000 contractors. They do various jobs and have different skills. Some are radiation protection technicians, some are specialized welders, some do other specialized jobs. Typically, not all of them are on-site on the same day.”

Outage Will Last ‘About a Month’

Jill Hanks, a spokesperson for APS, told POWER “a typical outage is about a month” at Palo Verde. APS operates the plant, which is owned by several groups, including APS, Salt River Project, El Paso Electric, Southern California Edison, PNM Resources, Southern California Public Power Authority, and the Los Angeles Department of Water and Power.

Cameron and Hanks noted that many of the 2,000 full-time staff at Palo Verde are now working remotely. “We’ve asked that folks who can do their jobs at home, to do them there,” Cameron said. “For this outage given the circumstances, we’ve reduced by about 50% the number of full-time [workers on-site] and 40% of the contractors. That’s in terms of number of people. We’ve decreased the amount of time they’re on-site, and we might bring them on a few days early for training. Contractors are taking their training remotely at their hotel. We’re trying to make sure we have the fewest number of people on-site as possible, and that they’re only there when they need to be.”

The two emphasized that the plant has “narrowed the outage scope in order to have the least amount of people and for the least amount of time while still safely and reliably completing essential outage work.”

Hanks and Cameron said the pandemic has meant new protocols for conducting business at the plant. Palo Verde’s regular public tours are on hold indefinitely, and workers on-site follow a scripted plan to limit group interaction. In a filing to the Arizona Corporation Commission, which oversees business operations in the state, the plant said in part: “At the Palo Verde Generating Station, employees are revising the outage scope for the upcoming Unit 2 routine refueling and maintenance outage. With this revision, only work that is absolutely required [Figure 3] for refueling the unit to safely and reliably operate for the next 18 months will be conducted, which includes the summers of 2020 and 2021. Work requiring the employment of a significant number of temporary contractors has been removed from the outage scope, and deferring that work will not compromise reliability.”

Social Distancing

“We have the same social distancing practices as recommended for the general public,” Cameron said, though he noted the plant has expanded upon that, going above and beyond—like “social distancing on steroids,” he said.

“We’ve split up some of the groups on-site,” to ensure meetings occur among small groups of maybe 10 or fewer people. “If we have 20 people in a meeting, we may have them in a [large] tent outside,” he said.

Cameron said the plant “has separate travel paths, separate entry points” for on-site workers. “We’re trying to implement as much distance [between people] as possible while keeping the lights on.”

Cameron said the refueling outage provides an “opportunity to do other maintenance [and] equipment upgrades. Some of that work is ‘good to do versus have to do.’ We looked at that, and we can defer some of that. Everything that is either regulatory required, or necessary for reliability, we will do.

“We didn’t take anything out of the outage that would impact reliability,” Cameron said, noting the “have to do” part of the outage schedule has not changed. “Any work we defer has no impact on safety or reliability. We haven’t compromised anything for safety or reliability’s sake.”

Hanks and Cameron said the team at Palo Verde, like those at other plants, recognize the importance of their jobs during one of the most uncertain periods in U.S. history. Keeping the lights on at hospitals and other medical facilities, and to help limit the coronavirus’ already significant damage to the nation’s economy, is critical.

Said Cameron: “Reliable electricity matters now more than ever.”

—Darrell Proctor is associate editor for POWER (@DarrellProctor1, @POWERmagazine).