The Nakoso integrated coal gasification combined cycle (IGCC) plant, a much-watched power project in Japan’s Fukushima prefecture because it incorporates a pioneering advanced coal gasification technology, began commercial operations on April 16, following its handover to owner Nakoso IGCC Power GK by a Mitsubishi Power–led consortium.

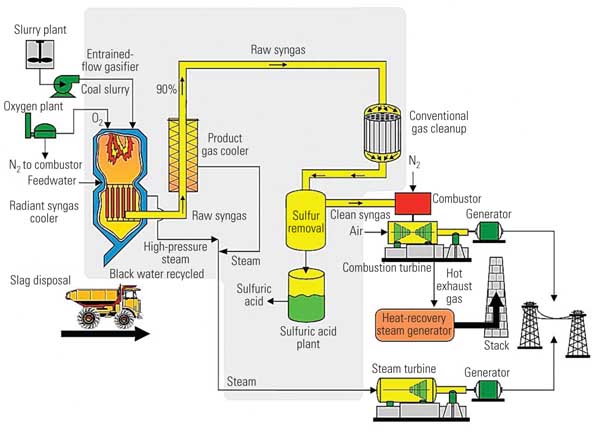

As with all IGCC power plants, the 543-MW Nakoso IGCC facility (Figure 1) combines coal gasification in a furnace—to derive syngas, a mixture of primarily hydrogen and carbon monoxide—and gas and steam turbines to generate power. But at the Nakoso IGCC facility, the gasifier uses air-blown technology, essentially relying on a reaction between coal and air to generate the combustible syngas.

|

|

1. The 543-MW Nakoso integrated coal gasification combined cycle (IGCC) facility in Fukushima prefecture began operations on April 16, 2021. Courtesy: Mitsubishi Power |

According to Mitsubishi Power, which manufactured the air-blown IGCC system, the gasifier is based on a two-stage entrained bed, which has a combustor in the lower chamber and a reductor in the upper chamber (Figure 2). “In the combustor, coal and char are burned, and high-temperature gas is generated,” it explained. “In the reductor, the coal is gasified in the high-temperature gas. Securing the syngas calories necessary for gas turbine combustion, the gasifier melts ash and discharges it smoothly during [the] combustion stage,” thereby achieving two roles at the same time, it said.

|

|

2. The gasifier in the air-blown IGCC design has a two-chamber two-stage structure, consisting of a combustor in the lower (first) stage and a reductor in the upper (second) stage. Courtesy: Mitsubishi Power |

Four Decades of Development

Mitsubishi Power’s technology derives from nearly four decades of development, operation, and validation, said the company, which is a subsidiary of Japanese technology giant Mitsubishi Heavy Industries. In 2013, Mitsubishi Power wrapped up a successful demonstration of the air-blown technology at the 250-MW IGCC unit at Joban Joint Power Co.’s Nakaso Power Plant Unit 10 nearby in Iwaki, Fukushima, and declared it commercially operable. The Nakoso Unit 10 plant “set a record for 3,917 hours of continuous operation,” Mitsubishi Power reported at the time.

In September 2014, the company and partners Mitsubishi Heavy Industries Engineering Ltd., Mitsubishi Electric Corp., and Mitsubishi Power Environmental Solutions bagged a major order from Tokyo Electric Power Co. (TEPCO) for two 500-MW-class IGCC plants at Joban Joint Power’s Nakoso plant as well as at TEPCO’s own Hirono Power Station in Futaba-gun. The projects, TEPCO said, would help Fukushima prefecture to promote local industrial recovery following the 2011 earthquake, tsunami, and nuclear plant disaster.

Mitsubishi Power said in April that compared to the smaller Nakoso Unit 10, Nakoso IGCC’s efficiency has been “substantially enhanced” to reach 48% net thermal efficiency on a lower heating value (LHV) basis. One reason is that the plant adopts a configuration—similar to that at the Hirono plant—in which “the gas turbine is combined with a steam turbine that operates using the steam generated by a waste heat recovery boiler fueled by waste gas,” the company noted.

For Mitsubishi Power, commercial start at the Nakoso IGCC plant marks a new pathway to achieve “effective use of resources, environmental conservation, and improve decarbonization.” It said, for example, that its advanced IGCC system is 10% to 15% more efficient than a 600C–class ultrasupercritical (USC) coal-fired unit.

Those efficiency gains translate into carbon cuts. “While the global average for CO2 emissions from coal-fired power plants is 950g CO2 /kWh at generator terminal, with the IGCC we are targeting emissions of 650g CO2 /kWh at generator terminal,” it said. Catering to growing fuel flexibility needs, the gasification process is also more accommodating of various coal types, especially those with low-melting-point ash, than pulverized coal boilers.

Interest in IGCC Has Waxed and Waned

Nakoso IGCC (and the Hirono unit, when it comes online as slated at the end of this year) join only a handful of commercial-sized IGCC coal-fired power plants that are operational around the world. Along with the Nakoso IGCC unit and Nakoso Unit 10, Duke Energy continues to operate the 2013-built 618-MW Edwardsport IGCC Station in Indiana. Also reportedly still operating are the 400-MW Vresová project in the Czech Republic, and Korea Western Power Co.’s 300-MW Taean pilot plant.

Owing to cost pressures and uncertainty around carbon emissions policy, several iconic IGCC plants have closed over the past decade. These include the 300-MW Puertollano unit in Spain and the 250-MW unit in Buggenum in the Netherlands. On June 1, Tampa Electric told POWER its 1996-completed 250-MW Unit 1 at the Polk Power Station in Florida is not currently operating, but “it has not been retired,” a spokesperson said. “It remains part of our long-term plans.” Plans to close the 1995-completed 265-MW Wabash IGCC in Indiana, meanwhile, appear to have been reversed to convert the plant’s gasifer to hydrogen firing with carbon capture and storage and converting its gas turbine to hydrogen-firing, a DOE official told POWER in late May.

As Toby Lockwood, a senior analyst and event lead for the International Energy Agency Clean Coal Centre (IEA CCC), pointed out in a February 2021 report, interest in IGCC technology has waxed and waned, driven mainly by policy and economics. While a number of demonstration IGCC plants were deployed in the 1990s and early 2000s in the U.S., Europe, and Japan, IGCC plants failed to gain popularity owing to “unexpectedly high costs for several of these units, complexity of operation, and the concurrent improvement in pulverized coal plant efficiency,”

Interest was renewed in the late 2000s due to its potential application in pre-combustion capture of carbon dioxide, but several pre-combustion demonstration projects—among them, the U.S. Department of Energy’s (DOE’s) FutureGen, Australia’s Zerogen, and Southern Co.’s Kemper County IGCC project—were ultimately scrapped or repurposed. In China, the 250-MW GreenGen IGCC was completed in 2015, but “planned phases to introduce CCUS [carbon capture, utilization, and storage] and construct a larger scale unit have apparently stalled,” Lockwood said.

But in Japan, research, development, and demonstration (RD&D) has continued in advanced coal technologies to further enhance coal power’s economic and environmental performance, Lockwood noted. More than 80% of the country’s roughly 43-GW utility coal fleet currently uses supercritical steam conditions (over half of which is classed as USC), and it remains heavily associated with high-efficiency low-emissions (HELE) coal technologies, he said.

Japan Investing Heavily on Transformative Coal Technologies

Japan’s leadership in developing and deploying HELE technologies was initially motivated by economics and security of supply considerations after the country closed most of its nuclear plants in Fukushima’s aftermath. But in recent years, USC technology “has become a key element of Japan’s CO2 emissions reduction strategy,” he said. The country’s 2013 revision of the Energy Conservation Act, for example, requires that new coal units achieve greater than 42% efficiency on a gross higher heating value (HHV—or more than 44% on a lower heating value [LHV]) basis, with some exceptions.

In the early 2020s, meanwhile, the government has set out to achieve the practical use of advanced USC and IGCC plants, which it says are capable of achieving efficiencies greater than 46%. As notably, Japan is spearheading a demonstration of integrated gasification fuel cell (IGFC) technology, which Lockwood describes as an “innovative variant on the IGCC plant” that uses coal-derived hydrogen in a fuel cell.

Backed by Japan’s New Energy and Industrial Technology Development Organization (NEDO), the 166-MW Osaki CoolGen Project will integrate an already demonstrated oxygen-blown IGCC technology with carbon capture, and then integrate that system with solid oxide fuel cells. Oxygen-blown IGCC, Osaki CoolGen says, is essentially the process to gasify coal and generate syngas with carbon monoxide and hydrogen as its main components. A demonstration in 2018 showed that the process can achieve “a net thermal efficiency of approximately 46% on a commercial plant, and could expect to cut CO 2 emissions by approximately 15%” compared to a USC project, Osaki CoolGen said. While the project is currently in detailed design and construction, the entity anticipates that the full IGFC demonstration will begin in fiscal year 2022.

Because Japan is looking to export these technologies to emerging economies, over the near term at least, successful operation of the new Nakoso and Hirono units “could lead to a new wave of IGCC deployment around the world,” Lockwood said. However, in parallel, interest is growing in coal gasification with CCUS as a low-cost source of hydrogen, and that is also helping drive other IGCC projects around the world, he said. “Two of the projects funded under the latest round of the U.S. DOE’s Coal FIRST initiative are associated with coal gasification, with a view to producing both low-carbon power and hydrogen. There is also potential for IGCC to play a role in India’s current drive to expand coal gasification capability, known as ‘the Methanol Economy,’ ” he said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Updated (June 1): To add subheads, and correct details about existing IGCC plants around the world. TECO confirmed the Polk plant has not been retired, while a DOE official suggested the Wabash plant’s future will involve hydrogen production and combustion. Also included in the list of existing large-scale IGCC projects are the 400-MW Vresová project in the Czech Republic, and Korea Western Power Co.’s 300-MW Taean pilot plant.