As the world combats a health pandemic, it is simultaneously fighting a drawn-out battle with climate change. As the Paris agreement reaches its fifth year, the UK, Germany, Netherlands, Japan, and other countries remain committed to finding new solutions, technologies, and sources of renewable energy to meet their ambitious 2030 and 2050 net-zero carbon emission goals.

One cost-effective way to reduce global warming is through the implementation of woody biomass into the global energy system. In fact, sustainably sourced wood biomass has been proven to play a significant, supplemental role as a dispatchable and reliable, non-fossil energy generator for countries around the world.

The woody biomass and bioenergy industries make up 60% of the European Union’s (EU’s) renewable energy, equate to $107 billion in U.S. gross domestic product, and as a group are part of a forestry industry that supports more than 2.9 million jobs across the U.S. Woody biomass has become a leading supplier of the world’s low-carbon energy supply, lowering carbon emissions by as much as 85% on a lifecycle basis when compared to coal. As a leading global energy company specializing in sustainable wood bioenergy, Enviva is providing an inside look into good biomass production, operations, and maintenance.

Finding and Sourcing From the ‘Right’ Forests

Enviva produces about 3.5 million metric tons of wood pellets per year (Figure 1) to supply essential fuel for power utility companies across the globe, including the UK and EU. It sources its low-grade wood fiber from private landowners in the U.S. Southeast, a region that produces about one-fifth of the wood used worldwide each year. To put the scale of the wood sourced in perspective, every year, only 2% of the forests in the southeastern U.S. are harvested, while the remaining 98% of forests continue to grow and store carbon.

|

|

1. Enviva’s sustainable wood pellet production plant in Sampson, North Carolina, produces about 555,000 metric tons of wood pellets per year. Courtesy: Enviva |

The fiber used for wood pellets comes from low-value wood, treetops, limbs, thinning practices, and sawmill residues from planned traditional timber harvests. However, Enviva does not believe all forest biomass is suitable for energy use, and there is a difference between “good biomass” and “bad biomass.” Good biomass is sourced from forests and feedstocks that are sustainably harvested. In this vein, Enviva does not support biomass production in the U.S. or elsewhere around the world that causes deforestation, degrades forests that have high carbon stocks, threatens endangered species, harms biodiversity, or diminishes water quality.

In fact, Enviva works with local and national conservation organizations to ensure they only source from forest landscapes that are stable or increasing, and its sourcing does not negatively impact areas with high conservation value. Enviva does not source from old-growth forests, protected forests, or forests that are harvested for land use conversion. The company strictly follows its responsible sourcing policy for its biomass to ensure positive outcomes for forest landscapes in the future.

Pelletizing

After sourcing low-value wood, the pelletizing process begins. From a high operations level, the low-value wood goes through a manufacturing process that entails drying the wood, reducing it to smaller pieces, and then pushing it through a specialty press to make a pellet (Figure 2). Enviva’s wood pellets are 100% plant matter and no chemicals are used in the process (Figure 3). In fact, during the extrusion process, the wood is pushed through a high-pressure press that causes the lignin, the natural adhesive in the wood, to melt and hold each pellet together, eliminating the use of synthetic glue.

|

|

2. An up-close view of Enviva’s extrusion process, where the wood is pushed through a high-pressure press that causes the lignin to melt, holding each pellet together and eliminating the addition of any chemicals to the pelletizing process. Courtesy: Enviva |

Although the process seems straightforward, it is quite complex, as pellet mills are working with a living, organic material that has several underlying variables to consider. Unlike an automotive assembly line, pelletizing wood is not a one-size-fits-all automated manufacturing process. Operational discipline is essential when it comes to pelletizing wood. Plant staff need to consider the type of wood, as well as the life-phase of each limb or sawmill residue collected. Once the above variables are identified, the raw materials are then separated into piles based on similar genetic and environmental traits, and used to form a blend that has to be strictly managed.

|

|

3. A tray of sustainably sourced wood pellets that will be exported to power and heat generators in the UK, Europe, and Japan. Courtesy: Enviva |

For this reason, Enviva has developed its own quality laboratories and partners with several universities on modeling, chemical composition research, and product testing to accurately predict pellet behavior and energy content. Because pellet processing dies can take up to 14 weeks to design and develop, there is little room for error in the production process. To further ensure excellence in safety, sustainability, compliance, quality, reliability, and productivity, Enviva continuously reviews and revises its production processes and standards to create energy-dense, low-moisture, and uniformly sized wood fuel that provides efficient, reliable combustion for customers.

Air Quality and Carbon Emission Guidelines

Enviva pellet manufacturing plants are designed and operated to meet or exceed air quality permitting requirements. To ensure that air standards are met, Enviva utilizes technology, best engineering practices, and state-of-the-art air emission controls to minimize emissions from its manufacturing process. The company builds and operates plants (Figure 4) that are the most “controlled” wood pellet plants in the world, ensuring compliance with both stringent Clean Air Act requirements and varying state laws. The company also ensures the destruction of volatile compounds, preventing harmful air pollutants from entering the atmosphere.

|

|

4. A group of Enviva associates overlook the company’s sustainable wood pellet processing plant in Cottondale, Florida. The company utilizes technology, best engineering practices, and state-of-the-art air emission controls to minimize emissions from its manufacturing process. Courtesy: Enviva |

As a whole, the pellet industry is still fairly young and the air emission data sets for equipment and processes are still evolving. For this reason, Enviva has deployed a large amount of investment and resources to better understand emissions associated throughout the manufacturing process, and evaluate various control scenarios and settings to remain compliant, as well as minimize the overall environmental impact on the local communities in which it operates.

To further reduce the carbon footprint associated with the wood pellet supply chain, Enviva’s facilities are strategically located in areas that minimize transportation from forest to plant to port. For example, all Enviva plants operate in the most attractive wood fiber regions in the U.S., in addition to being located near deep-water marine storage terminals for shipping.

|

|

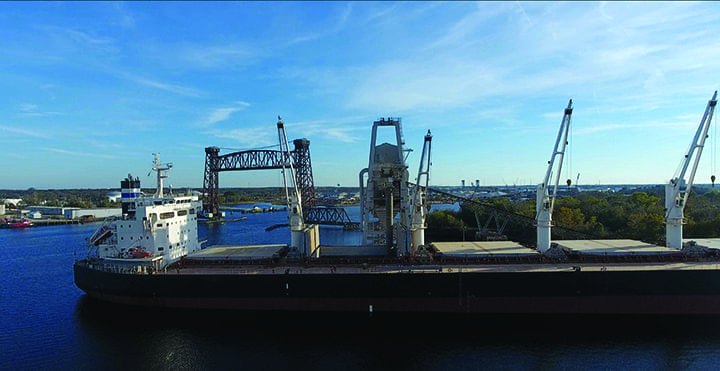

5. Large bulk cargo ships, such as this one at the Port of Chesapeake in Virginia, provide an energy-efficient mode of transportation for the export of wood pellets from the U.S. to the UK, Japan, and other countries. Courtesy: Enviva |

Enviva’s customers are power and heat utility companies in the UK, Japan, and other countries primarily in the EU, Asia, and the Caribbean. To transport its product to these countries, Enviva has identified the most energy-efficient mode of transportation with the least environmental impact, in this case large bulk cargo ships (Figure 5). By producing pellets and holding them, by the metric ton, in large storage domes next to ports, Enviva reduces the number of trips it takes to transport materials across the ocean. Enviva’s low “to-port” transportation costs were designed to maximize cost-effectiveness and efficiency while delivering the product in bulk to customers around the world.

Future Impact and Outcome

Since its inception in 2004, Enviva has innovated, learned, and expanded to provide reliable, sustainable, scalable wood pellets to customers around the world at scale. To date, the market remains strong for the wood pellet industry, as many European and Asian countries have instituted aggressive goals to reduce greenhouse gas emissions and meet international net-zero carbon emission targets by 2050. According to the International Energy Agency’s forecast, bioenergy will be the world’s fastest-growing renewable energy source over the next five years, making it the world’s largest renewable energy resource and an essential player in the global energy transition.

As the world’s largest producer of industrial wood pellets, Enviva expects to continue finding new efficient, effective, and sustainable ways to supply essential, renewable, low-carbon fuel for power utility companies across the globe.

—Thomas Meth is executive vice president and co-founder, and Chris Seifert is vice president of environmental health and safety at Enviva.