World’s largest PV plant now in Portugal

The world’s largest solar photovoltaic (PV) electric generating plant—at 11 MW—has come on-line in sunny Portugal.

The project, in the city of Serpa, 124 miles southwest of Lisbon, uses ground-mounted concentrator cells to track the sun as it moves across the sky during the day. GE Financial Services financed the deal and owns the project, PowerLight Corp. (www.powerlight.com) designed and developed it, and Portugal’s grid buys its output.

PowerLight, a manufacturer of silicon solar PV cells, is a subsidiary of SunPower Corp., which itself is a subsidiary of chip maker Cypress Semiconductor Corp. The project’s solar panels come from SunPower, Sanyo, Sharp, and Suntech.

The plant (Figure 1), which covers 150 acres, cost $78.5 million to develop, according to press accounts. Portions of it began operating in January, and the full plant began running in March. Its 52,000 panels make it the largest PV plant in the world, according to the developers (there are larger solar thermal-electric projects). The panels provide a capture surface area of 90 acres.

1. Power field. This plant in Serpa, Portugal, owned by GE Financial Services and designed and developed by PowerLight Corp., is now the world’s largest photovoltaic power plant, at 11 MW. Its PV arrays cover 92 acres of the 150-acre site. Courtesy: Power Light Corp.

"This is the most productive solar plant in the world," said Howard Wenger of PowerLight. "It will produce 40% more energy than the second-largest one, Gut Erlasse in Germany."

Iatan 2 construction may resume

After a six-year hold, construction could resume on the 850-MW Iatan 2 coal-fired power unit north of Kansas City as a result of a settlement between Kansas City Power & Light (KCP&L) and two local environmental and consumer groups.

The key to the agreement among the utility (a Great Plains Energy subsidiary), the Sierra Club, and concerned Citizens of Platte County is KCP&L’s commitment to try to obtain offsets for the carbon dioxide emissions from the plant, according to their joint news release. The offsets will take the form of new, renewable generation, reductions in CO2 emissions from existing plants, and energy conservation and efficiency improvements.

"We believe there is significant potential through new energy technology and innovative approaches to improve the environment and offer additional value to our customers across the Kansas City region," said Mike Chesser, CEO of Great Plains. "This is especially true with energy efficiency programs and wind generation, which we already have been deploying through our comprehensive energy plan developed in 2005."

Under the deal, KCP&L will:

- Add 400 MW of wind power capacity, at sites not yet determined, by 2012. KCP&L has an existing 100-MW wind farm in southwestern Kansas.

- Reduce demand by 300 MW by having businesses and communities participate in energy-efficiency programs.

- Reduce its overall CO2 emissions 20% by 2020.

- Conduct a study with the Sierra Club on "options, including retiring, re-powering, or upgrading" its coal-fired Montrose plant. Montrose has three 187-MW pulverized coal units that entered service between 1958 and 1964.

- Implement net metering in the KCP&L service territory.

KCP&L estimates that these steps will offset the 6 million tons of CO2 that Iatan 2 would produce annually. The 850-MW unit will be located next to Iatan 1, a 750-MW unit that was commissioned in 1980 (Figure 2). The settlement requires state regulatory approval.

2. Iatan redux. Construction of the 850-MW Iatan 2 coal-fired unit in Missouri may resume after a six-year hiatus. Shown here is its older brother, the 750-MW Iatan Unit 1, born in 1980. Courtesy: Kansas City Power & Light

Construction of Iatan 2 began in 2001 but was quickly halted by lawsuits and additional administrative strategies launched by the Sierra Club and the Platte County citizens’ group.

Bruce Niles, an attorney for the Sierra Club, told the Associated Press, "KCP&L has raised the bar, and it will be impossible for any other responsible utility to ignore global warming."

Allegheny to scrub Fort Martin plant

Allegheny Energy has signed an engineering, procurement, and construction agreement with Washington Group International (www.wgint.com) to add a flue gas scrubber to Allegheny’s coal-fired Fort Martin power station.

According to Allegheny, installing a scrubber on the 1,107-MW plant (Figure 3) near Morgantown, W.Va., will reduce sulfur dioxide emissions by 95%. Washington Group said the job is worth $550 million. In addition to the environmental benefits, said Washington Group, the scrubber will enable the plant to burn more local, high-sulfur coal. The retrofit is expected to be completed in 2009.

"Scrubber installation at Fort Martin is an integral part of our environmental improvement plans," said Paul J. Evanson, Allegheny Energy’s CEO. "This project will bring cleaner air and more jobs to West Virginia, and allow us to use more locally sourced coal."

3. Scrub-a-dub-dub. Allegheny Energy has hired Washington Group International to add a flue gas scrubber to its 1,107-MW Fort Martin coal-fired plant near Morgantown, W.Va. Courtesy: Allegheny Energy

Other environmental programs at Allegheny, totaling $1.4 billion, include:

- Having Washington Group add a scrubber to the 1,710-MW Hatfield’s Ferry power station 40 miles south of Pittsburgh.

- Enhancing the chimney and ductwork of the 1,300-MW Pleasants power station at Willow Island, W.Va., to improve flue gas scrubbing. Allegheny says the work "will significantly reduce sulfur dioxide emissions and mitigate flyash dispersal issues."

- Adding low-sulfur Powder River Basin coal to Allegheny’s fuel mix, reducing the utility’s total emissions from coal combustion. Allegheny plans to slash its total sulfur dioxide emissions by more than 275,000 tons per year.

The Fort Martin job is another sign of boom times for Washington Group. The company recently announced a nationwide hiring spree that it is hoped will add some 1,000 employees this spring.

TVA will clean up John Sevier plant

Tennessee Valley Authority says it will spend some $350 million to upgrade NOx and SO2 controls at its 712-MW John Sevier plant in Rogersville, Tenn.

The giant regional power agency—an arm of the federal government—says it will install selective noncatalytic reduction (SNCR) units and flue gas scrubbers at the plant, which burns mostly high-sulfur eastern coal, to reduce its emissions by up to 95%. SNCR and flue-gas desulfurization systems will be added to all four units of the Sevier plant (Figure 4). Sevier is one of the elderly TVA coal plants that, along with nuclear units, have long been the biggest contributors to the utility’s baseload capacity.

4. John Sevier gets greener. Tennessee Valley Authority will spend $350 million to upgrade NOx and SO2 controls on its 712-MW coal-fired John Sevier plant in Rogersville, Tenn. Courtesy: TVA

Tom Kilgore, TVA’s CEO, said, "The air in east Tennessee continues to improve and is cleaner today than it has been in the past three decades, due to TVA’s continued commitment to clean air. We have reduced our emissions of sulfur dioxide across the system by 80% since 1977, and those of nitrogen oxide during the summer ozone season by 81% since 1995."

TVA said the first of the SNCR units will be installed on John Sevier Unit 1 this summer. The other three, to be put in place by 2010, are expected to reduce the plant’s overall NOx emissions by 35%. Installation of the scrubbers at Sevier will begin next year and will be completed in 2012. TVA added that it is now burning some low-sulfur coal at the plant to lower its SO2 emissions.

When the Clean Air Act was enacted in 1970, TVA argued that, as a federal agency, it was not subject its limits, which applied to state-regulated power plants. In 1977, under the direction of then-TVA chief S. David Freeman, the agency agreed to a massive cleanup of its coal-fired capacity. Since then, according to TVA, it has spent $4.6 billion to comply with federal air emissions rules.

TVA now operates seven flue-gas scrubbers on its largest coal-fired plants and is building scrubbers on three others, to be operational by 2010.

Siemens to build big Dutch CC plant

Siemens Power Generation has won a turnkey contract to build and maintain an 870-MW gas-fired combined-cycle power plant in Vlissinger-Oost, the Netherlands. According to the company, the deal is worth about $733 million. The Sloecentrale project, a joint venture of the Dutch firm Delta Energy and Paris-based Électricité de France, is expected to be operational in the spring of 2009.

In a press release, Siemens (www .powergeneration.siemens.com) says the Sloecentrale plant will be the first built in the Netherlands since the 2003 Rijnmond Energy project, to which Siemens supplied key components. The nation restructured its energy market in 2002.

The Sloecentrale plant will be a greenfield project in the province of Zeeland in the southwest part of the country. Siemens will supply two SGT5 gas turbines (Figure 5), two SST5 steam turbines, two water-cooled generators, and electrical and instrumentation and control (I&C) equipment. The latter, in the form of the SPPA-T3000, will be the first fourth-generation I&C system in the Netherlands, says Siemens.

5. Siemens goes Dutch. Its SGTS turbine, says Siemens, is the most efficient gas turbine in the world, with a rating exceeding 60% in combined-cycle operation. Courtesy: Siemens Power Generation

Siemens Power Generation also announced that it will supply two steam turbine-generators to a Brazilian biomass plant 370 miles north of São Paulo, under a contract worth about $30 million. Pöyry Empreendimentos—a subsidiary of VCP, one of the largest cellulose producers in the Americas—placed the order. The steam from the two gensets will come almost entirely from burning biomass residue at the local pulp mill, and their excess electricity will be sold into the local grid.

According to Siemens, when the pulp and paper mills are at maximum capacity the two gensets will generate 160 MW. Rene Umlauft, head at industry turbines at Siemens PG, said, "The high efficiency of the turbines and the utilization of biomass mean that Siemens is providing not only a very economical solution, but also very environmentally-friendly energy."

Finally, Siemens said it has landed several orders worth over $56 million for compressors and compressor trains from Chinese chemicals and iron-and-steel manufacturers. Siemens will supply two trains for a pure terephtalic acid project in northeastern China, two high-pressure air compressors and two nitrogen product compressors for an iron and steel mill 135 miles northeast of Beijing, and a compressor train and a high-pressure integrally geared compressor for a chemical plant in southeast China.

Siemens now uses complex simulations to help develop its very efficient combined-cycle power plants. The research magazine Pictures of the Future reports that the company’s designers rely on computer models to optimize the shape of turbine blades and the flow around them. According to Siemens, this application, along with continued improvement of materials, will soon raise the fuel efficiency levels of the company’s combined-cycle plants above 60%, from today’s average of 58%.

Connecticut blesses six fuel cell projects

The Connecticut Clean Energy Fund (CCEF) would like to subsidize six projects to be powered by CFC molten-carbonate units from FuelCell Energy Inc. (FCE) as part of a program to increase use of renewable energy in the state. The projects have a combined capacity of 68 MW.

Under the state program, the two distribution utilities in Connecticut must endorse the selections and arrange long-term agreements to purchase the projects’ output. Under a 2003 law, the utilities must buy at least 100 MW of renewable energy.

The names of the projects chosen are:

- ERG Milford. This 7.9-MW project—a joint venture of FCE, Enbridge Inc., and Southern Connecticut Gas—will couple a 7.2-MW fuel cell with a 1.5-MW pipeline turbo expander. Natural gas cools when it transfers from interstate pipelines to distribution lines. The Milford project will capture the heat from the DFC3000 fuel cell (Figure 6) and use it to warm the gas. FCE expects the project to have an electrical efficiency of 60%.

- Elemental Power Group, Danbury. This 19.6-MW project will consist of eight fuel cells and incorporate organic Rankine cycles to convert the heat from the fuel cells into additional electricity, raising overall system efficiency to 47%. The power will be sold to Connecticut Light & Power. Elemental Power is a joint venture of Marubeni Power of New York and Catamount Energy of Vermont.

- Elemental Power Group, Bridgeport, a clone of the Danbury project, will deliver power to United Illuminating Co. (UI).

- Bridgeport Fuel Cell Park. This 13.7-MW project will use a remediated brownfield site in an urban development area and deliver power to UI.

- Hospital Energy Development, Stamford. This 4.6-MW project will supply heat and power to Stamford Hospital and power to the New England grid.

- Hospital Energy Development, Waterbury, a duplicate of the Stamford project. FCE projects that both will achieve 60% electrical efficiency.

6. Fuel cells compete in Connecticut. These FuelCell Energy DFC3000 fuel cells feature prominently in a Nutmeg State program to increase use of renewable energy. Courtesy: FuelCell Energy

The six FCE fuel cell projects are among 11 renewable-power proposals that the Connecticut program has picked for further development. R. Daniel Brdar, CEO of FuelCell Energy (www.fce.com), said the value of the projects in Connecticut will be "more than $200 million if all are accepted. The volume will enable additional cost reduction and the expansion of our facilities in Connecticut and elsewhere." FuelCell Energy is headquartered in Danbury, Conn.

DOE approves IGCC plant in Florida

The U.S. Department of Energy has cleared the way for construction of a $569 million, 285-MW integrated gasification combined-cycle (IGCC) power plant in Orlando, Fla. The DOE will provide 41% of the funding, or $235 million.

Energy Secretary Samuel Bodman signed the formal "record of decision" on the project, one of three moving forward under the agency’s $2 billion, 10-year clean-coal demonstration program. The Florida plant will be co-owned by Southern Power (Southern Company’s unregulated subsidiary), the Orlando Utilities Commission (OUC), and Kellogg, Brown and Root (www.kbr.com). It will be located at OUC’s existing Stanton Energy Center near Orlando.

The key to the project is Southern Energy Services Inc.’s transport gasifier (Figure 7). In a July 2005 presentation at a meeting of the DOE’s National Energy Technology Laboratory, Southern noted that the transport gasifier technology has been "used successfully for over 50 years in the petroleum refining industry."

7. Coal to gas. Southern Company’s transport gasifier is the linchpin of a $569 million, 285-MW IGCC project that the U.S. DOE is supporting in Orlando, Fla. This schematic shows the plant’s major components and flows. Source: National Energy Technology Laboratory

Unlike conventional oxygen-blown entrained-flow gasifiers, the transport gasifier can be run in air-blown mode, reducing the need for oxygen separation equipment. According to the DOE, the gasifier technology "cost-effectively uses low-rank coals, as well as coals with a high moisture or high ash content. These coals comprise half of proven U.S. and world reserves."

Two other projects are moving forward in the second round of the DOE program. Excelsior Energy Inc. and ConocoPhillips are proposing the 531-MW Mesaba Energy Project at Hoyt Lakes, Minn. NRG Energy and Pegasus Technologies Inc. have proposed demonstrating advanced mercury and multipollution controls on an existing 890-MW NRG plant in Texas that burns lignite and Powder River Basin coal.

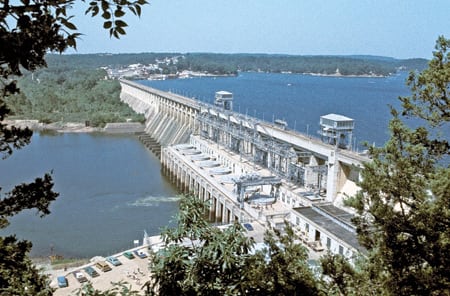

FERC relicenses Osage hydro plant

In late March, the Federal Energy Regulatory Commission (FERC) relicensed for 40 years AmerenUE’s Osage hydro project, a 176-MW unit (Figure 8) on the Osage River in Missouri. The plant had been operating on a temporary, one-year license while the case was pending at FERC.

8. Osage gets new life. The Federal Energy Regulatory Commission has relicensed AmerenUE’s 176-MW Osage hydro for 40 years. Courtesy: AmerenUE

The licensing process for the project began more than five years ago, according to the Lake Sun Leader newspaper in Missouri. In a press release, FERC said, "The new license assures the continued operation of a reliable power source in the region while minimizing downstream erosion and protecting water quality, fisheries, wetlands, recreation, and historical resources at the project."

Like many hydro relicensing applications, the Osage project generated some controversy. Most of it involved management of the Lake of the Ozarks’ 1,150-mile shoreline. The project created the lake. FERC approved an uncontested settlement agreement as part of the new license.

The new 40-year license requires AmerenUE "to file a shoreline management plan with the commission within one year to ensure that shoreline development activities within the project boundaries are consistent with the license." According to the local newspaper, the utility’s original shoreline management plan drew fire from "lakefront property owners, realtors, bankers, and others who oppose the plan" because of its restrictions on dock placement.

Among the conditions that FERC imposed in the new license are generating unit upgrades, fish protection, improvements to recreational facilities, a recreation management plan, an operations and flow-management plan, monitoring of downstream shoreline erosion, and monitoring of lake level, inflow, and discharge.

A nanotech perpetual motion machine?

It may or may not be a perpetual motion machine, but at the least it’s a major breakthrough in nanotechnology. Three researchers at Georgia Institute of Technology report in a recent issue of Science magazine that they have developed a direct-current nanogenerator that can be driven by an external mechanical energy source such as ultrasonic waves, vibration, or blood flow.

In other words, the nanogenerator needs no external source of electrical energy, but can generate continuous current from the world around it. The researchers, led by Zhong Lin Wang (Figure 9), regents’ professor in Georgia Tech’s School of Materials Science and Engineering, say they have demonstrated conversion of nanoscale mechanical energy into DC current by piezoelectric zinc-oxide nanowires (Figure 10), which they describe in a news release as "zig-zag" plates.

9. Wizard Wang. Zhong Lin Wang, regents’ professor of materials science and engineering at Georgia Tech, led the development of a novel nanogenerator that can be powered by forces in the world around it. Courtesy: Georgia Institute of Technology

10. World’s smallest power plant? How many watts can dance on the head of a nanowire? Courtesy: Georgia Institute of Technology

"This is a major step toward a portable, adaptable, and cost-effective technology for powering nanoscale devices," Wang said. "There has been a lot of interest in making nanodevices, but we have tended not to think about how to power them. Our nanogenerator allows us to harvest or recycle energy from many sources to power these devices."

The demonstration began with the growing of vertically aligned nanowires about a half-micron apart on a base of gallium arsenide, sapphire, or flexible polymer. Then, a layer of zinc-oxide was grown on a substrate and coupled with the silicon zig-zag electrodes, whose tips are coated with electrically conducting platinum. The assembly serves as the electrode.

The researchers then lowered the electrode on top of the nanowire array, leaving enough space so the nanowires can flex within the gaps created by the tips. As the nanowires are forced into contact with the electrode tips by sound waves or an input of mechanical energy, they create an electrical current in the nanoampere range. Combining enough of the tiny currents produces enough electricity to perform some work. As Georgia Tech describes it, the zig-zag electrode "serves as a Schottky barrier for hundreds or thousands of wires simultaneously, harvesting energy from the nanowire arrays." A Schottky barrier is a metal semiconductor junction with the characteristics of a rectifier.

Zinc-oxide, the researchers note, is nontoxic and compatible with human tissue (it’s the basis of most sun-block products). So if the nanogenerators were implanted, they could power medical devices or continuous, real-time blood pressure monitors.

They could also have more mundane applications. Said Wang, "If you had a device like this in your shoes when you walked, you would be able to generate your own small current to power small electronics. Anything that makes the nanowires move within the generator can be used for generating power. Very little force is required to move them."

POWER digest

News items of interest to power industry professionals.

Reprocessing group adds a partner. Japan Nuclear Fuel Ltd. (JNFL) has joined an Areva-led consortium aimed at winning support from the U.S. DOE’s Global Nuclear Energy Partnership. The other members are Washington Group International and BWX Technologies Inc.

The DOE is looking for industry interest in reviving spent-fuel reprocessing, using technology resistant to nuclear arms proliferation. The administration, with its penchant for euphemism, consistently refers to this as "recycling."

JNFL brings to the table its experience developing and operating the Rokkasho reprocessing plant in Japan. The company is testing what it says is the world’s newest commercial reprocessing plant, including implementing full-scale International Atomic Energy Agency safeguards.

Areva NP (www.areva.com) is the world’s largest nuclear fuel cycle company. Washington Group (www.wgint.com) has been a contractor for the DOE and its predecessor, the Atomic Energy Commission, since 1942. BWX Technologies (www.bwxt.com), a subsidiary of McDermott International, has 50 years’ experience with nuclear fuel and holds a U.S. Nuclear Regulatory Commission license to make and handle highly enriched uranium.

EPC gets Kansas contract. Midwest Energy Inc. has named Burns & McDonnell the engineering, procurement, and construction contractor of a 76-MW peaking project to be sited near Hays, Kansas. Construction of the $60 million plant was scheduled to begin this spring, and it is expected to be finished by June 2008, to meet summer peak loads.

The Goodman Energy Center will be powered by nine 8.4-MW gas-fired internal combustion engines from Wärtsilä (www.wartsila.com). All will be equipped with selective catalytic reduction technology to reduce their NOx emissions. The engines use a closed-loop cooling system that consumes no process water and requires no wastewater treatment or disposal. The Wärtsilä engines can ramp up to 25% power within two minutes and to full output in 10 minutes, says Midwest Energy.

Burns & McDonnell (www.burnsmcd.com) helped Midwest manage a 2006 request for proposals for varying amounts of baseload, intermediate, and peaking capacity. The utility got 14 offers. Wärtsilä’s proposal for the Goodman center, said Midwest, represented "the lowest-cost option for peaking capacity."

E.ON gives up on Endesa. In April, German energy giant E.ON gave up a year-long pursuit of the Spanish electric utility Endesa. It conceded that it could not outbid a rival suitor, a team consisting of Spanish construction company Acciona and Italian energy giant Enel. E.ON, which has been on an acquisition binge for several years, had offered $56.5 billion for a majority share of Endesa.

The arrival of Acciona and Enel as rival bidders forced E.ON to back down. In a written statement, Dr. Wulf H. Bernotat, E.ON’s CEO, said, "Acciona’s and Enel’s involvement in Endesa has made our original goal of acquiring a majority stake in Endesa impossible. Obtaining a minority interest would have led to a stalemate between the shareholders and triggered unpredictable lawsuits."

In return for leaving the Endesa field clear for Acciona and Enel, E.ON will acquire generating assets from Acciona and Enel in Spain, Italy, and France that are worth, according to E.ON, $14.4 billion. As a result, E.ON will become the fourth-largest power producer in Spain in Italy and the third-largest in France.

According to a report by the French news agency AFP, E.ON still has a pile of $40 billion in cash and debt for future acquisitions. AFP reported that Bernotat told the E.ON board on the day after the Endesa deal died, "We are going to have more opportunities to expand in the future in other markets, such as Russia."

The Wall Street Journal, reporting on the E.ON story and other European merger and acquisition activity, said, "Behind all the deals is a big collision between Europe’s new push for a unified marketplace and the national pride of Europe’s politicians. Starting July 1, the European Union’s power sector will be officially flung open to competition, allowing utility companies from any of the bloc’s 27 member nations to sell electricity in any other."