Coal used for power generation has been the cornerstone of economic development, social progress, and a higher quality of life around the globe and is now fueling the 21st-century economic miracle rapidly unfolding in China. Meanwhile, China is leading the world in coal-fired plant efficiency and the deployment of clean coal technologies.

Over the past 20 years, coal has increased its share of China’s total power generation from 72% to 80%, providing electricity for the first time to more than 500 million people. China’s electrification rate is now 99%, compared to less than 60% in 1990, while annual per capita consumption has soared from 500 kWh to 2,900 kWh. China more than tripled its share of global coal-based generation from 11% in 1990 (471 TWh) to 37% in 2011 (3,170 TWh). The economic benefits for the Asian nation are obvious. For example, the World Bank’s Human Development Indicators show that around 85% of the global population that rose out of poverty since 1990 was Chinese.

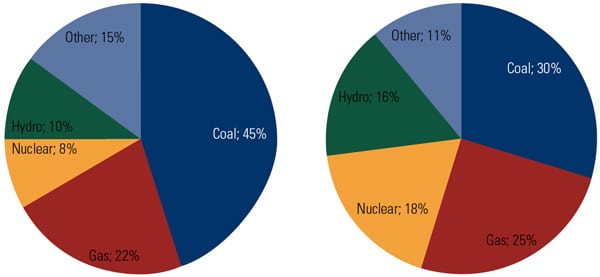

As the world strives to eliminate energy poverty while simultaneously meeting rising demand, China’s unprecedented progress has set an example. Consider projections of future generation sources made by the International Energy Agency’s (IEA’s) World Energy Model and the U.S. Energy Information Administration’s (EIA’s) National Energy Modeling System (Figure 1). The bulk of new demand will occur in the developing world, where massive amounts of affordable and reliable power are required to lift hundreds of millions into the modern age. In short, the world will continue to use coal, and consumption will significantly expand for decades to come.

|

| 1. Different projections. Reference scenarios for incremental sources of electricity for China through 2030 differ but agree that coal will remain a major player. The International Energy Agency’s World Energy Outlook 2011 numbers are shown on the left, and U.S. Energy Information Administration’s International Energy Outlook 2011 numbers are shown on the right. Sources: IEA, EIA |

Clean coal technologies will be the means to meet both burgeoning global energy demand and climate policy goals. Some are expected to be deployable at scale in the early-2020s, while the evolving technology of carbon capture and storage (CCS) and near-zero emissions are expected to follow shortly thereafter. Until that time, highly efficient and large supercritical (SC) and ultrasupercritical (USC) coal plants can meet immediate needs while significantly reducing emissions intensity.

In fact, efficient plants are a prerequisite for retrofitting with CCS, because the capturing, transporting, and storing of a plant’s carbon dioxide (CO2) consumes energy. The teaming of higher efficiency coal-fired technologies and CCS will unlock the full value of coal. In this race, China enjoys a global lead.

China’s Clean Coal Technology Plans and Achievements

U.S. Secretary of Energy Steven Chu reports that advanced coal-based power plants are one of the seven energy arenas in which China is outpacing the U.S. Here are some of the ways in which China is leading the race.

Initiated in 2007, China’s dual programs of Large Substituting for Small (LSS) and Energy Conservation Power Generation (ECPG) are expected to result in the decommissioning of over 114 GW of small, inefficient plants and the addition of 112 GW of more efficient SC units. In short, China’s future growth in generation capacity centers on evolving from 300-MW and 600-MW subcritical boilers to larger and more efficient SC and USC boilers ranging in size from 600 MW to 1,000 MW. These advanced plants produce almost 40% fewer emissions than many existing coal plants, thereby making them cleaner. The rule of thumb is that a 1% increase in plant efficiency reduces emissions—such as CO2, SO2, NOx, and particulates—by approximately 2%.

According to the IEA, the average operating efficiency of the world’s existing coal plant fleet is under 29%. New SC plants, however, can achieve overall thermal efficiencies in the 44% range, and USC units can reach 46% to 48%. China has deployed some of the world’s most efficient coal power stations, such as Shanghai Waigaiqiao Unit 3, which has a peak efficiency of over 46%.

China is also rapidly proceeding with GreenGen, a $1 billion initiative in Tianjin to advance near-zero-emissions coal-based electricity with hydrogen production and CCS. The first phase of GreenGen came online at the end of 2011, and commercial operations are set to begin in 2016.

China’s 12th Five-Year Plan (2011–2015) aims to cut carbon intensity, the ratio between changes in CO2emissions and gross domestic product, by 17% (see “China’s 12th Five-Year Plan Pushes Power Industry in New Directions,” January 2012, available in the POWER archives at https://www.powermag.com). The nation is now installing some of the largest, most advanced coal units in the world using SC and USC steam conditions and modern SO2/NOx and dust control systems. According to the Asian Development Bank, “This has resulted in a significant reduction in coal consumption, greenhouse gas and other pollutant emissions, and impressive improvement in energy efficiency.”

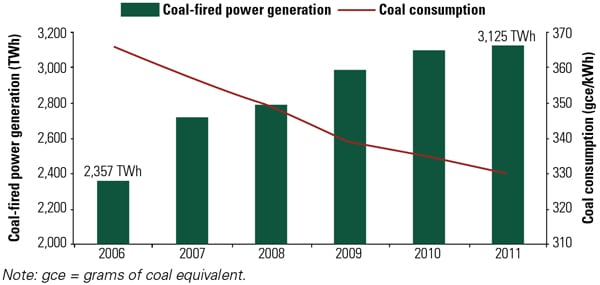

More than 500 small, inefficient thermal generating units, with the combined generating capacity of 14.4 GW, were decommissioned in the first year of LSS alone, and 43 million tons of coal and a corresponding 60 million tons of CO2were saved in the first two years. From 2006 to 2011, the nationwide average coal consumption for power generation plummeted from approximately 366 grams of coal equivalent (gce)/kWh to 330 gce/kWh, suggesting that the 320 gce/kWh goal for 2020 will easily be achieved (Figure 2).

|

| 2. The impact of increased future coal-fired power efficiency in China is significant. Sources: J. Mao, “How Does China Reduce CO2 Emissions from Coal Fired Power Generation?” The World Bank, 2009 Energy Week, Washington DC; Z. Xiliang, “Science Advance Relative to Energy Efficiency and Renewable Energy: Some Observations from China,” International Seminars on Planetary Emergencies, 2010; and International Energy Agency |

Over 80% of China’s orders for thermal power capacity are for 600-MW SC or 1,000-MW USC units, and the country now represents some 90% of the global market for advanced coal combustion power generation systems and associated environmental control systems.

Pulverized coal (PC) combustion is one of the most mature generation options, which has led Chinese policymakers to favor the most advanced PC technologies: SC and USC plants. For example, all four of the 1,000-MW coal-fired USC pressure boilers at Yuhuan had come online by November 2007. New units incorporate high-efficiency dust removal and desulfurization, and Yuhuan Units 1 and 2 are touted as the “world’s cleanest, most efficient and most advanced” PC units, with an efficiency rating of 46%.

Rapid deployment is required because China has limited availability of good sites for large-scale power plants, and USC PC units allow power generation companies, which are aggressively competing against each other, to expand their total capacity and utilize their sites more efficiently. In fact, all five of China’s largest power generation companies now have their own USC PC units.

As a pioneer in efficient boiler technology, the Babcock & Wilcox Co. (B&W) announced in September 2010 that B&W Beijing Co. will build two 1,000-MW USC coal-fired boilers for a large power plant project in Zhejiang province. The two Spiral Wound Universal Pressure (SWUP) boilers will use one of B&W’s most advanced and efficient coal-fired boiler designs.

The SWUP is engineered for both baseload and variable pressure load-cycling operation, as well as on-off cycling operation. The SWUP is unique in that the tubes in the furnace, from the lower furnace inlet headers to a location near the furnace arch, are wound around the furnace circumference rather than being vertical. This lets the fluid in the tubes pass through the various heat flux zones around the furnace, providing a more uniform outlet enthalpy. B&W’s spiral furnaces utilize multi-lead ribbed tubing to allow once-through operation at lower minimum loads. (See “Design Features of Advanced Ultrasupercritical Plants,” Parts I, II, and III in the March, May, and July 2012 issues of COAL POWER, available at http://www.coalpowermag.com.) Contract activities for the Zhejiang project are under way, and delivery is scheduled for late 2012.

Emerson Process Management will install its Ovation expert control system at two new 1,000-MW USC coal-fired generating units now under construction in China’s Anhui province. According to the company, the Ovation is now being used to automate and control processes and equipment at more than half the 1,000-MW units in China, including a number of USC plants. For both new units, the Ovation system will perform data acquisition, as well as monitor and control all major plant components, including the boiler, turbine, and generator. Unifying boiler and turbine operations offers many operational benefits, namely improved unit stability, responsiveness, thermal efficiencies, tighter control of operations, and a leaner view of key plant and turbine parameters. The system will also manage each unit’s modulating control system, sequence control system, electrical control system, furnace safety supervisory system, feedwater turbine control system, and flue gas desulfurization system.

Looking forward, China’s coal-based electricity will be increasingly clean. LSS and ECPG help ensure that only modern units get access to the power grid. The National Development and Reform Commission uses policy instruments and economic incentives to prioritize the scheduling of cleaner and larger coal plants.

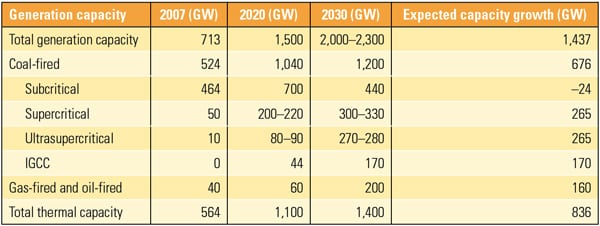

For example, in order to build a new 600-MW station, 420 MW of old capacity must be closed, and for a 1,000-MW new unit, at least 600 MW must be shuttered. Over the next decade, new power plants with a unit capacity of 600 MW and above will all be required to be advanced, roughly half of which will be USC. By 2030, subcritical units are expected to account for only 30% of China’s total thermal generation capacity, against more than 80% in 2007 (see table). The average efficiency of China’s coal-fired power plants is expected to increase from around 30% today to above 40% in 2030.

|

| Coal rising. The number and capacity of China’s advanced coal-based power plants is expected to grow significantly. Source: IEA, 2009 |

Follow the Leader

China has leveraged coal to virtually eliminate abject electricity deprivation. The country’s commitment to higher plant efficiency means more power, less fuel consumption, and a corresponding reduction in emissions intensity.

This model is being repeated in the other emerging giant, India, where power generation needs are staggering: 280 million Indians lack electricity, 600 million cook with wood or dung, and 900 million have no refrigeration. India’s Ultra Mega Power Projects will deploy larger and more efficient coal-fired SC units to narrow the gap between India’s low per capita power use (600 kWh/year) and that of the West (7,000+ kWh/year).

From 2009 to 2030, the IEA projects that India will increase its coal-based generation capacity from 92 GW to 290 GW—more than gas, nuclear, wind, and solar combined. Advanced coal power stations have lower operating costs due to their higher efficiency. Indeed, the United Nations (UN) finds that the capital cost of a SC plant is “more or less” the same as that of a subcritical plant, especially as economies of scale take hold.

Some 1,300 million people today lack access to electricity, the sine qua non of modern civilization. Unfortunately, the IEA projects that this number will only be reduced by a “shameful and unacceptable” 20%, to 1,036 million, by 2030. The effects of electricity deprivation are devastating. The UN reports that 25,000 children die each day—many from preventable causes that electricity helped eliminate in the West almost a century ago. Importantly, all eight of the UN Millennium Development Goals require access to electricity.

As they look toward the future, many in the global scientific and engineering community have turned their creative gaze to the safe management of CO2. Meanwhile, policies to achieve sustainability should look for ways to promote technological advancements that will offer us the ability to continue using our vast reserves of coal more efficiently and cleanly.

— Jude Clemente (judeclemente21@msn.com) is an energy analyst in the Department of Homeland Security, San Diego State University and a principal at JTC Energy Research Associates.