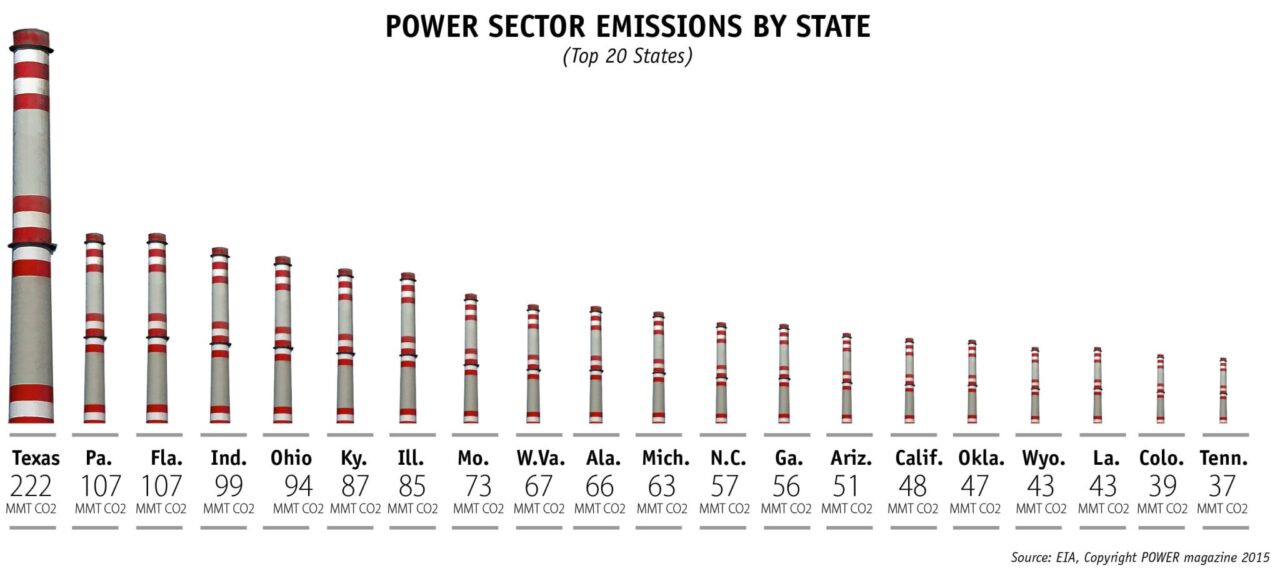

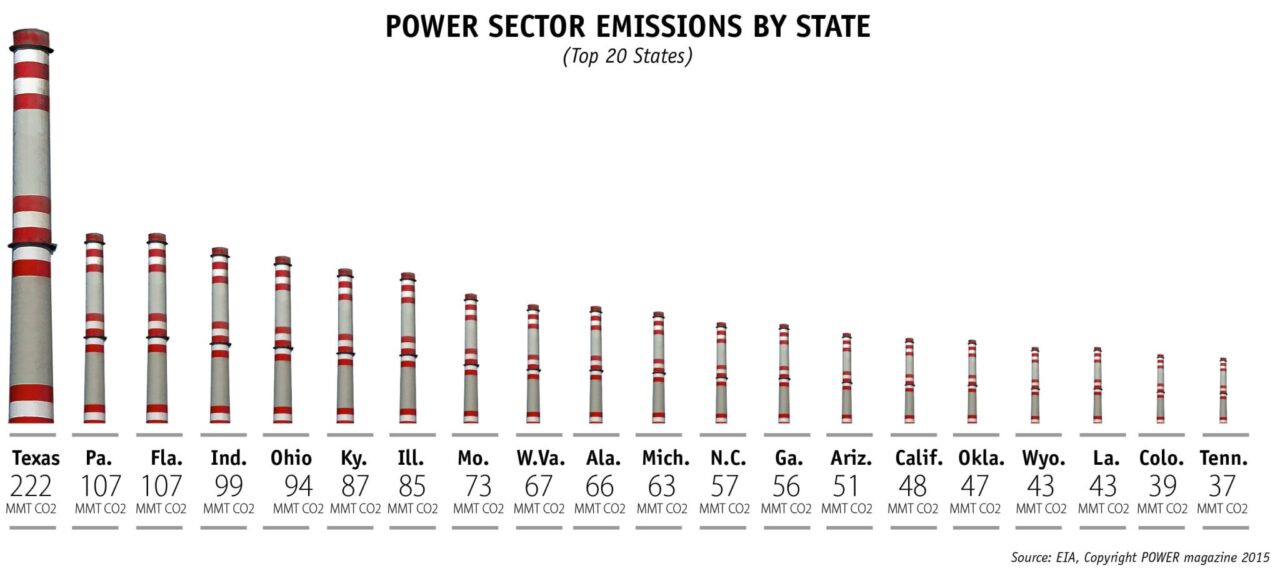

POWER's monthly infographic sheds light on power sector trends globally, and in 2015, it highlighted changes in plant retirements, sector revenues, rule costs, workforce, emissions technologies, and electricity costs, among…

Coal power plant design, construction, operation and maintenance, as well as legal and regulatory issues.

POWER's monthly infographic sheds light on power sector trends globally, and in 2015, it highlighted changes in plant retirements, sector revenues, rule costs, workforce, emissions technologies, and electricity costs, among…

Texas is the latest state to file suit against the Environmental Protection Agency (EPA) over its recently finalized standards for ozone. The state joins Arizona, Arkansas, Kentucky, New Mexico, North…

A status update and forecast for solar photovoltaic power in Greece, Croatia, and Italy. In the wake of the COP21 climate conference in Paris, many nations are announcing plans to…

A slowing of the Chinese economy and the diversification of its power sector, combined with a worldwide trend toward policies that favor renewable energy and the retirement of older, less-efficient…

As expected, President Obama vetoed two resolutions on Dec. 18 that would have blocked the Environmental Protection Agency’s (EPA’s) rules on CO2 emissions and halted the administration’s Clean Power Plan.…

North America's reserve margins are trending downward, even though electricity demand has generally fallen, the North American Electric Reliability Corp. (NERC) warned in a new report. The international regulatory authority…

In a major boost to the wind and solar industries, Congressional leaders agreed on a multiyear extension of renewable energy tax credits, which could provide several years of predictable policies,…

The Mercury and Air Toxics Standards (MATS) will remain in effect as the Environmental Protection Agency (EPA) works on a final cost finding, the U.S. Court of Appeals for the…

Coal ash utilization, which had stalled between 2009 and 2013 as the Environmental Protection Agency (EPA) prepared a final federal coal ash rule, increased significantly in 2014. According to the…

Delegates of 195 nations, including the U.S., on Dec. 12 reached a landmark deal at the Paris COP21 conference that commits the world to reducing greenhouse gas (GHG) emissions in…