Commercial and industrial businesses can get a boost from their electrical infrastructure by making their systems more dynamic, enabling new capabilities and control.

What do you need your electrical infrastructure to do? Chances are, it’s a lot more than ever before. We’re moving into a world where electrical power is no longer generated centrally. Instead, it can be generated locally, used, stored, or sold back to the utility. In this environment, we can view everything as a grid including your home, a manufacturing plant, an office building, a data center, and more.

How does “Everything as a Grid” work? The energy transition has created the need for more intelligent dynamic power systems. Traditional power generation sources are steadily being replaced by energy storage and renewables. This transformation is enabling local energy production, but also means electrical power must flow in two directions. Now, energy consumers can produce, consume, and sell energy back through a more dynamic grid.

Commercial and industrial businesses can take advantage of this paradigm shift by making their electrical infrastructure do a lot more to improve energy usage and the bottom line. Let’s take a look at what’s driving this transformation, what it looks like for commercial and industrial operations, and the business benefits you can achieve. How can you make your electrical system work harder for you?

What’s Driving the Need for an ‘Everything as a Grid’ Environment?

There are two fundamental trends upending the energy status quo. Electricity demand is trending up after a more recent flat period across developed economies. And, a centralized electricity supply is no longer the only reality.

Increased electricity demand is being driven by how buildings, data, and transportation are powered. By 2050, analysts expect a 50% increase in the share of energy provided to buildings. Transportation electrification is expected to increase global electricity demand by 27% in the next decade, according to the National Renewable Energy Laboratory’s “Electrification Futures Study.” Data and computing will require four times more electricity over the next decade.

At the same time, the old model of centralized electrical supply is just that—old. In the next 15 years, some analysts have said half the world’s electricity will come from renewable resources. More and more distributed energy resources (DERs) will be online and energy can be made locally and nearly anywhere. Behind-the-meter assets create a more dynamic grid with two-way power flow, and the potential for many different entities to produce, consume, and sell energy.

What does this mean? The energy transition is changing how we use electrical power and electrical infrastructure is evolving to enable this new reality. Multiple parts of the system need to be connected and dynamically controlled to ensure safety, resiliency, and cybersecurity.

How ‘Everything as a Grid’ Plays Out for the C&I Sector

By helping customers safely add more renewables, storage, and electric vehicle infrastructure to their energy mix, we’re empowering them to become more sustainable and resilient while lowering energy costs. It means commercial and industrial entities can get new capabilities from their electrical infrastructure. Let’s take a look at how this can work.

|

|

1. Eaton’s manufacturing plant in Wadeville, South Africa, had solar generation in place, and by adding energy storage and microgrid control the company has turned the facility into what it calls a “Plant as a Grid.” Courtesy: Eaton |

At Eaton’s manufacturing plant in Wadeville, South Africa (Figure 1), the company saw an opportunity to impact three goals with an “Everything as a Grid” approach:

- ■ Sustainability

- ■ Power reliability

- ■ Energy affordability

The local grid can be unreliable at this facility, which impacts production. At the same time, regional energy costs had trended up; during peak hours, the cost of energy could be four times the standard rate.

With energy storage and microgrid control, Eaton transformed the facility from an energy consumer to a “Plant as a Grid.” The site already had 200-kW solar generation in place. Eaton added its xStorage solution, which leverages second-life electric vehicle batteries. The company also incorporated its Power Conversion System (PCS) technology, which reduces the need to switch on the 400-kVA diesel generator set by automatically shifting loads and providing seamless transfer of power. Using Eaton uninterruptible power system (UPS) technologies, the innovative PCS solution can operate as an inverter or provide voltage reference for solar PV in the case of a utility outage.

This isn’t an isolated challenge. In Africa, The World Bank Group Enterprise Surveys estimate that manufacturing firms are losing anywhere from 6% to 20% of sales revenue due to power outages. As demonstrated at the Wadeville facility, applying a “Plant as a Grid” approach can significantly improve productivity and profits.

What’s the result? The Wadeville facility shows what “Plant as a Grid” can do, which includes:

- ■ Avoid outages and reduce the risk of production losses.

- ■ Offset energy costs through solar PV and energy storage that relieve pressure on the regional electricity grid.

- ■ Support peak shaving, which reduces maximum demand charges.

- ■ Enable energy arbitrage, which reduces energy consumption from the utility when costs are highest.

In less than a year, this “Plant as a Grid” approach helped the facility maintain uptime, and is also helping reduce the production facility’s monthly utility bill by 30%. Additionally, improved manufacturing plant uptime and reductions in diesel-fuel consumption have resulted in operational savings of 56%.

Originally, the payback period was estimated to be about five years, including the cost of replacing the energy storage system. However, due to the increase in load shedding in South Africa, this payback period has decreased significantly.

Further, the “Plant as a Grid” approach to powering the plant is lowering environmental impact by saving 11,812 metric tons of carbon dioxide. Efficient energy use is especially important for commercial and industrial organizations.

From the outset of the project, Eaton’s regional team ensured that the Wadeville microgrid project would serve as a learning laboratory for South Africa. The project shares data to increase knowledge of microgrid technology, and shares the business case for microgrid development, using this project as a case study. Discussions about the project have taken place with hundreds of individuals, including delegations from commercial and industrial equipment manufacturers who are facing similar challenges to the ones Eaton addressed at the Wadeville plant.

Energy Storage, Microgrid Control Help Meet Energy Goals

The energy transition is driving a model where “Everything as a Grid” capability will become essential to communities and businesses around the world. Energy storage is critical to this model, and it’s no surprise that analysts expect the installed base of energy storage to increase 13 times in the next decade, according to BloombergNEF’s New Energy Outlook 2019.

Energy storage and microgrid controls give organizations the ability to consume all the energy produced locally via DERs, and have that power available exactly when it’s needed. This technology has the ability to scale, and the flexibility to integrate into existing energy infrastructure as energy needs evolve and existing infrastructure is modernized.

|

|

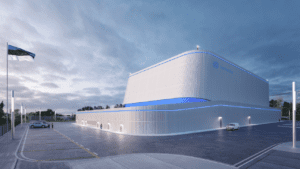

2. Eaton’s Energy Aware UPS solution uses Eaton’s reserve Uninterruptible Power Supplies (UPS) to enable organizations, including commercial and industrial facilities, to seamlessly support grid stability while still powering critical applications. Courtesy: Eaton |

In addition, innovations in energy storage systems are infusing new capabilities into existing energy assets, creating far more effective power systems. For example, uninterruptable power supplies (UPS) have been around for a long time, and they provide essential backup power functionality for critical power systems. Yet, they’re unused much of the time. Eaton developed an intelligent control system that’s enabling customers to put their energy to work in new ways. This EnergyAware (Figure 2) and GridAware UPS technology enables data centers and critical facilities, for example, to monetize underused assets, gain new revenue, cut energy bills, and improve sustainability, all while continuing to provide vital emergency power functions.

Beyond the ability to store energy, commercial and industrial organizations are optimizing where, when, and how power is used by dynamically controlling DER assets through microgrid controls. Energy resiliency and efficiency are key drivers to use microgrid technology in commercial and industrial applications. Knowing that your electricity supply is going to be on, no matter if there’s a storm, outage, or other event is essential as our world becomes more electrified. We’re seeing commercial and industrial customers investing in energy resiliency and applying microgrid systems to achieve it all around the world.

The Possibilities of ‘Everything as a Grid’

Taking an “Everything as a Grid” approach puts the power into the hands of the business. Even if a business is not ready to add large-scale renewables and storage to its energy mix, it can start modernizing systems and utilizing existing assets to create a more connected, dynamic, and controllable power system to support the enterprise’s unique resiliency and sustainability goals.

The opportunity is to change how energy is used and give businesses powerful advantages. And it’s delivering on energy resiliency, cutting costs, creating new revenue streams, and supporting a far more sustainable world. The benefits are many:

- ■ Gain new revenue—Participate in utility frequency response programs.

- ■ Reduce energy costs and lower utility bills—Shrink demand charges with time-of-use optimization that supplements power loads during peak times.

- ■ Improve sustainability—Support grid demand response and other ancillary services while reducing generator usage.

- ■ Maintain power reliability—Protect critical loads with programmable minimum runtime and load levels.

- ■ Support grid stability—Dynamically balance the grid with fast energy assets.

The “Everything as a Grid” approach can transform the future of a business, and commercial and industrial enterprises have the opportunity to experience that transformation. ■

—John Vernacchia is segment manager-renewable solutions for Eaton’s electrical business.