Air Casters Speed Equipment Moves

When it comes to moving megaton items like feedwater heaters or recirculating pumps, conventional moving tools such as wheel rollers, cranes, hoists, and come-alongs may be virtually useless. In some cases, moving large components is dangerous in a space-constrained location surrounded by delicate process control equipment.

Feedwater heater and recirculating pump removal and replacement are two situations in which nuclear plant operators have used AeroGo for moving equipment weighing up to 5,000 tons on an invisible cushion of air (Figure 5).

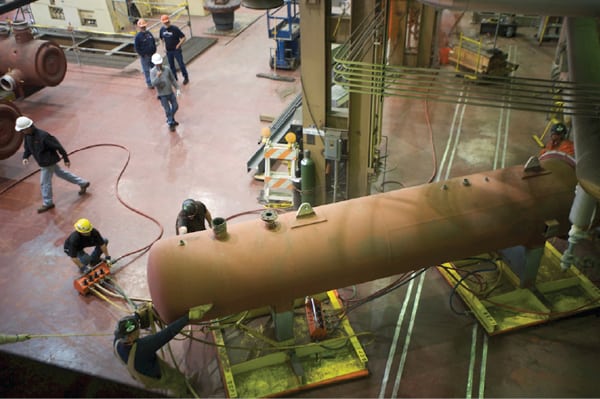

5. Air suspension ride. Recent removal and replacement of a reactor recirculating pump was facilitated by a custom-designed air cushion system. Only two technicians were required to guide the 50,000-pound system through the plant. Courtesy: AeroGo

Recently, a reactor recirculating pump was replaced at a nuclear plant located on the eastern seaboard. The pump was first removed vertically from a well in the reactor chamber, turned on its side, set on rails, and then pulled onto a cart. The whole load then had to be backed up and pivoted to align with an egress hall, a passageway lined with hydraulic control systems for the nuclear reactor core rods. There was no room for mistakes. Even paint scrapes were considered part of the radiation hazard potential.

AeroGo created a drivable cart mounted on air casters that allowed the 50,000-pound pump to transit through twists and turns of the passageway to an outside area where it could be loaded onto a truck. Estimated clearance was an optimistic 1 to 2 inches. Only two drivers, each controlling a compressed air–powered traction device located at opposite ends, moved the cart. The cart’s mating fixtures were engineered to flex in order to mate precisely with the giant pump, aided by Acme screws at each corner to allow tiny, incremental adjustments for a perfect fit.

Of course, when recirculating pumps are removed, there must be a replacement. The company moved the new pump in with equal ease using the same air caster transport system—but this time with a crew from a second shift that had not received prior training in using the system. AeroGo technicians trained them on the spot in less than 20 minutes, and the move was flawless.

—Contributed by AeroGo.