Ideal for Pollution Control & Monitoring Systems’ Stack or Flue NOx Scrubbers

San Marcos, CA—November 6, 2025—Process and pollution control engineers will find that the FCI ST100A Flow Meter helps them more accurately control the application of ammonia (NH3) for nitrous oxide (NOx) removal under harsh operating conditions in large flue stacks at cleaner coal electric power plants, which helps these plants meet environmental regulations that reduce greenhouse gases and helps protect the planet from global warming.

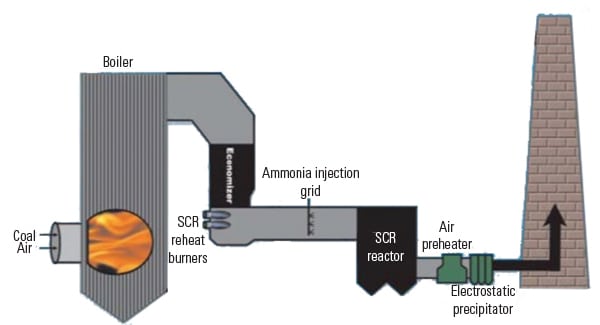

This proven thermal dispersion technology air/gas flow meter allows electric power generation plant operating teams to optimize the performance of selective catalytic reduction (SCR) systems. The rugged ST100A Flow Meter provides them with a highly repeatable gas measurement solution to control vaporized NH3 in such applications. While enhancing system performance, this instrument also reduces NH3 consumption and costs. It is suitable for use in ammonia production plants and fertilizer plants as well.

Electric power plant engineers troubleshooting problems with the inconsistent measurement of vaporized NH3 injected into their flue gas as a means to reduce NOx emissions will find the ST100A Flow Meter offers them a much more accurate and dependable measurement solution. Some pollution control systems have utilized volumetric flow sensors, which weren’t well-suited for controlling the NH3 gas injection system. Switching to an air/gas direct mass flow sensing ST100A Flow Meter, as opposed to volumetric measurement, solves these false readings issues.

With a standard wide flow turndown ratio of 100:1 (up to 1000:1 based on the application), the ST100A Flow Meter provides simple direct mass flow gas measurement over a wide flow range. These insertion-style thermal flow meters are typically installed for clean coal electric power applications on the primary vaporized ammonia feed lines to the nozzle grid, and then the in-line style ST100AL Flow Meters are also installed at each of the nozzle locations.

This precision thermal flow meter can be factory-calibrated to measure virtually any popular gas as well as mixed gases. The technology is suitable for use in wet and dirty gas applications, having no small ports prone to fouling. The basic insertion style air/gas meter features a thermal flow sensing element that measures flow from 0.25 up to 1,000 SFPS (0.07 NMPS to 305 NMPS) with accuracy of ±0.75 percent of reading, ±0.5 percent of full scale. The basic in-line style meter is available for 2-inch and smaller line sizes (Figure 1).

The transmitter designed for the ST100A Flow Meter is unmatched in meeting both a plant’s current and future needs for outputs, process information, and communications. If the required output is traditional 4-20 mA analog, frequency/pulse, or advanced digital bus communications such as HART, Modbus, PROFIBUS, or FOUNDATION Fieldbus, the ST100A Flow Meter will meet all major instrument integration needs. Its advanced bus communications are all third-party certified and registered, so users never have to worry about them.

Featuring an easy-to-read graphical, multivariable backlit LCD display, the ST100A Flow Meter brings new meaning to the term “process information.” Its sophisticated readout continuously displays all process measurements and instrument status for easy on-site viewing by technicians, and it has the ability to query for service diagnostics via an integral, optical HMI that does not require declassification of hazardous areas.

Manufactured for extreme industrial process and plant conditions, the ST100A Meter can be installed for service up to 850F (454C). Users can choose from either integral or remote (up to 1,000 feet [300 meters]) electronics versions. The ST100A Meter is agency approved for hazardous environments, including the entire instrument, the transmitter, and the rugged, NEMA 4X/IP67 rated enclosure.

Global approvals include: ATEX, CPA, CRN, EAC/TRU CU, FM, FMc, FDT, GOST, IECEx, Inmetro, and NEPSI. Third-party failure rate data per IEC 61508 is available that demonstrates the suitability of the hardware architecture for SIL 1 (HFT=0) applications.

A DwyerOmega brand, FCI delivers precise flow and level instrument measurement solutions using advanced thermal dispersion technologies. With more than 60 years of experience and the world’s largest installed base of thermal flow meters, flow switches, and level switches, FCI is the trusted expert in flow and level instrumentation.