For many years, the OEM fix for major cracking or shell distortion was replacement of the defective shell, also referred to as casing by some OEMs, with new. Mechanical Dynamics…

For many years, the OEM fix for major cracking or shell distortion was replacement of the defective shell, also referred to as casing by some OEMs, with new. Mechanical Dynamics…

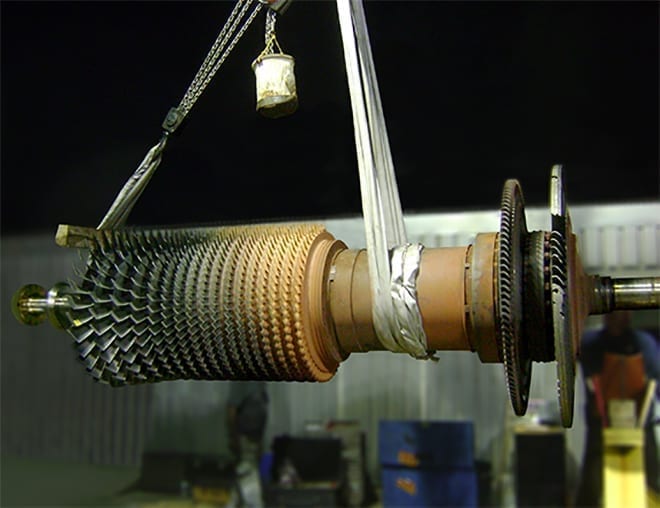

Mechanical Dynamics & Analysis (MD&A) recently completed generator field rewind with a rotor slot dovetail repair on a customer’s GE® 650,000 KVA generator field. The work scope was performed at the customer’s…

MD&A’s Steam Path Audit webinar describes the technical process of conducting a visual inspection of a steam turbine’s steam path for the purpose of identifying and quantifying deficiencies in thermal […]

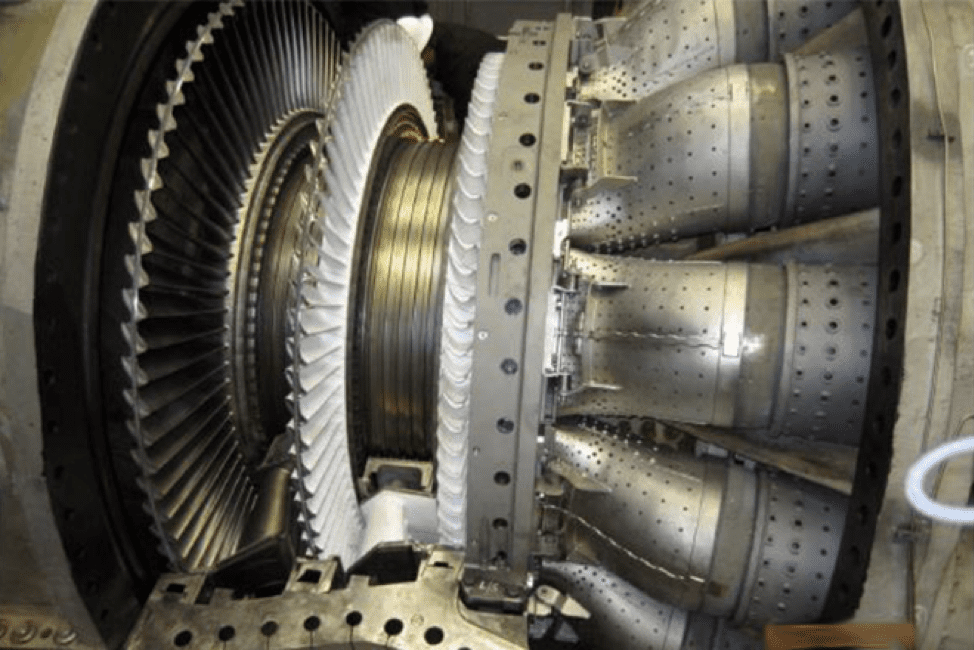

In this webinar we will cover the typical limiting factors of gas turbine components and how they can be repaired. We will cover the steps used in implementing a life time extension and will show some case studies. Some examples of how new parts are redesigned with features that make them more robust will also be covered. This webinar will be beneficial to the engineers and power plant personnel involved with the refurbishment and replacement of the gas turbine hot gas path components.

Elevated temperatures take a big toll on gas turbine components risking cracks, corrosion, wall thickness, and material condition. Repair enhancements can extend a part’s life by slowing its degradation and…

A carefully orchestrated process was set in motion when Mechanical Dynamics & Analysis (MD&A) ventured to complete a 7FA gas turbine hot gas path inspection, together with a 7FH2 generator…

Competitive maintenance uses an analytical process and condition-monitoring tools to select the optimum maintenance strategy for each plant system. For example, the optimum strategy for the plant’s steam turbine will…

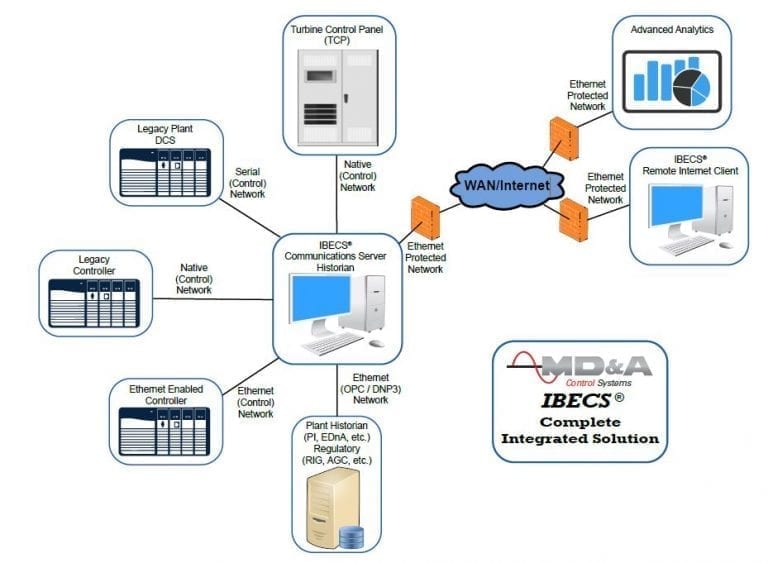

Power plant control and monitoring can be complex given the need to integrate many different platforms. Adding to the complexity is the fact that HMI’s (Human-Machine Interface) supplied by the…

Mechanical Dynamics and Analysis (MD&A) was contracted after a forced outage to perform a major overhaul on a cogeneration unit’s MS5001PA gas turbine, and to remove, test and inspect the…

Mechanical Dynamics and Analysis (MD&A) was retained by a utility to perform a stub-shaft repair of a generator rotor collector-end shaft. The customer reported that the generator rotor had suffered a collector…