When I was a kid, I used to watch thunderstorms roll in from the porch, tracing lightning across the sky and marveling at how energy moved between clouds. We build infrastructures now that try to do the same thing—collect, store, and dispatch power on demand. But as energy storage scales (Figure 1), it’s not the lightning we should fear. It’s the battery.

COMMENTARY

Over the past year, we’ve seen startling reminders of what happens when energy storage systems fail. In South Korea, a lithium-ion battery fire knocked government services offline. In Singapore, a data center lost emergency backup power in an instant. In California, residents were evacuated as smoke from a major lithium-ion installation darkened the sky. These aren’t hypothetical risks. They are real events with real consequences.

Energy storage is essential for decarbonization, grid resilience, and clean power integration. But the public debate around batteries often misses a critical nuance: different chemistries behave differently under stress. We tend to treat “battery” as a single technology, which is a mistake.

Lithium-ion remains dominant for good reason. It has high energy density, declining costs, and decades of deployment experience. But it also carries a known failure path called thermal runaway. When a cell overheats or is damaged, it can cascade to neighboring cells in a self-amplifying reaction. That reaction releases heat, gas, and pressure, and can reignite even after suppression. The codes and testing standards we rely on, including UL 9540A and NFPA 855, are important. But they are tools to manage danger, not remove it.

Flow batteries, including vanadium-based designs, operate differently. They use non-flammable, water-based electrolytes. The energy is stored in external tanks and circulated only when needed. There is no dense mass of reactive cells waiting to ignite. When the system is idle, the reaction is idle. There is no path to runaway. That change—from managing risk to choosing a chemistry without that risk—represents real progress in energy storage safety.

We are at a turning point. We can continue layering safety procedures on top of reactive materials, or we can adopt technologies that are inherently stable. The second path is not marketing. It is engineering maturity.

For data centers, where uptime cannot be compromised, a battery system that will not burn even under extreme conditions should be the standard. For municipalities and neighborhoods near battery sites, a non-combustible system creates a completely different conversation. It removes fear from the equation and replaces it with trust.

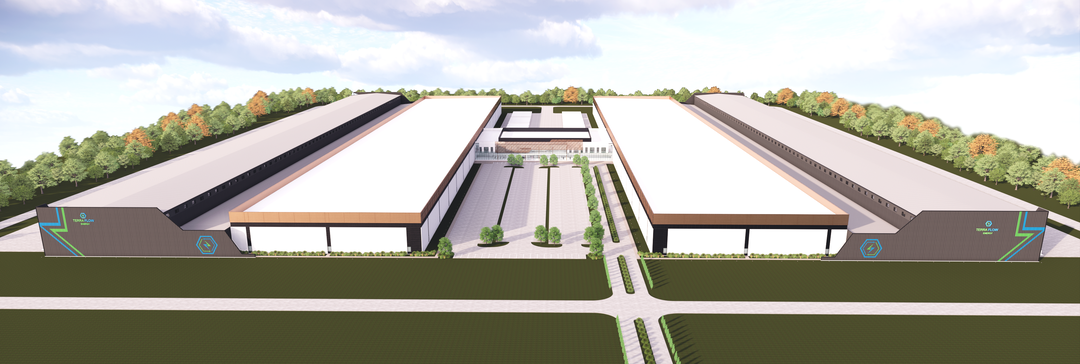

Flow and long-duration batteries have tradeoffs. They require more space and fluid management (Figure 2), but they also remove the need for complex fire suppression and high-cost containment systems. When those factors are included, the cost gap narrows quickly. What remains is the peace of mind that the system designed to protect the grid will not endanger the community it serves.

The cost of caution is rising, and so is the demand for reliability. The real question is not whether lithium-ion can be made safer. It is why we keep using something that will never be as safe as what could replace it.

Communities deserve storage that strengthens resilience without creating new risks. Developers deserve technology that meets both safety codes and public confidence. And operators deserve systems that deliver reliability without compromise.

Safety by design is not a slogan. It is the next step in how we build energy storage for a world that depends on it.

—Amanda Simonian is the Chief Marketing Officer of TerraFlow Energy, a Texas-based developer of long-duration storage infrastructure designed to strengthen grid reliability and support the growing demands of artificial intelligence (AI)-driven data centers.