Focus on O&M

-

O&M

Best Management Practices for Coal Ash Ponds

The unfortunate coal ash spill at the Tennessee Valley Authority’s (TVA’s) Kingston Fossil Plant that occurred on December 22 has heightened national awareness of the problems associated with utilities’ coal ash surface impoundments if they are not properly maintained.

-

O&M

Reduce Costs with Wireless Instrumentation

New wireless technologies for power plant instrumentation offer significant cost savings when compared to traditional wired networks. The value of this cost savings is especially relevant in the highly competitive power industry, where aging facilities are common and upgrades are an expensive necessity. Modern wireless networks offer a reliable upgrade path that even provides some unexpected benefits when compared to traditional copper networks.

-

O&M

FERC Focuses on Internal Compliance Programs

By now, most electric industry participants are aware of the mandatory reliability standards required by the Energy Policy Act of 2005 and managed by the North American Electric Reliability Corp. (NERC). Bulk-power system users, owners, and operators (known as NERC registered entities) are responsible for complying with the set of standards that are applicable to their operations in their specific region. Compliance is monitored by the NERC regions (Texas Regional Entity, Western Electric Coordinating Council, Reliability First Corp., Midwest Reliability Organization, SERC Reliability Corp., Florida Reliability Coordinating Council, Northeast Power Coordinating Council, and Southwest Power Pool) through spot checks, self-certifications, audits, and investigations.

-

O&M

Preventing Boiler Code Violations Creates a Safer Work Environment

Nearly 10% of boilers and pressure vessels inspected in the second quarter of 2008 were slapped with violations, which means that the violations put workers and equipment in danger, according to a quarterly report released by the National Board of Boiler and Pressure Vessel Inspectors.

-

O&M

Converting a Pump to Use Mechanical Seals

Wear and leakage are common maintenance problems that result in pump discharge pressure dropping below optimum levels and reduced pump efficiency. Converting pumps to mechanical seals eliminates fretting or grooving of the shaft and provides for easier pump maintenance. By converting to mechanical seals, a plant also avoids incurring expenses associated with the replacement of sleeves and shafts.

-

Business

Training the Next Generation of Welders

Concern about the shortage of skilled workers for the energy industry has grown considerably over the past few years. Most discussions have focused on the shortage of engineers, but recently concerns about the scarcity of technical crafts have arisen as well.

-

O&M

Stopping Natural Gas Leaks

Chances are you have endured the tedious process of removing fuel piping when maintaining just about any gas turbine, especially aero-derivative engines that are usually swapped out rather than repaired in place. One of the most time-consuming jobs after reassembling the fuel piping is checking for leaks at all the flanges. In a large frame-size turbine, that means sealing up to 64 flanges and then removing the seals after the leak testing.

-

O&M

Improving Workforce Connectivity

Wright-Hennepin Cooperative Electric Association (WHCEA) is an electric distribution utility located in Rockford, Minn., that has been serving Wright County and western Hennepin County near Minneapolis with electricity since 1937. WHCEA is a not-for-profit, member-owned energy and service cooperative dedicated to enhancing the quality of life of its members and providing reliable services. Its field operations department consists of 35 fleet members who focus on building and maintaining electric power lines.

-

O&M

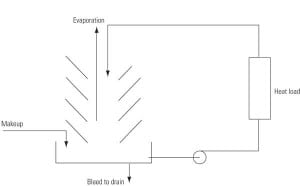

Conserve Water by Improving Cooling Tower Efficiency

Though an abundant supply of freshwater has been taken for granted in many parts of the world, its availability is becoming less certain, even in North America. Water is a valuable resource and commodity that needs to be efficiently managed to minimize waste, reduce energy consumption, and control cost, especially for power generation. The industry must respond by seeking out more efficient ways to use water, such as by implementing water recycling and reuse strategies, especially for critical equipment like cooling towers.

-

O&M

Oregon wind turbine loses its bearings

The generator bearings on a wind turbine located in Oregon (Figure 1) first failed in May 2006, only 11 months after the tower was brought on-line. The company that owns and operates the wind farm replaced the bearings and slip rings, but the new bearings failed only five months later. Once again, new bearings and […]