Focus on O&M

-

O&M

Rebuilding Feedwater Heaters While a Plant Is Online

Rebuilding aged feedwater heaters can make better economic sense than buying new ones, because rebuilding reduces capital cost and plant outage expenses. At one Texas generating station, rebuilding saved one-third the cost of a new feedwater heater while improving the plant’s heat rate.

-

O&M

Halar-Lined Chimney Remains Maintenance-Free

A fiberglass-reinforced plastic (FRP) Halar stack liner was installed at Vattenfall’s 300-MW Unit 2 at the Nordjylland Power Station in 1995. The 112-meter-high (367-ft) stack, protected from corrosion by the ECTFE liner, is still in excellent condition and has not required any repairs during more than 13 years of service. (ECTFE is short for ethylene chlorotrifluoroethlyene polymer, marketed under the brand name Halar ECTFE [Halar] by Solvay Solexis.)

-

O&M

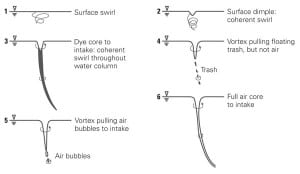

Scale Model Testing Confirms Adequate Refueling Water Storage Tank Vortex Allowance

Recent Nuclear Regulatory Commission (NRC) Component Design Bases Inspection activities have scrutinized empirical approaches used to determine vortex allowances for emergency core cooling system (ECCS) suction sources.

-

O&M

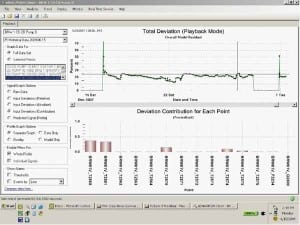

Catching Faults with Centralized Condition Monitoring

In 2007, Exelon Corp. began the Centralized Performance Monitoring (CPM) pilot program. The goal was to reduce downtime costs and lost revenue associated with the 25% of unplanned forced losses across its fleet of 17 nuclear power units without additionally taxing existing personnel or adding new personnel.

-

O&M

HDPE Replaces Carbon Steel in Safety-Related Pipe System

Corrosion of steel water pipes in the safety-related piping systems of aging U.S. nuclear power plants is fast becoming a safety concern and a significant operational cost, not to mention an indication of potential future liability for nuclear utilities currently constructing new plants or retrofitting existing sites.

-

O&M

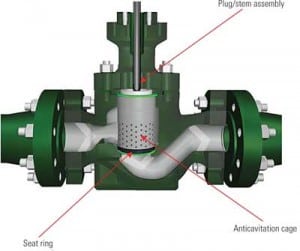

Ensure Your Valve Replacement Parts Meet OEM Specs

When high-temperature boiler feedwater passes through a control valve, the pressure drop can exceed several thousand pounds per square inch, placing extreme stress on the valve body and internal parts. If those parts are not engineered and manufactured to the highest industry standards, there is a very real possibility of the severe conditions damaging or destroying the valve.

-

O&M

Proper Valve Selection Reduces Downtime, Increases Process Efficiency

Many customer quotation requests provide only the line size, pressure class rating, and valve type. A typical request might read: size 4, Class 900 globe valve. Though this may be enough information to produce a valve quote, it rarely is enough information to size the best valve from both a performance and cost perspective.

-

O&M

Avoid These 10 Mistakes When Selecting Your New Water Treatment System

There are a number of reasons why your plant might be looking at new water pretreatment equipment in the near future. One common reason is the addition of new generating capacity. Regardless of the type of new generation, you can be sure that it will require additional high-purity water for processes ranging from direct steam generation to power augmentation, NOx control, and washing the blades of the combustion turbines.

-

O&M

Accurate Online Silica Analyzers Ensure Boiler Performance, Add Boiler Life

One key area at the 800-MW Michoud power station where O&M excellence is evident is in maintaining plant water quality.

-

O&M

The 7,000-Foot Challenge

The Springerville Generating Station in Springerville, Ariz. (Unit 3 was POWER’s 2006 Plant of the Year), uses two lined ponds to hold water collected from its cooling towers. With the construction of Unit 4, the plant’s owner, Salt River Project (SRP), one of Arizona’s largest utilities, wanted to increase the capacity of pumps used to move effluent from one pond to another to avoid the possibility of overflow. SRP engineers wondered if using a vertical turbine pump on a floating barge would improve managing the water levels in the two ponds.