Features

-

Synfuel

Biofuels help green up gas turbines

Ethanol and biodiesel have become mainstream fuels that are increasingly used in combination with gasoline or petroleum diesel in automobiles. Now these same versatile fuels are starting to be used to power gas turbines. LPP Combustion LLC has developed a fuel preparation and delivery system that converts liquid fuels such as No. 2 fuel oil, biodiesel, ethanol, and coal liquids into substitute natural gas, which existing natural gas hardware can burn while enjoying reduced emission rates similar to those of natural gas.

-

O&M

Boiler optimization increases fuel flexibility

Burning spot market fuels can reduce plant fuel costs, but it can also introduce unexpected operational problems throughout the boiler island. Orlando Utilities Commission’s Stanton Energy Center optimized its Unit 2 combustion system and improved O&M practices as part of a project to increase the unit’s fuel flexibility without degrading reliability or heat rate. OUC’s attitude: If you can measure it, you can manage it.

-

Instrumentation & Controls

Making PM systems sweat the small stuff

Modern predictive maintenance systems can monitor the health of most plant equipment. By sorting through the wealth of information those systems deliver, operators can discern important trends, including the early signs of a system or component failure.

-

Smart Grid

Boulder to be first “Smart Grid City”

The next-generation power grid—enhanced by digital technologies throughout the network to give generators, distributors, and customers greater control—promises to improve efficiency and lower operating costs. This year, in the most full-scale effort yet, Xcel Energy begins introducing intelligent grid technologies that it hopes will make Boulder, Colo., the first Smart Grid City.

-

Hydro

A new wave: Ocean power

The idea of harnessing the vast power of Earth’s oceans has tantalized humans for more than a century. Today, the prospect of generating as much as 4,000 TW of clean energy from marine sources is fueling a resurgence of interest in a variety of technologies.

-

Coal

Future of national mercury rule now uncertain

This February, a federal appeals court tossed out the Clean Air Mercury Rule and its cap-and-trade program and ordered that mercury be regulated more stringently as a hazardous air pollutant. Adding insult to injury, the court made its ruling effective one month later. While the EPA regroups, state energy and environmental regulators will have an opportunity to look closely at recent power plant permits for guidance. This article reviews the technology options and regulatory approach for mercury control used on recently permitted and currently operating coal-fired plants.

-

Instrumentation & Controls

Cation conductivity monitoring: A reality check

The ability to detect contaminated feedwater or steam before it can corrode the internals of a turbine or HRSG and cause a forced outage is worth millions. One knock against cation conductivity monitoring—still the most common technique for the early detection of contamination—is the difficulty of interpreting conductivity readings when the plant’s makeup contains significant levels of organics or CO2. Here are the pros and cons of cation conductivity monitoriting and some alternative monitoring methods.

-

Coal

New coal plant technologies will demand more water

Population shifts, growing electricity demand, and greater competition for water resources have heightened interest in the link between energy and water. The U.S. Energy Information Administration projects a 22% increase in U.S. installed generating capacity by 2030. Of the 259 GW of new capacity expected to have come on-line by then, more than 192 GW will be thermoelectric and thus require some water for cooling. Our challenge will become balancing people’s needs for power and for water.

-

Nuclear

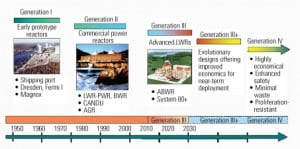

Developing the next generation of reactors

Dozens of intrinsically safe Generation III+ reactors are expected to be deployed in the U.S. in the coming years. Today, scientists already are looking over the horizon to Generation IV reactors that will be capable of producing hydrogen and process heat as well as electricity while generating much less radioactive waste.

-

Instrumentation & Controls

Turbine technology maturity: A shifting paradigm

Selecting the right turbine(s) for a specific power project is a complex process that poses two challenges. One is understanding which field experience cited by suppliers represents proven technology; the other is evaluating whether a turbine upgrade represents an evolutionary change or a revolutionary transformation that warrants further study before deploying it in the field. Here‘s how a leading EPC contractor makes technology-neutral equipment selection decisions on behalf of its customers.