COAL POWER Direct

-

Coal

Speaking of Coal Power: IGCC Sticker Shock

Former Illinois Senator Everett Dirksen once observed, "A billion here and a billion there, and pretty soon you’re talking real money." The same can be said about skyrocketing estimated costs of integrated gasification combined-cycle (IGCC) plants as their designs are fleshed out. The higher price tags shouldn’t be a surprise — the more you learn […]

-

O&M

PRB Tech Notes: Lawrence Energy Center Showcases Winning Plant

Lawrence Energy Center (LEC) proudly hosted about 60 representatives of the Powder River Basin Coal Users’ Group (PRBCUG) at its July 24th open house, luncheon, and plant tour. LEC was named the PRBCUG’s 2007 Plant of the Year at this year’s ELECTRIC POWER Conference and Exhibition in Chicago, May 1 – 3. Traditionally, the winning […]

-

O&M

Coal Plant O&M: Smart Sootblower Tailors Cleaning to Need for It / Blending’s Impact on Coal Quality

The 1990 amendments to the Clean Air Act require coal-fired power plants to reduce their emissions of the pollutant SO2. To do so, many have switched to, or are considering switching to, Powder River Basin (PRB) coal. Unfortunately, PRB coal has a tendency to leave excessive and tenacious deposits on boiler heat-exchange surfaces. Complicating the problem, the distribution of the deposits is far from uniform.

-

Coal

The Coal Patrol: Coal to Synfuels: Deal or No Deal?

Synfuels’ political bubble has burst in Washington, but the market may step in where Congress fears to tread. When coal industry interests, in the form of the CTL Coalition, got a bill with strong federal support for coal-to-liquids technology before the Senate this spring, it appeared that the political skids were greased for some kind […]

-

O&M

Lignite Drying: New Coal-Drying Technology Promises Higher Efficiency Plus Lower Costs and Emissions

The U.S. Department of Energy (DOE) and Great River Energy are testing a new coal-drying technology that could dramatically reduce the emissions of lignite-burning power plants. The project was selected for funding during Round I of the DOE’s Clean Coal Power Initiative (CCPI), a series of competitions to demonstrate a range of promising clean-coal technologies. […]

-

Coal

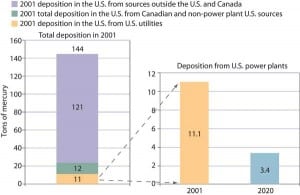

Mercury Control: Capturing Mercury in Wet Scrubbers: Part I

Are you using your flue gas desulfurization (FGD) system to its highest potential? You might not be if you’re not making it do double duty. It seems that million-dollar wet scrubber you installed to rid your flue gases of sulfur dioxide also can do a decent job of capturing mercury — under the right conditions. […]

-

O&M

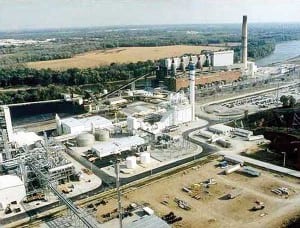

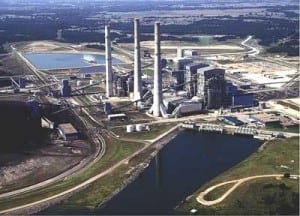

Pollution Control: LCRA Fayette Lowers NOx Below 0.10 lb/mmBtu

The Fayette Power Project (FPP, aka the Sam K. Seymour Power Station) is a three-unit, coal-fired generating plant sited near La Grange, Texas (Figure 1). Units 1 and 2, each with a nominal rating of 600 MW, are co-owned by the Lower Colorado River Authority (LCRA) and Austin Energy (AE). LCRA is a conservation and […]

-

O&M

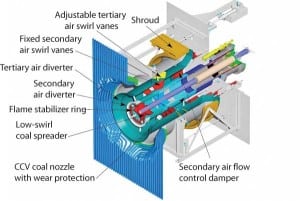

Pollution Control: Low-NOx Combustion Retrofit Options

Reducing NOx emissions from large utility coal-fired boilers has been a primary focus of the U.S. power generation industry since passage of the 1970 Clean Air Act and subsequent legislation. By the early 1990s, nearly all such boilers had installed some form of low-NOx burner (LNB) technology and/or overfire air (OFA) — the least expensive […]

-

Coal

The Coal Pile

Ninety years ago America was at war, and producers of coal (principally anthracite) were struggling to meet demand. It’s hard now to conceive of coal as the universal fuel, but there was a time when it was used in the U.S. to heat homes, schools, and libraries as well as to make steel and manufacture […]

-

Coal

Speaking of Coal Power: Illinois Coal Poised for Comeback

Sylvester Stallone, as Rocky Balboa, staged another magical comeback earlier this year — in the ring and at the box office. Just when you think Rocky is down and out for good, the sixth release of the Rocky franchise just may be the best of the lot. "Down but not out" is also an apt […]