For decades, fuel cell innovation has been guided by two main benchmarks: cost per kilowatt and stack durability. These remain important, especially in applications driven almost entirely by project economics.

However, in many of the sectors where fuel cells are poised to make the biggest impact—including aviation, long-haul mobility, and distributed energy—traditional metrics no longer tell the full story. Instead, power density is becoming the most critical factor in determining both technical and commercial viability.

COMMENTARY

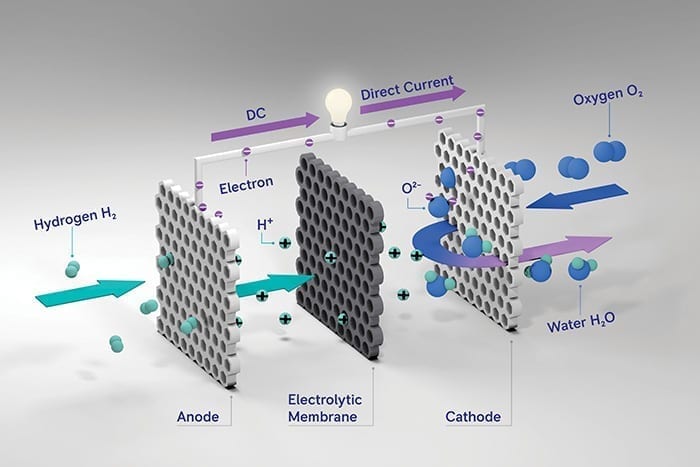

Power density refers to the amount of power a fuel cell stack can produce relative to its size or weight. The two primary measures, volumetric (kilowatts per liter) and gravimetric (kilowatts per kilogram), are more than just technical specifications. They represent the practical limits that determine whether a fuel cell system is viable for real-world use. In a light electric aircraft, increasing gravimetric power density by 25% could reduce system weight by several kilograms, enough to carry a larger payload or extend flight duration by 20 to 30 minutes. Even in containerized energy systems, improved volumetric density reduces enclosure size, simplifies cooling requirements, and lowers logistics costs. These aren’t just engineering improvements, they directly affect commercial outcomes.

Achieving this kind of power density isn’t about rearranging components or optimizing existing designs. It requires a new approach to materials and stack architecture. Traditional stacks built with graphite or coated metal bipolar plates face built-in constraints. These components are heavy, prone to corrosion, and limited in their ability to precisely control reactant flow, all of which affect performance, power density and durability.

Some developers are now turning to solar-grade silicon. Using mature fabrication processes from the solar and microelectronics industries, developers can create stacks with micron-scale flow fields, thinner components and more uniform reactant distribution. These stacks are lighter, more compact and more resistant to harsh operating environments.

Third-party testing is starting to confirm these advantages. In one recent evaluation by TÜV Rheinland, a silicon-based 150-kilowatt fuel cell stack achieved power densities of 9.8 kilowatts per liter and 9.7 kilowatts per kilogram. These results weren’t theoretical, they came from full-scale, production-ready systems designed for real-world applications.

Procurement teams are increasingly using power density as a first-round filter when evaluating fuel cell options. If a stack can’t meet a minimum density threshold, it may be excluded from consideration even before cost or durability are discussed. This is especially true in sectors where space and weight are primary constraints, such as aerospace and portable energy systems.

The bottom line is clear. As fuel cells move into more compact and mobile use cases, power density is no longer a secondary metric. It defines whether a system can fit, operate efficiently and deliver value. Developers who optimize for power density are better positioned to lead in emerging markets. Those who overlook it risk falling behind.

—Daniel Zafir is director, Business Development and Global Partnerships, at Siltrax.