Why Your Generation Portfolio Requires an Upgrade from Peakers to Balancers

A highly renewable grid requires flexible and dispatchable power generation technology to maintain reliability. Reciprocating internal combustion engines (RICE) are a mature, scalable, and cost-effective grid-balancing solution with physical capabilities perfectly suited to integrate high levels of renewables, reduce carbon emission, and maintain a reliable grid. Empirical evidence from ERCOT shows that RICE are used during many more hours and ramped more often than similarly sized aero derivative gas turbines (AEROs), demonstrating that RICE are a superior choice for both grid peaking and balancing needs.

Flexible dispatchable generators can quickly ramp to full power when needed and, equally important, immediately turn off when not needed. Conversely, inflexible generation includes nuclear, coal, natural gas boilers, and even combined cycles, all of which have long start-up, shut-down, minimum up and minimum down times. While these technologies are technically considered “dispatchable”, they cannot meet the flexibility needs of minute-by-minute intermittency. RICE power plants possess the following five elements of flexible dispatchability needed to balance variable energy resources:

- Start-up time: RICE power plants can start up and reach full load within two minutes, enabling them to come online sooner and solve load and generation imbalances on the system.

- Minimum run time: RICE power plants have no minimum run time constraints. They can cycle on and off multiple times per hour without having to run for a set period of time.

- Minimum down time: RICE power plants have no minimum down time. They can restart rapidly after a shutdown, allowing them to quickly respond to changes in load, renewable variability, and generation outages.

- Minimum operating level: RICE power plants have minimum operating levels as low as 10%, meaning they can efficiently adapt to unreliable outputs of solar and wind and help keep the grid stable even when electricity demand drops.

- Ramp rate: RICE power plants can ramp output to 100% in less than one minute, allowing generators to respond to minute-by-minute grid demands without accruing additional maintenance costs, resulting in cost savings over time.

While RICE can provide traditional “peaking” capacity, these flexibility attributes are the reasons why RICE power plants should be thought of as renewable “balancers” rather than simply a traditional “peaker.” They provide an affordable, highly reliable, highly dispatchable option for backup and integration services to maintain resource adequacy when renewables are not available.

RICE vs. AERO: Engines Top Turbines in Balancing the Grid

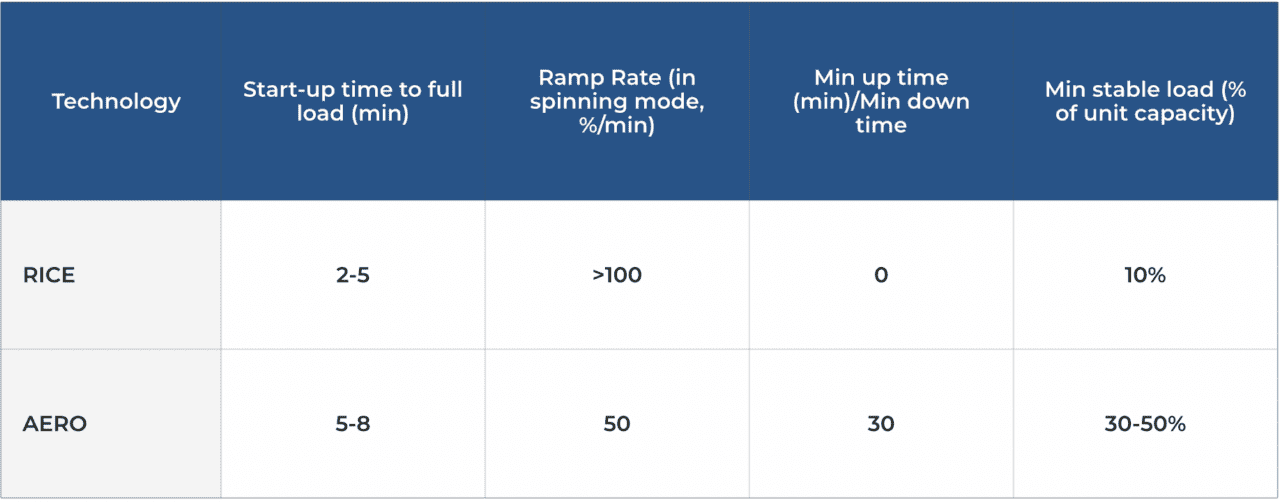

As utilities look to gas generation for reliability and to back-up renewables, two main candidates emerge: RICE and AEROs. AEROs are smaller gas turbines derived from jet engines that like RICE, can operate as renewable balancers, albeit not as flexibly as RICE. The following table compares the flexibility of AEROs versus RICE:

Table 1: RICE power plants possess more flexible, dispatchable attributes than AERO power plants.

The table shows that while both technologies are flexible relative to legacy thermal technologies, RICE has superior efficiency and flexibility. However, do the theoretical technical differences translate to improved performance in real life? We looked at the performance data in ERCOT to find out.

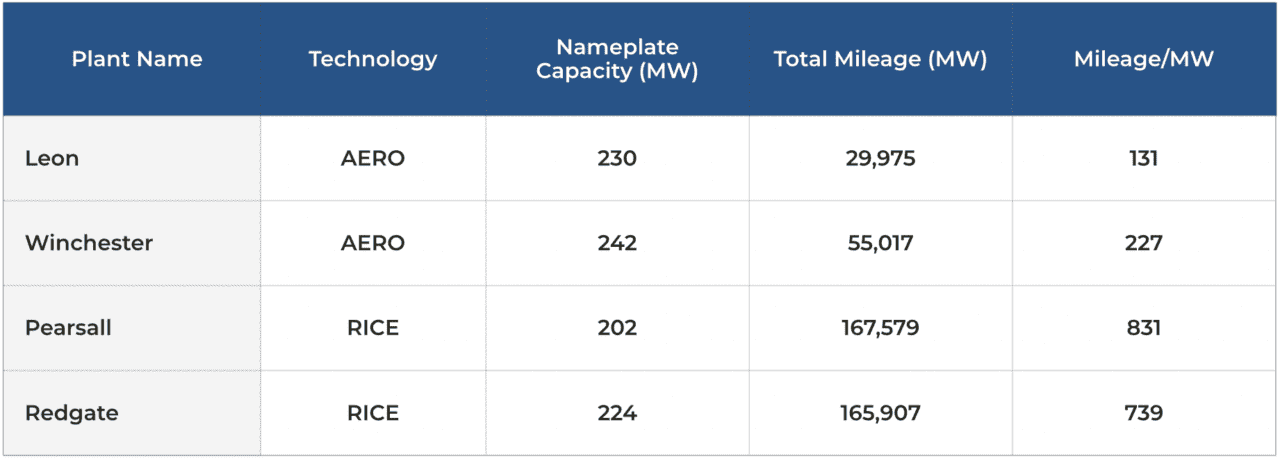

We analyzed dispatch data for four power plants in the ERCOT South Zone. Two power plants are RICE: Pearsall (202 MW) and Redgate (224 MW). The other two power plants are AEROs: Winchester Peaker Park (242 MW) and the Leon Creek Peaker (230 MW). We chose to compare these power plants because they are comparably sized and share similar power market pricing dynamics, including high price volatility as shown in Table 2 below.

Flexibility Means More Frequent Stops, Starts and Restarts, not just fast starts

RICE’s zero start-up cost and no minimum up or down time, combined with superior thermal efficiency, mean RICE’s ability to stop and start as dictated by 5-minute real-time prices is effectively unlimited. Table 2 shows that the RICE power plants start approximately three times more frequently than the AERO power plants.

Table 2: RICE power plants start and operate more frequently than AERO power plants despite similar pricing dynamics.

Next, let’s look at power plant mileage. Mileage is the sum of the ramps up and down. For example, an engine ramping from 8 MW to 18 MW and back down to 8 MW, would yield 20 MW of mileage. As intermittent renewables become more prevalent, grid operators will need to increasingly call on flexible resources to provide mileage to manage minutely fluctuations in supply and demand. Table 3 shows that the RICE power plants have three to six times the amount of mileage over the course of a year relative to AEROs. The RICE power plants achieve this because of their quick start-up times and ability to rapidly ramp output and operate efficiently at any operating level.

Table 3: RICE generate more mileage than AEROs due to faster ramp rates and lower minimum operating levels.

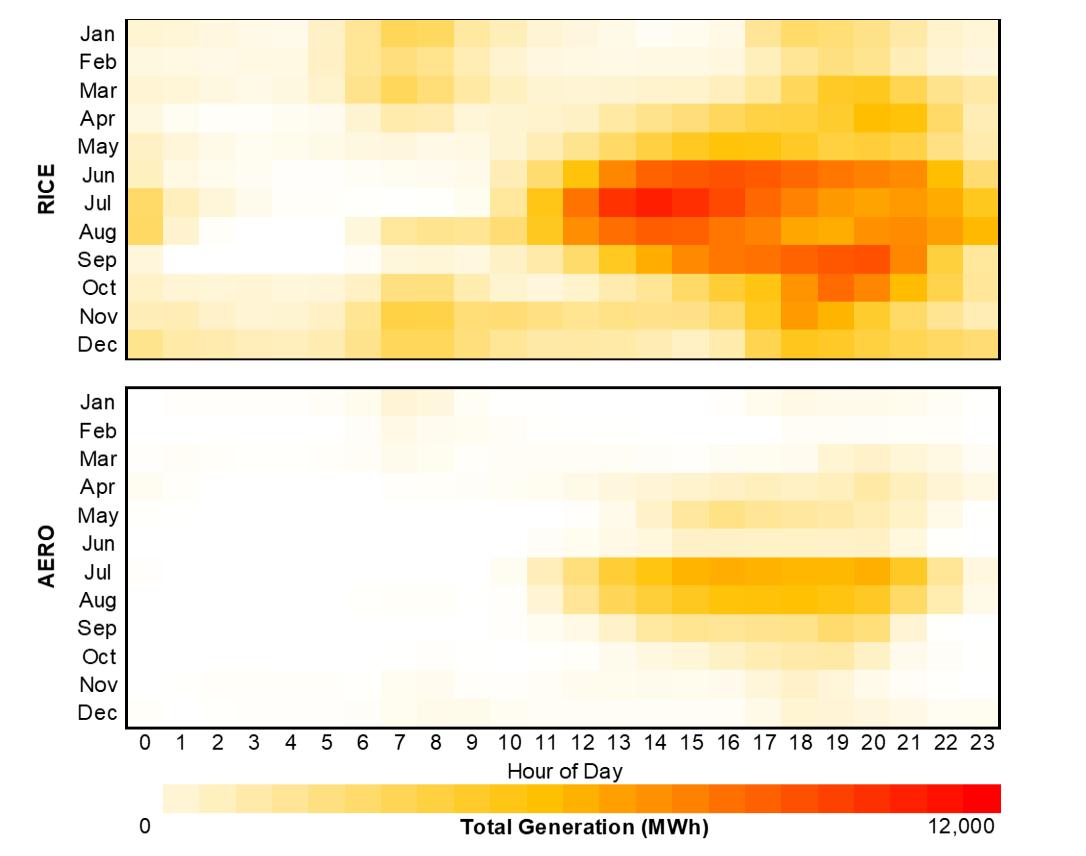

RICE Are Utilized All Year and All Hours While AEROs Are Used Only for Summer Peaking

Power generation dispatch data show very different operating behavior for RICE versus AEROs. The heat maps in Figure 1 show generation for the RICE and AERO power plants by month and hour. Red squares indicate more power generation. From these heat maps, we can see that the AEROs behave more like peaker plants; that is, the most megawatt hours are generated during afternoon and evening peaks in the summer with sparing operations during other times of the year. By contrast, while the RICE power plants demonstrate similar peaking behavior during the summer months, they also exhibit a much broader operating profile, with frequent generation across practically all hours of the day in each month. Put simply, RICE power plants offer peaking PLUS balancing capabilities.

Figure 1: RICE demonstrate both peaking and balancing capabilities, but AEROs are limited to peaking applications.

RICE Offers More Real-Time Market Value for Dispatchable Power

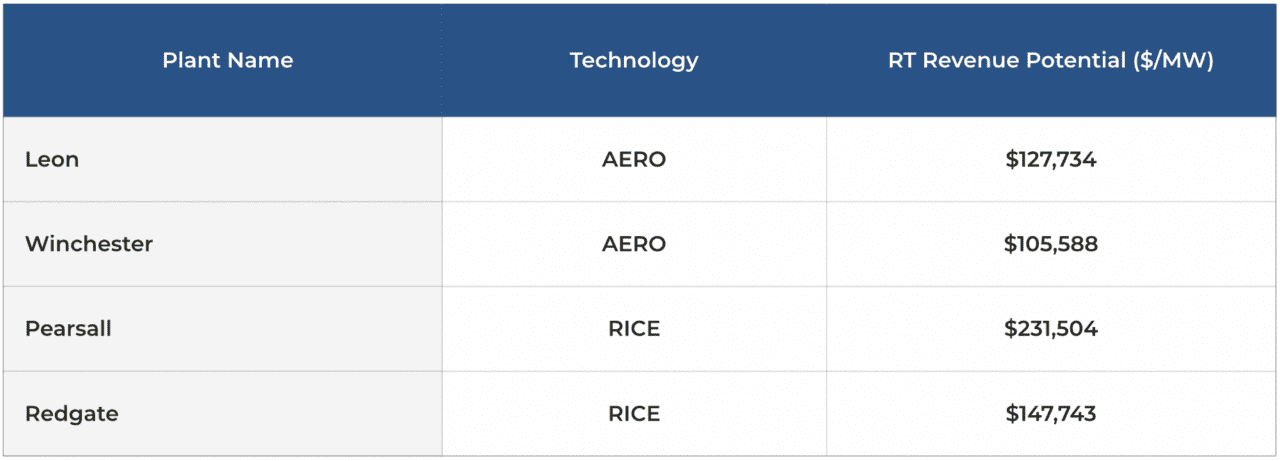

The flexibility value of RICE is best observed in dispatch to 5-minute real-time power prices versus hourly day-ahead market prices. Table 4 shows modeled real-time market revenue potential of RICE versus AEROs.

Table 4: Real-Time Revenue Potential for RICE vs. AERO Power Plants

When we overlay scheduled dispatch for the RICE and AERO power plants against real-time energy prices at their respective price nodes, our results suggest that RICE power plants can capture significantly greater value. For a 200 MW power plant, this translates into an additional benefit of approximately $4 to $24 million in value per year. The superior economic performance is explained by RICE’s higher thermal efficiency, lower start-up costs, and flexibility to catch short duration real-time price spikes.

The Future Grid Requires Flexibility

Renewables are being added at an unprecedented pace, and grid operators need the right tools to keep the lights on in any weather condition. Making the right resource choice for a rapidly changing grid requires a deep understanding of technologies and their specific capabilities as well as advanced modeling and analysis to ensure the correct investment. Given its superior flexibility and low operating costs, RICE is the right technology choice to enable a reliable and cost-effective electricity grid of the future.