The importance of RTO maintenance

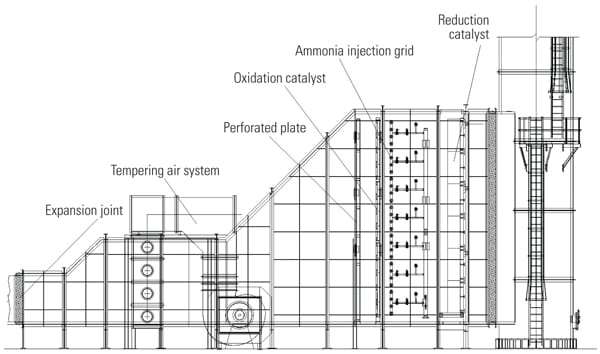

RTOs or Regenerative Thermal Oxidizers control emissions without producing harmful byproducts or hazardous waste. They help destroy volatile organic compounds (VOCs), hazardous air pollutants (HAPs) and other odorous emissions created during normal manufacturing and industrial processes by combusting them into carbon dioxide and water. RTOs pass hot exhaust gas and cooler inlet gas through one or more fixed heat exchanger beds containing ceramic media. This exhaust gas is usually produced by environments and processes that require ventilation, such as paint booths, food processing, plastic production and printing.

RTO technology is typically utilized for its process efficiency benefits, which results in low operating costs. In addition to their efficiency benefits, RTO systems reclaim liquid waste heat produced during the unit’s operation, allowing the system to sustain high temperature levels for longer periods of time—thereby eliminating the need for additional gas, bio-fuel or propane to power the process. Once the RTO unit reaches combustion temperature equilibrium, it processes fresh air and destroys VOCs and HAPs via thermal oxidation at 99 percent efficiency.

Because RTOs play such a vital role in production processes, employing proper maintenance practices is critical. Keeping an RTO system humming at optimal levels requires diligent system monitoring by qualified, experienced technicians. When left unobserved, common problems can include foreign particle accumulation that can foul heat-capturing stoneware beds and damage the network of valves – which are made up of a myriad of moving parts – that direct airflow. Being proactive to defend against these unforeseen hazards can save corporations hundreds of thousands (even millions) of dollars in lost production time and capital replacement costs. Preventive maintenance measures like scheduled service times and inspections can help companies avoid unexpected failures and costly downtime.

Case Study

Problem

An MPW Industrial Services client located in the Midwest was having a production line issue at its plant. The client used its RTO system to capture overspray (the application of any form of paint, varnish, stain or other non-water-soluble airborne particulate material onto an unintended location) in its automotive paint shop and sensors had detected an obstruction in the unit, causing a shutdown. The cost to rebuild the RTO was prohibitive and the company called in MPW for a solution.

Solution

MPW arrived, assessed and discovered particles had collected on the unit’s ceramic tiles, which restricted airflow. After consulting with the unit’s manufacturer, MPW devised a procedure utilizing low-pressure water blasting and a mild solvent to clean and refurbish the congested tiles while leaving the intricate and delicate RTO structure intact and unharmed. Work was completed during downtime and in just one weekend.

By creating a unique answer to a potentially costly problem, MPW saved the client more than $1.5 million.

As with most industrial operations, time is money—even a small glitch in the system can lead to catastrophic consequences. At MPW, our Facility Management Division has developed innovative methods to provide best-in-class cleaning and maintenance services to solve nearly any application issue.