Key Criteria that Drive Large-Scale Energy Storage Success

How a leading utility joined forces with a one-source EPC / O&M solutions partner

Amid growing demand for renewable energy sources, a Battery Energy Storage System (BESS) can elevate a utility’s fleet, stabilize the supply of electricity, reduce costs, and optimize revenue.

In the best-case scenario, a utility adds a BESS as a new asset, and then enjoys the near-term benefits of integrated resource expansion along with the longer-term benefits of revenue-generating, reliable, and dispatchable energy. Still, missteps can turn a promising project from asset to detriment. To arrive at the best-case scenario, partnership is key.

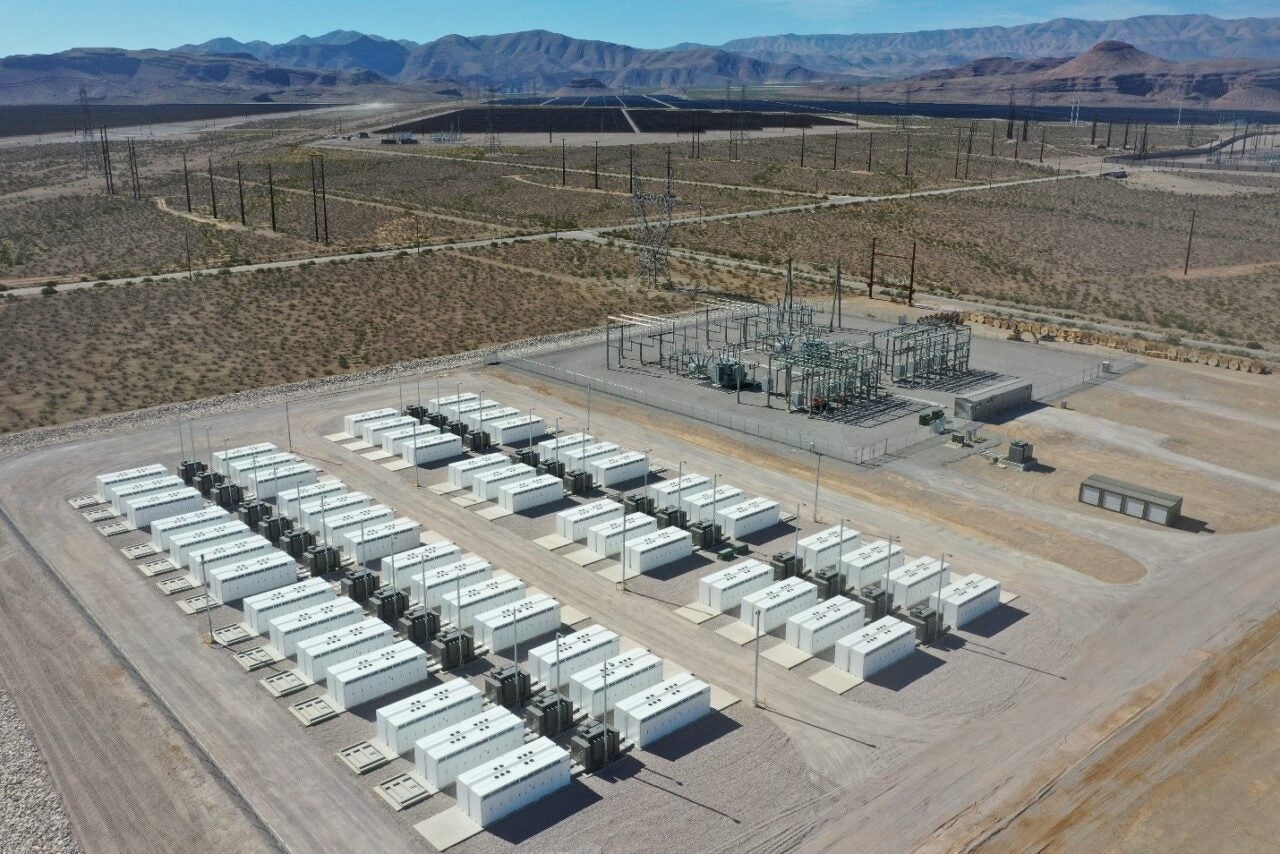

Case in point – Tucson Electric Power (TEP) is on track to begin operating a new BESS with 200 megawatts (MW) of capacity that will store 800 megawatt hours (MWh) of energy. The Roadrunner Reserve system is TEP’s largest BESS to date, and it is scheduled for commercial operation in 2025.

The investor-owned utility (IOU) selected DEPCOM Power to design, build, and maintain the project across the system’s 20-year design life. The utility’s process for evaluating and engaging an Engineering, Procurement, and Construction (EPC) partner provides an operating framework for other utilities and asset owners to consider for their own successful BESS projects.

What Utilities Look for When Evaluating an EPC

An experienced EPC can utilize its knowledge and capabilities to identify the best-fit technology and then design and construct the project to meet the owner’s needs and maximize its value.

- Ability to customize design options for unique goals: To start, an EPC should consider the utility’s IRP (Integrated Resource Plan) to develop a customized approach for its grid transition, energy mix, and other goals. It should also have the capabilities to support implementation. If a strategic partner does not take this individualized approach, it could be a red flag.

- Multiple design options and technologies: Part of a customized approach includes an EPC’s ability to evaluate the range of applicable technologies, the project use cases, the applications, the internal value components, as well as the capital investment.

- Ability to facilitate: An EPC that can identify and expedite optimal solutions for size, land constraints, project approvals, and internal financial goals can smooth the process of moving through the design and build phases. With significant assets at stake, a utility will benefit from the peace of mind an experienced facilitator can provide.

- Integrated O&M capabilities: An EPC with operations and maintenance (O&M) capabilities is more likely to have operating experience and an owner’s mentality. Rather than exiting the partnership after a build, this type of EPC is committed for the long term and will design and maintain with this strategic perspective in mind.

- Partner vs. vendor mindset: A true partner does more than simply bid on a project. An EPC that operates at the “tip of the spear” and regularly evaluates the latest battery and integrated BESS container manufacturing for safety, energy density, cost, controls, and PCS integration provides significant value beyond project inception.

Partnering for BESS Success – A Case Study

An evaluation framework helps the asset owner select a partner against key imperatives – but the “proof is in the pudding.” Comparing results to the original selection criteria confirms the integrity of the framework. The following TEP case study brings this process to life.

TEP conducted an extensive evaluation and ultimately selected DEPCOM to design, procure, engineer and build its Roadrunner Reserve BESS at its Vail Substation. These detailed results, based on the evaluation points offered above, offer a benchmark of point-by-point comparison:

- Ability to customize design options for unique goals: The Roadrunner Reserve project supports TEP’s outlined goals to reduce carbon emissions by 80 percent by 2035 and add 2,240 MWs of wind and solar generation and 1,330 MWs of energy storage by 2038. TEP plans to maximize use of low-cost solar energy, charging the system during the day and delivering stored energy to meet on-peak demand. Roadrunner Reserve is expected to generate savings and ensure reliability for TEP and its customers, providing enough energy to serve up to 42,000 homes for up to four hours when deploying at full capacity.

- Multiple design options and technologies: TEP’s RFP specified the ability to evaluate multiple options to integrate renewables onto its grid. DEPCOM examined and resourced the best-fit technology, and as a result, the project has an injection power capability of 200 MW for four hours over a 20-year lifespan. The total BESS Beginning of Life Energy content will exceed 1GWh. What’s more, the system design has over 66 Power Conversion Systems teamed with 360 battery containers all designed with the latest UL and NFPA safety standards to ensure project life.

- Ability to facilitate: After evaluating load growth and projecting future peak demand in its service area, TEP recognized the need for an EPC with utility-scale resources and experience to design and install its system to manage peak demand.

- O&M capabilities: TEP’s specifications were exceedingly clear: its chosen EPC would need to be able to offer two decades of system reliability. DEPCOM’s ability to combine EPC with a long-term services agreement and dedicated O&M capability stood out as a major differentiator.

- Long-term partnership: With a plan to own and operate the power plant for 20 years, TEP identified a few notable aspects of this project that affected its decision-making process. First, Roadrunner Reserve is its first major BESS project and the largest in its fleet (also one of the largest in the US). Second, TEP wanted a partner that will work side-by-side over the entire 20-year span, not build the project and move on. The current agreement between TEP and DEPCOM is for the life of the project.

Compounding Benefits

Of course, not every consideration or benefit fits in a box. The Roadrunner Reserve project is providing benefits beyond its initial outlined criteria.

- Integration with current substation and infrastructure: TEP and DEPCOM’s in-house design engineers and planners evaluated the current Vail substation location and designed Roadrunner Reserve around land use constraints and future plans. The team was able to minimize the footprint while maximizing the layout and optimizing the approved design.

- Scalable utilization: The beauty of a utility owning the asset is it has access to all of the power and energy of the system. TEP Is not limited to the 800MWh or 200MW of dispatch. Rather, its system is designed to solve peak energy demand supply problems from projected load growth as well as provide flexible energy use/dispatch for any needs going forward.

- Capacity assurance: Growing demand for renewable energy and the project landscape of the energy transformation environment require a long-term focus. DEPCOM worked with the OEM to design a system and augmentation strategy to meet TEP’s requirements and capacity needs for its full project lifespan.

- Use case and projected additional uses: Often IOUs first target peak load reduction and management of renewable energy intermittency, and then add in ancillary services such as volt-var management and frequency control. Renewable energy additions can exacerbate integration issues. The battery technology was chosen with OEM degradation schedules, and the final design accounted for overbuild and augmentation.

Win-Win Partnerships

Utilities are poised to reap even greater benefits of the renewable energy transition while also benefiting community stakeholders and reducing emissions in the power generation space. Utilizing proven criteria to select a strategic partner with a mutual benefit mindset can accelerate this process and yield optimal results.

About the author

Greg Weyl serves as DEPCOM’s VP of Business Development in its energy storage division. He brings eight years of energy storage business development and deployment experience ranging from C&I to utility-scale battery storage systems. With 5.6 GWs of utility solar project leadership and 2,300 MWh of energy storage experience, DEPCOM creates superior value as a one-source solutions partner across the electrical energy sector.