7FA.04 (AGP) Gas Turbine Component Repairs – Enhancing Performance and Cost Savings

Mechanical Dynamics & Analysis (MD&A) is a leading provider of gas turbine component repairs. With a focus on maintaining optimal performance and reducing operating costs for our customers. MD&A has developed a range of repair processes for 7FA.04 advanced gas path (AGP) components. Significant savings can be realized by opting for lower-cost repaired spares instead of new parts.

Our experts have over 15 years of experience in repairing single crystal gas turbine blades. We have repaired over 4,000 blades made of materials equivalent to the 7FA.04 1st blade (Rene-N4).

7FA.04 components can be repaired using MD&A’s procedures which aim to extend their life while enhancing performance.

Repairing 7FA.04 Buckets:

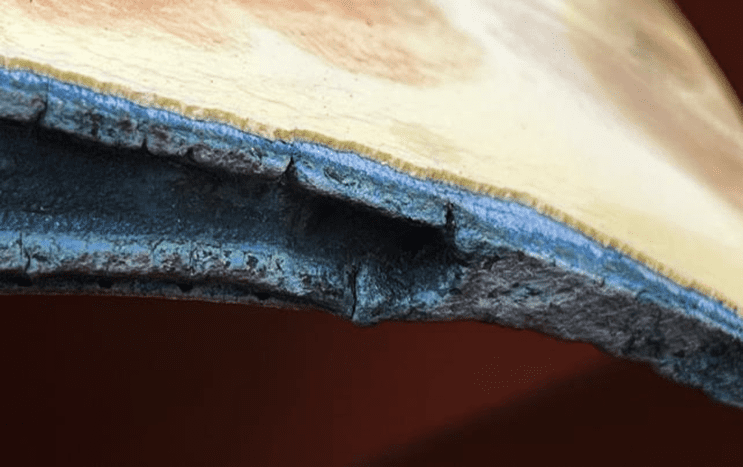

MD&A has also developed a comprehensive repair process for 7FA.04 1st stage buckets, addressing various issues commonly observed in the incoming condition. Problems such as tip cracks, tip cap oxidation, and wall thinning, as well as airfoil TBC coating missing with oxidation through the bond coat and into the parent material.The 7FA.04 1st stage bucket tip restoration process includes the removal of all cracks and airfoil damage, single crystal proprietary weld processes using high-quality materials, and the installation of a new tip cap.

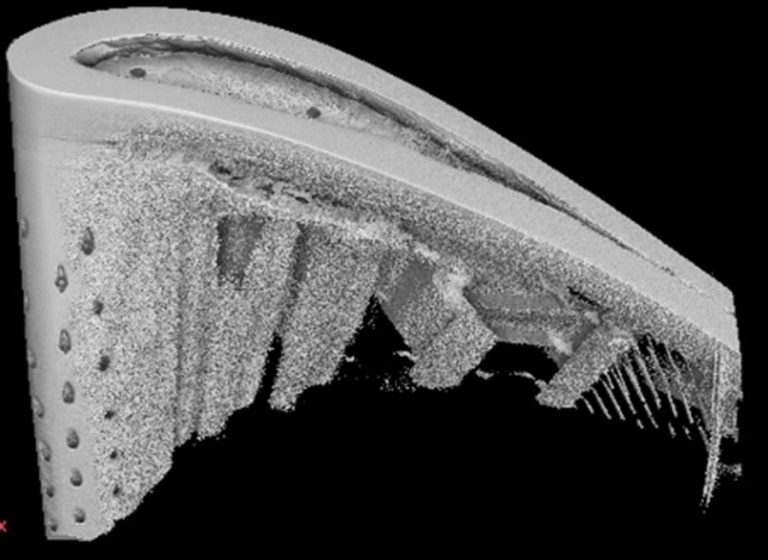

MD&A implemented CT Scanning (3D X-ray) and white light scanning to develop the optimal welding techniques to ensure a top-quality tip welding restoration structure. Metallurgical testing was performed to ensure that the process produced buckets free of cracks and re-crystallization at the airfoil tip cap. The weld material above the tip cap is a high oxidation and erosion resistant structure that is proven to perform well in single crystal blades at high firing temperatures experienced in AGP applications.

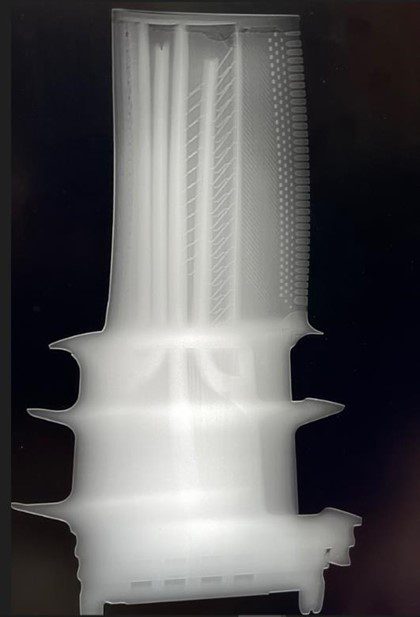

The final configuration of the blade tip is accomplished by using a multi-electrode configuration tool during the electrical discharge machine process (EDM). After re-establishing the tip geometry, all new cooling holes are established to ensure proper tip cooling. The tip restoration technique ensures no double or triple drilling cooling holes. This provides the best airfoil tip cap integrity. All components are then x-ray inspected and airflow tested.

Once the repairs and pre-coat inspections are complete, MD&A experts apply a NiCoCrAlY HVOF bond coat. This coating is derived from military gas turbine technology and contains additional elements such as Hafnium and yttrium that provides for a superior oxidation resistant bond coat. MD&A offers a low conductivity (Low-K) Thermal Barrier Coating that helps reduce the bulk operating temperature of the 7FA.04 1st Stage bucket. Lowering the operating temperature provides for the long-term preservation during the operational lifespan of the component.

The MD&A blade tip restoration technique has been fully demonstrated in directionally solidified (DS) and single crystal (SC) components. Evaluation and measurements of blade tip repairs after operation have demonstrated improved optimization of the blade tip height. Keeping most of the original tip height during operation provides the best turbine performance.

In one case study comparison versus the OEM, MD&A’s blade repair procedures have proven to be highly effective, resulting in several benefits for customers. These include minimal loss of blade tip height, which helps maintain turbine performance, as well as, low erosion and oxidation of the repaired blade tips. MD&A’s repairs also exhibit excellent abrasion resistance against the thermal barrier coating (TBC) of 1st shroud tiles.

MD&A has successfully repaired over 4,000 single crystal blades, resulting in approximately millions of dollars of savings for customers. These repairs have enabled blades to operate at higher firing temperatures, contributing to improved turbine efficiency.

Experts in AGP Gas Turbine Component Repairs

MD&A has also performed inspections on 7FA.04 (AGP) 2nd Stage Blades & 3rd Stage Blades.

Our facility has leading-edge equipment and repair techniques with proven expertise on multiple-frame gas turbine hot gas path and combustion components.

Our team has extensive knowledge on a range of gas turbine component repairs, including weld repair, blend repair, dimensional restoration, and machining.

Our expert technicians are well-trained, seasoned professionals with in-depth knowledge of the many strict tolerances, procedures, and specifications to complete each repair.

Repairing Nozzles & Shrouds

MD&A experts have also repaired 7FA.04 1st shroud tiles. This repair involves implementing true abradable coatings in new and repaired tiles to minimize stress on the blade tip during rubbing incidents.

MD&A’s repair expertise extends to gas turbine nozzles, including the 1st and 2nd stages.

Similar repair experience are Nickel-based V94.3A2 2nd and 3rd vanes with our weld/braze repair method refined over 15 years. Our experts have successfully repaired 45 sets and returned them to service.

For 7FA.04 2nd stage nozzles, our experts have made an alloy change and combined weld repair with braze repair.

MD&A specializes in the repair of several key gas turbine components across different models, allowing our customers to extend the lifespan of their equipment and optimize operational efficiency.

- 6FA/7FA/9FA Repairs: We offer comprehensive repairs for the 1st, 2nd, and 3rd buckets, nozzles, shroud blocks, liners, transition pieces (TP), flow sleeves, and caps in 6FA, 7FA, and 9FA gas turbines.

- 7EA Repairs: Our expertise extends to repairing 1st, 2nd, and 3rd buckets, nozzles, shroud blocks, liners, transition pieces (TP), flow sleeves, and cowl caps in 7EA gas turbines.

- V94.3A and V84.3A Repairs: We provide repairs for 1st, 2nd, 3rd, and 4th blades, 1st, 2nd, 3rd, and 4th vanes, as well as the 1st outer seal in V94.3A and V84.3A gas turbines.

- GT24/GT26 Repairs: Our repair capabilities encompass HPT1 blades/vanes and LPT1, LPT2, LPT3, and LPT4 blades/vanes in GT24 and GT26 gas turbines, with ongoing development in the repair processes.

MD&A is an industry leader in AGP gas turbine component repairs and has earned customer trust across the globe. Our expertise in repairing various gas turbine models allows our experts to constantly sharpen their skill set and brings both depth and breadth of experience to your parts lifecycle. We believe our historical track record of success is an important fact that differentiates our service from those available elsewhere in the industry.

Through meticulous repair processes and commitment to continuous improvement, MD&A delivers cost-effective solutions, enhanced performance, and extends the lifespan of gas turbine components.

For more information about our AGP gas turbine component repairs and services, please visit our website or use our contact form.