Latest

-

Gas

This month in POWER (OCTOBER)

October 1886 In the late 19th century, efficient combustion of solid fuels was achieved more by trial and error than by a fundamental understanding of stoichiometry and staged combustion. Boiler manufacturers took many different approaches to the challenge. Some made sense; others didn’t. In which category does the design described below fall? In 1886 the […]

-

Commentary

Competition policy: The best path

Winston Churchill once said, “Democracy is the worst form of government—except for all the others.” The same could be said for competition policy in wholesale power markets. Competition policy has its flaws. It is not perfect, but it is better than the alternatives. One alternative is to rely completely on vertical integration and […]

-

Nuclear

Nuclear plants: Something old, something new

The recent restart of Tennessee Valley Authority’s (TVA’s) Brown’s Ferry Unit 1 following a five-year renovation brings to 104 the number of nuclear plants operating in the U.S. Their 100 gigawatts of capacity represent about 20% of the nation’s electricity supply. If American electricity demand doubles by 2030 (as the U.S. Energy Information Administration predicts), […]

-

Coal

Global Monitor (September 2007)

Constellation files partial COL / IAEA scrutinizes shaken Japanese nuke / Wave energy of the future? / New GE plant reigns in Spain / Solar house competition heats up / Oxygen-blown IGCC, at micro-scale / Turning corncobs into ethanol / Court blocks gas attack on coal project / New advanced energy initiatives / POWER digest

-

O&M

Focus on O&M (September 2007)

Replace pumps, cut repair bills / New bolts show their stress level / Up a certain creek, without a filter / Hang up those cables and hoses

-

Legal & Regulatory

Carbon-neutral status shouldn’t be for sale

While elected officials in Washington debate the politics of climate change, state legislators and regulators have been busy putting in place programs to reduce greenhouse gas emissions. For the most part, the goals of the programs reflect desired changes to power supply and consumption: increasing the efficiency of electricity generation and delivery, using less fossil […]

-

Gas

Al Ezzel Power Plant, Isle of Muharraq, Bahrain

Bahrain began privatizing its electricity and water-supply sectors three years ago, and the Al Ezzel Power Plant represents the first fruit of that strategic shift. The 950-MW plant, powered by two identical 2 x 1 combined-cycle units that burn natural gas, went commercial in May of this year. The plant now supplies about half of the national grid’s demand. The success of this fast-track project demonstrates the advantages of free markets and the wisdom of bringing in experts to build new capacity.

-

Gas

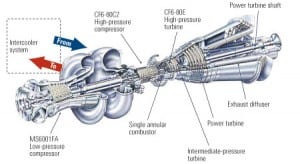

Groton Generating Station, Groton, South Dakota

This plant’s main claim to fame: It marks the commercial debut of GE’s 100-MW LMS100 gas turbine-generator. According to Basin Electric, over the unit’s first year of service it has demonstrated top-notch operating flexibility in peaking, mid-range, and baseload service, thanks to capabilities such as 10-minute cold start-ups and minimal impact on heat rate at partial loads. In addition to hosting the first LMS100, Groton Generating Station earns recognition as one of POWER’s Top Plants for the attention its design pays to reliability and resource planning.

-

Gas

GTAA Cogeneration Complex, Mississauga, Ontario, Canada

When a blackout shuts down a factory, the impact isn’t apparent to the public. But lose power at an international airport, and thousands of angry travelers and the people waiting for them won’t be interested in excuses. The Greater Toronto Airports Authority learned that lesson in August 2003. Ten months later, it began building a 117-MW cogeneration plant that is now capable of supplying all of its energy needs—not just electricity, but space heating and chilled water as well.

-

Gas

Port Arthur II Integrated Hydrogen/Cogeneration Facility, Port Arthur, Texas

The rationale for a typical cogeneration plant is clear: Supply some power, and maybe some steam, to an industrial host and save energy dollars on both sides of the fence. But integrating a cogen plant that also produces hydrogen with a major refinery that operates 24/7 is a job best left to a company with diverse and proven technology skills. The Air Products Port Arthur II project proves that such a job can be done right. Accordingly, it is one of POWER’s natural gas–fired Top Plants of 2007.