Ameren Missouri faced a pivotal moment in its growth and reliability journeys. The large investor-owned utility identified a high-risk section in its St. Louis-area service: aging manual switchgear combined with a growing base of commercial and industrial customers. This need was made evident by:

- Extended Outages. Cable faults caused lengthy outages that were difficult to locate before restoring affected customers.

- Aging Infrastructure. Legacy gear was live-front pad-mounted switchgear that was degrading due to This resulted in diminishing reliability and resilience in the densely industrialized area.

- Vulnerability to Storms. Customer minutes of interruption (CMI) numbers rose during inclement weather events.

To boost reliability and decrease restoration time in this area, Ameren Missouri decided to automate the switching from a manual system with four substation buses involving 10 total feeders to an automated scheme—one that would remain effective and flexible for years to come. “We don’t spend hours hunting for faults anymore. Now, we can pinpoint the problem more quickly,” said Andy Sugg, senior manager with Ameren Missouri.

The Solution

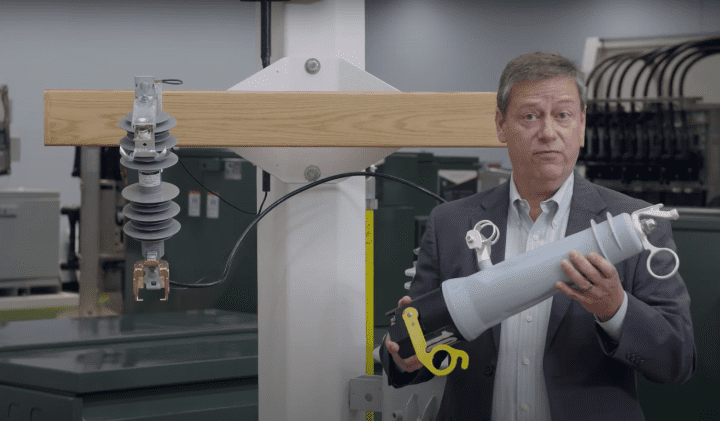

To enact its automation plan, Ameren Missouri turned to S&C Electric Company. Starting with its switchgear units, Ameren Missouri replaced 33% of its install base with S&C Electric’s Remote Supervisory PME Pad-Mounted Switchgear (Figure 1). This automated gear offered several key features that could withstand severe weather and quicken restoration, including:

- Dead-front, air-insulated design.

- Encased components.

- Sophisticated source-transfer control capabilities.

To enhance its newly automated system, Ameren Missouri integrated S&C IntelliTeam II Automatic Restoration System with its devices. This software incorporates distributed intelligence on the grid and creates a faster response with real-time system information. It achieves this by:

- Grouping automated devices into “teams” that transfer vital information to each other and work together to find the optimal path to reroute power and restore service.

- Preventing overloading during source transfer by automatically detecting which nearby substation has the capacity to handle the additional load.

- Supporting complex systems of virtually any size.

To facilitate systemwide communications, Ameren Missouri opted for private LTE connectivity. The utility built its own cell towers that it fully owns and operates.

Before Ameren Missouri deployed S&C Electric’s automation devices, S&C Electric ran factory acceptance tests to show how the solutions operate in various contingency scenarios and to assure the utility the system works in a predictable, optimal way. “By using our own LTE connectivity, we consolidate our communications infrastructure and can easily control our system, even as technologies evolve in the future,” said Labbeb Quaisi, career engineer at Ameren Missouri.

Better Metrics, Proven Results

From initial design to installation and deployment, Ameren Missouri’s underground automation initiative took only nine months to complete. The utility began seeing results almost immediately.

Since the automation system’s deployment, Ameren Missouri’s systemwide CMI during inclement weather events has been reduced by 15% to 25% per storm, and the area’s SAIDI (System Average Interruption Duration Index) has improved by 70%. During that time, S&C Electric’s solutions performed fault location and isolation, and automatic power rerouting to minimize outages during three separate events.

Event 1—The Substation. When one of Ameren Missouri’s substations experienced a complete outage, its adjacent feeders automatically rerouted power to keep the power on until the substation could be repaired.

Event 2—The Car Crash. S&C Electric’s pad-mounted equipment is hardy and solid, but when a car crashed into one of the units, it caused significant damage—and an electrical fault. Fortunately, the new system restored service to surrounding customers while the damaged equipment was out of commission.

Event 3—The Underground Fault. When a fault occurred on one of Ameren Missouri’s underground lines, the new system’s isolation scheme isolated the faulted section quickly and restored power to all the unfaulted sections. The Ameren Missouri crew only had to examine five sections of cable to determine what faulted before restoring power to these remaining customers. The faulted section was quickly identified by using Faulted Circuit Indicators in conjunction with the automated switchgear.

When comparing the results of these three post-automation events with the lengthy outages under the previous system, the power of S&C Electric’s automation systems is clear: improved reliability; dramatically shorter restoration times; and simple, efficient operations.

A System Built to Scale

Encouraged by the results of its automation initiative, Ameren Missouri has expanded underground automation in more areas on its system with similar results. Since S&C Electric’s solutions are built with interoperability and end-to-end automation in mind, Ameren Missouri is confident in its system’s scalability.

“We can easily drop S&C Electric devices into existing schemes to make them better. We know they will integrate smoothly and simply—and we won’t have to redo all the logic,” said Quaisi.

With this system now providing more reliable, resilient service to its critical customers, Ameren Missouri can build on its success using S&C Electric’s simple, scalable automation solutions.

—Joe Matamoros is Chief Product Development Officer with S&C Electric Company.