In This Issue

-

Commentary

Coal Lobby Message Missing the Mark

Demonstrating sound knowledge, having profound passion, and being consistent with your message are essential when trying to persuade someone to adopt your point of view. A recent press briefing hosted by a well-known pro-coal industry group failed on all counts.

-

Coal

EPA Preparing Regulations for Coal Plant Ash

New coal-fired power plant ash management regulations appear to be inevitable, perhaps as soon as year-end. The Tennessee Valley Authority and Edison Electric Institute are on board with new regulations, as long as the ash is regulated as a nonhazardous waste under the Resource Conservation and Recovery Act.

-

Coal

UK Sets Binding Carbon Cuts; Requires CCS at Coal Plants

The UK has all but doomed new coal-fired capacity by simultaneously setting binding carbon reduction goals and by requiring carbon capture and sequestration (CCS) of carbon emissions from new mid-size coal-fired power plants. Existing plants will also be required to retrofit their plants when CCS technology is demonstrated, now estimated to happen by 2020.

-

Commentary

Auctioning Allowances Will Not Cut Carbon Emissions Faster

Utilities generally support a cap-and-trade approach to reducing carbon emissions—but only when the objective of any legislation is to promote cost-effective reductions. The least-cost alternative for consumers requires free distribution of all carbon allowances.

-

Coal

FirstEnergy Retools Coal Plant to Burn Biomass

FirstEnergy has announced plans to repower two coal-fired units at the R.E. Burger plant to burn biomass. Conversion of the two units, expected to be completed by 2012, gets the utility off the hot seat with the EPA for alleged Clean Air Act violations.

-

O&M

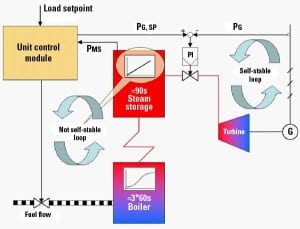

A New Era in Power Plant Control Performance

Recent improvements in the performance of steam power plants have been achieved with advanced computerized controls. These new control schemes not only reduce fuel consumption and make the plant much more responsive, but they also can significantly decrease start-up commissioning time and cost.

-

Coal

Commercial Experience with Concrete-Friendly Mercury Sorbents

Commonly, 20% of the cement (by weight) in a concrete mix is replaced by fly ash. Fly ash enhances the workability, durability, and ultimate strength of concrete at a lower cost than cement. However, mercury sorbents can change the ash properties to make it unsuitable as a concrete additive. New “concrete-friendly” sorbents can keep the revenues from ash sales flowing.

-

O&M

Better Combustion Airflow Monitoring at the Hunan Yiyang Power Plant

Measuring combustion airflow in a coal-fired power plant can be problematic when using annubar instruments that feature small holes that can easily plug with coal dust. Sierra Instruments eliminates this big maintenance headache with its more-accurate, nonplugging thermal mass flow meter design.