Water

-

Water

Oak Creek Power Plant Upgrades Cooling Water System

Formed suction intake designs have been used in many large vertical pump stations in flood control projects. Space limitations at the Oak Creek Power Plant Expansion Project near Milwaukee, Wisconsin, created a unique opportunity to apply this technology to an 800,000-gpm cooling water system upgrade for the entire Oak Creek Power Plant.

-

O&M

Conserve Water by Improving Cooling Tower Efficiency

Though an abundant supply of freshwater has been taken for granted in many parts of the world, its availability is becoming less certain, even in North America. Water is a valuable resource and commodity that needs to be efficiently managed to minimize waste, reduce energy consumption, and control cost, especially for power generation. The industry must respond by seeking out more efficient ways to use water, such as by implementing water recycling and reuse strategies, especially for critical equipment like cooling towers.

-

Water

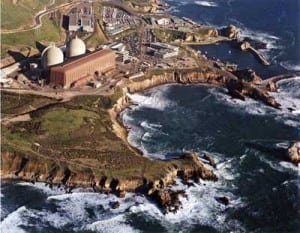

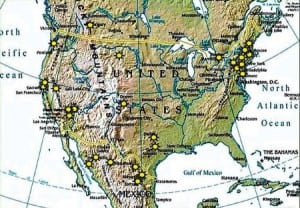

Invasive Species and Water Intakes

On October 21, a mass of basketball-sized jellyfish managed to accomplish what activists of every stripe had failed to do: Abruptly shut down Pacific Gas & Electric Corp.’s (PG&E) 1,118-MW Diablo Canyon Unit 2 reactor in San Luis Obispo County, Calif. (Figure 8).

-

Water

Cooling water intake structure regulations

In the wake of a recent federal case, large power plants are off the hook for now as far as complying with the U.S. Environmental Protection Agency’s (EPA’s) 2004 rule intended to protect fish and other aquatic organisms by controlling cooling water intake practices.

-

O&M

Put a lid on rising chemical costs

News reports tell us that rapidly growing economies, such as China’s, are importing more oil and raw materials each year, thereby pushing up commodity prices on the world market. One of the side effects of rising commodity prices is considerable increases in the cost of water treatment chemicals. Don’t be tempted to skimp on chemicals to save a buck but risk catastrophic damage. In the words of NASA’s former flight director, Gene Kranz: “Failure is not an option.”

-

O&M

Focus on O&M (September 2008)

Tackling substandard water sources / Control abrasive wear in scrubber piping / Sensors and final control elements

-

Water

Air-cooled condensers eliminate plant water use

River or ocean water has been the mainstay for condensing turbine exhaust steam since the first steam turbine began generating electricity. A primary challenge facing today’s plant developers, especially in drought-prone regions, is incorporating processes that reduce plant water use and consumption. One solution is to shed the conventional mindset that once-through cooling is the only option and adopt dry cooling technologies that reduce plant water use from a flood to a few sips.

-

Water

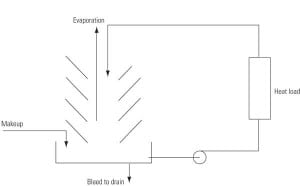

Wet surface air coolers minimize water use by maximizing heat transfer efficiency

Gas-fired power plant designers and operators are increasingly challenged to reduce their plants’ water consumption and improve their thermal efficiency. Closed-loop, evaporative cooling systems (known as wet surface air coolers, or WSACs) are a cost-effective heat transfer technology that can simultaneously achieve both goals. In addition to providing lower-temperature cooling and condensing while requiring less space and horsepower than conventional systems, WSACs can use poor-quality water as spray makeup.

-

O&M

Condensate polishers add operating reliability and flexibility

Many of today’s advanced steam generators favor either an all-volatile treatment or oxygenated treatment chemistry program, both of which require strict maintenance of an ultra-pure boiler feedwater or condensate system. Those requirements are many times at odds with the lower-quality water sources, such as graywater, available for plant makeup and cooling water. Adding a condensate polisher can be a simple, cost-effective solution.

-

Water

New strategies for conquering environmental challenges

No doubt some power plant engineers feel that tackling environmental problems is a lot like dealing with the Hydra, the ancient mythological serpent monster with multiple heads. When an attacker would cut off one of the Hydra’s numerous heads, two new ones would grow back in place of the head that was removed. All too […]