O&M

-

O&M

When to Use an Oil Skimmer

Oil skimmers are very effective in removing oil from wastewater before discharge but are also perhaps the most efficient and economical approach.

-

O&M

Four Methods of Fly Ash Sampling

There are four approaches to measuring fly ash content and, therefore, the quality of fuel combustion in a boiler. Before choosing one, you should understand their relative levels of complexity and accuracy.

-

O&M

Ceramics Win the War on Erosion

Erosion can significantly reduce the operational life of boiler components. Abrasion-resistant ceramic parts can be a sound alternative to expensive metallic parts when replacing boiler components.

-

O&M

World’s Largest Circulating Fluidized Bed Boiler Begins Commercial Operation

When the Åagisza power plant began commercial operation in late June 2009, it marked the beginning of a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of this 460-MW plant is the world’s largest CFB boiler, which is also the world’s first once-through unit supercritical CFB boiler.

-

O&M

Rebuilding Feedwater Heaters While a Plant Is Online

Rebuilding aged feedwater heaters can make better economic sense than buying new ones, because rebuilding reduces capital cost and plant outage expenses. At one Texas generating station, rebuilding saved one-third the cost of a new feedwater heater while improving the plant’s heat rate.

-

O&M

Halar-Lined Chimney Remains Maintenance-Free

A fiberglass-reinforced plastic (FRP) Halar stack liner was installed at Vattenfall’s 300-MW Unit 2 at the Nordjylland Power Station in 1995. The 112-meter-high (367-ft) stack, protected from corrosion by the ECTFE liner, is still in excellent condition and has not required any repairs during more than 13 years of service. (ECTFE is short for ethylene chlorotrifluoroethlyene polymer, marketed under the brand name Halar ECTFE [Halar] by Solvay Solexis.)

-

O&M

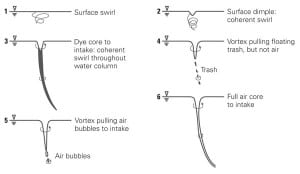

Scale Model Testing Confirms Adequate Refueling Water Storage Tank Vortex Allowance

Recent Nuclear Regulatory Commission (NRC) Component Design Bases Inspection activities have scrutinized empirical approaches used to determine vortex allowances for emergency core cooling system (ECCS) suction sources.

-

O&M

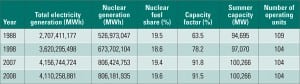

Benchmarking Nuclear Plant Operating Costs

In an exclusive agreement with the EUCG Nuclear Committee, POWER was provided access to some key, high-level performance and operational data from the group’s nuclear industry benchmarking database. All U.S., and many international, nuclear power plants are members of the committee and have contributed to its database for many years. This month we introduce you to the EUCG Nuclear Committee and share sample nuclear operating costs. Look for future reports on other key performance benchmarking metrics during 2010.

-

O&M

Modeling and Simulation Tools Reduce Plant Outage Duration

Replacing equipment inside a nuclear power plant requires careful planning that begins many months before the plant outage. Entergy has adopted advanced modeling and simulation tools that allow engineers to "walk through" the entire outage in a virtual model, thus avoiding unanticipated surprises.

-

O&M

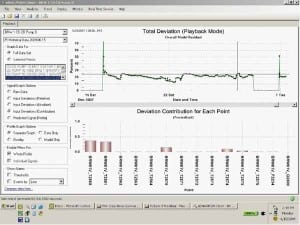

Catching Faults with Centralized Condition Monitoring

In 2007, Exelon Corp. began the Centralized Performance Monitoring (CPM) pilot program. The goal was to reduce downtime costs and lost revenue associated with the 25% of unplanned forced losses across its fleet of 17 nuclear power units without additionally taxing existing personnel or adding new personnel.