O&M

-

O&M

The Unique Challenge of Controlling Biomass-Fired Boilers

Biomass has many advantages as a fuel for boilers: It’s inexpensive, readily available in many regions, CO2 neutral, and its use warrants government subsidies. The fuel also presents unique concerns to the designers, owners, and operators of biomass plants, especially in the design of the control system.

-

O&M

Competitive Maintenance Strategies, Part II

Nearly every combined-cycle operator recognizes that cycling reduces the life expectancy of hot-gas-path components in combustion turbines. Often overlooked, however, is that the same phenomenon affects the heat-recovery steam generator (HRSG).

-

O&M

A Primer on Optimizing Fleet Operations

The power industry needs a straightforward definition of "fleet optimization" and a game plan to achieve the promised economic gains of optimizing. This need has become more urgent because integrating nondispatchable renewable resources requires more complex optimization strategies. The bottom-up approach presented here applies well-understood optimization principles and techniques that will help power producers minimize their fleetwide cost of production, independent of the technologies used to generate electricity.

-

O&M

Enhanced Condenser Tube Designs Improve Plant Performance

Enhanced condenser tube designs can significantly improve the heat rate and performance of fossil and nuclear plants. Using the optimum number of tubes and replacement tube sheets will cost more than simply replacing plain tubes. However, the investment’s simple payback is measured in only weeks, which builds a strong case for using an enhanced tube design as part of your next condenser overhaul.

-

O&M

Deciphering Desuperheater Failures

The "combined" portion of a combined-cycle plant is the heat-recovery steam generator (HRSG) that generates high-pressure and high-temperature steam and the steam turbine generator that expands the steam to produce electricity. Integrating the HRSG and steam turbine with the combustion turbine is a key challenge for plant designers, as each system has differing operating profiles, operational constraints, and design requirements.

-

O&M

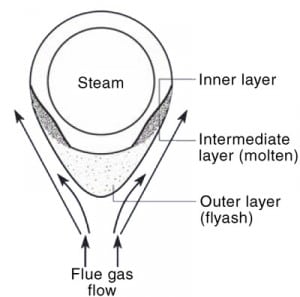

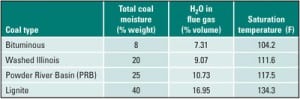

The Role of Fireside Corrosion on Boiler Tube Failures, Part I

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. Three case studies examine the different failure modes experienced by tubes located throughout the furnace.

-

O&M

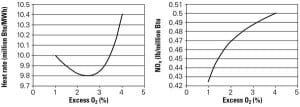

Power 101: Flue Gas Heat Recovery in Power Plants, Part I

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we begin a series of Power 101 tutorials that present these fundamentals in a clear and concise way. First up are the essentials of recovering heat from flue gas.

-

O&M

Venezuela’s Power System on Brink of Collapse

Venezuela, a country that relies on hydropower for almost three-quarters of its electricity, has been battling a deepening electricity crisis since a drought in 2009 and a sudden 7% surge in demand brought the country’s power system to the brink of collapse.

-

O&M

Competitive Maintenance Strategies

Many consultants are prospering today by creating "new" maintenance strategies. What they’re really creating is new buzzwords.

-

O&M

Restraining Torsional Vibration

All rotating equipment power trains found in a power plant have some amount of vibration, usually caused by mechanical unbalance of the rotating system, shaft misalignment, or weakness in the bearing support.