Instrumentation & Controls

-

Coal

Curbing the blue plume: SO3 formation and mitigation

Understanding why stack emissions become opaque leads to better choices of systems for controlling SO3 and other pollutants, based on current and future plant operating configurations.

-

Coal

How accurate primary airflow measurements improve plant performance

Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that underestimate primary airflow levels can lead to negative operational outcomes that include increased boiler gas temperatures, flyash loss-on-ignition, excessive NOx emissions, and higher-than-necessary fan power consumption. We remind you how to avoid those headaches.

-

Instrumentation & Controls

Solving plant vibration problems

Solving insidious vibration problems in rotating equipment may sometimes seem like a black art that requires the right incantation. But identifying the root cause of the vibration is actually a science. By using cutting-edge vibration measurement tools in concert with computer simulations, plant operators can arrive at a permanent, cost-effective solution to virtually any vibration […]

-

Instrumentation & Controls

Siemens units keep pace

Earlier this February, Siemens Power Generation’s (SPG’s) factory in Berlin delivered its 500th gas turbine. The SGT5-4000F (Figure 2), formerly called the V94.3A, is nominally rated at 270 MW and weighs in at about 300 metric tons. With this shipment, the Berlin facility can boast of having built gas turbines with a cumulative capacity of […]

-

Instrumentation & Controls

Steam turbine upgrading: Low-hanging fruit

In 1500, Leonardo Da Vinci drew sketches of a device that rotated when hot air going up a chimney passed through a set of fan-like blades. Leonardo called his invention a "chimney jack," and although it only turned a roasting skewer, it gave birth to the idea of mounting blades on a shaft to convert […]

-

Instrumentation & Controls

A permanent solution to generator vibration problems

Remember the slogan, "Never trust anyone over thirty?" Chances are you’ve joined the ranks of the over-thirty generation and are dealing with your own personal "maintenance" issues—not unlike the fleet of generators at larger U.S. power plants, whose average age is about 30. Given the continuing growth in U.S. electricity demand and the cost and […]

-

Instrumentation & Controls

Brain surgery breathes new life into aging plants

Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager number of students pursuing engineering degrees, and the accelerated retirement of the older workers who make up the industry’s experience base. On top of this, […]

-

Instrumentation & Controls

Designing steam cycles to avoid corrosion

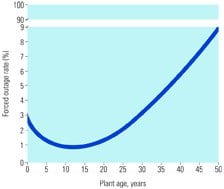

U.S. power producers and owners of industrial steam systems each spend about $15.4 billion annually to combat corrosion in their plants. Scale and deposits are thought to be responsible for another $20 billion a year in reduced plant efficiency and lost generation capacity. Corrosion is the primary cause of every other forced outage, and the […]

-

Instrumentation & Controls

Air heater leakage: Worse than you think

Rotary regenerative air heaters capture and recycle about 60% of the heat energy exiting the boiler—energy that would otherwise go up the stack. For a 500-MW coal-fired plant, the recycled energy amounts to about 1.5 billion Btu per hour, and reusing it reduces fuel consumption by about 1,500 tons per day. Although most performance engineers […]

-