Coal

-

Coal

From GHG to Useful Materials

Could the transformation of carbon dioxide (CO2) into carbonates and oxides solve the problem of greenhouse gas emissions (GHG) from fossil-fired power plants? Some companies are betting that such processes could make everyone happy and even create new profits. Buzz has been growing about this approach, though the concept has been around for many years.

-

Coal

Big Bend’s Multi-Unit SCR Retrofit

Tampa Electric will soon complete a comprehensive selective catalytic reduction project on all four units at its Big Bend Power Station that will make Big Bend among the cleanest coal plants in the U.S. The project — the centerpiece of the company’s 10-year, $1.2 billion air quality improvement program — is on schedule to meet all of its air quality improvement goals by mid-2010.

-

Coal

Big Stone Remodels ESP into Pulse Jet Fabric Filter

Short of replacement, what are your options when your original electrostatic precipitator fails to meet your current emissions and opacity requirements? The management of Big Stone Plant chose the unconventional, yet economic approach of building a pulse jet fabric filter inside the casing of the old electrostatic precipitator. The upgrades restored plant availability and prepare the plant to meet the next regulated reductions in particulate matter emissions.

-

Coal

Real-Time Control of Coal Quality Improves Reliability

Poor lignite fuel quality had plagued the Red Hills Power Plant since it began operation eight years ago. The solution: real-time measurement of coal properties that has allowed Red Hills Mine to carefully monitor fuel quality and adjust fuel collection processes to ensure that only high-quality fuel is delivered to the plant. Now all delivered fuel is consumed, and plant reliability is much improved. It’s a classic win-win project.

-

Coal

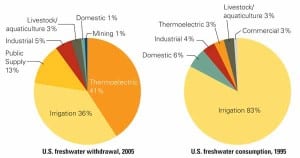

Determining Carbon Capture and Sequestration’s Water Demands

The U.S. Department of Energy’s National Energy Technology Laboratory is pursuing a new integrated energy-water R&D program that addresses water management issues relative to coal-fired power generation that takes into account the major impacts of CCS on water use. The goal of this research is to promote more efficient use of water in power plant operations and increase the availability of heretofore unusable waters for power plant use. Those practices can mitigate the impacts of CCS on power plant water use and allow for continued development of energy resources.

-

Coal

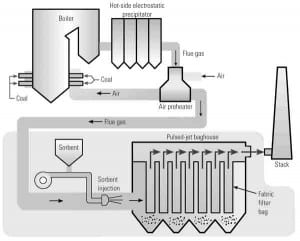

NETL, We Energies Successfully Complete TOXECON Demonstration

A three-year demonstration of the TOXECON process, a technology to reduce mercury emissions while increasing the collection efficiency of particulate matter (PM), was last year successfully completed at a Michigan coal power plant, the U.S. Department of Energy’s National Energy Technology Laboratory (NETL) reported in January.

-

O&M

Conveyor Upgrades Increase Plant Availability, Reduce Airborne Dust

The loading and discharge of conveyor belts is the area where many, if not most, of the problems in solids conveying occur. Fortunately, a new technology provides chutes to accomplish conveyor loading and discharge without blockages while minimizing the dust generated: engineered-flow transfer chutes.

-

Coal

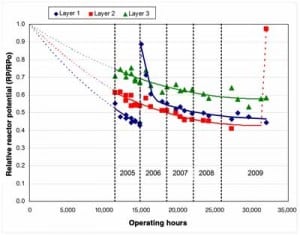

KnoxCheck Reports Reactor Potential and Catalyst Activity

Adding a selective catalytic reduction (SCR) system to an operating coal-fired plant may be an expensive and time-consuming project, but the environmental benefits are without question. However, once construction is complete and operations staff assume control of the SCR, proper measurement tools are required to monitor the catalyst performance life cycle.

-

O&M

A Game Plan for Improving Boiler Operations

Operating a boiler is not difficult, but operating a boiler safely and efficiently requires skill and proper training. Following boiler operation best practices will keep your equipment in like-new condition for years to come. This game plan includes a compendium of best practices, with web links to a number of additional key resources you should be famililar with.

-

Coal

EPA Proposes To Tighten Ozone Standard

In one of the most far-reaching of numerous new air regulations expected from the Obama administration, the Environmental Protection Agency (EPA) has proposed to tighten the primary federal standard for ground-level ozone, the principal constituent of smog, to within a range of 60 to 70 parts per billion, saying the tougher standard is needed to protect human health.