Compliance with one of the latest federal environmental regulations, the Effluent Limitations Guidelines (ELG), can be both costly and complicated. A newly available option offers features and capabilities that may make it a more attractive alternative than conventional approaches.

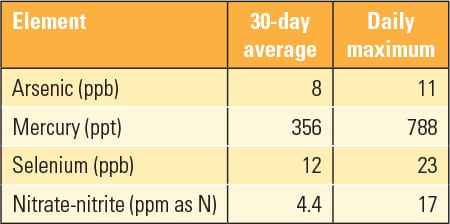

In September 2015, the U.S. Environmental Protection Agency (EPA) finalized a new rule affecting flue gas desulfurization (FGD) wastewater discharges from coal-burning steam electric power generation units by setting stringent federal limits on total suspended solids (TSS), arsenic, mercury, nitrate/nitrite, and selenium (Table 1).

|

|

Table 1. Steam Electric Effluent Limitation Guidelines for flue gas desulfurization wastewater (existing sources). Source: EPA |

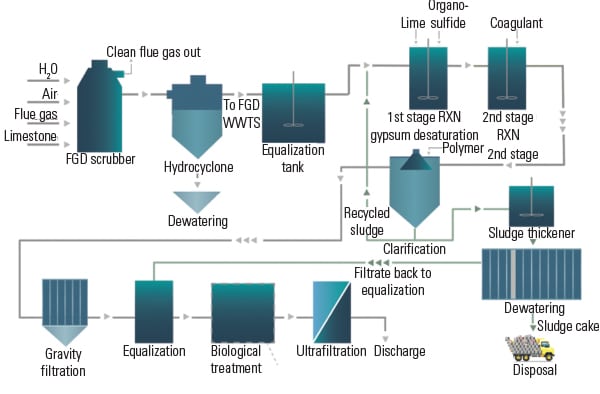

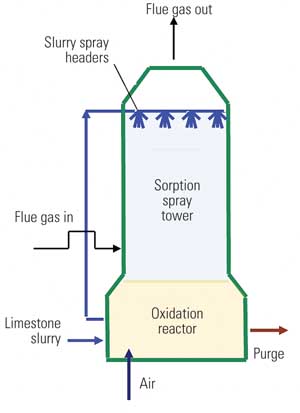

The final Effluent Limitations Guidelines (ELG), as it is known, establishes effluent limitations based on best available technology economically achievable (BAT) and is based on “technological availability, economic achievability, and other statutory factors and is intended to reflect the highest performance in the industry.” The ELG rule identifies a technology basis for BAT for FGD that includes a “chemical precipitation system [Figure 1] that employs hydroxide precipitation, sulfide precipitation (organosulfide), and iron coprecipitation, followed by an anoxic/anaerobic fixed film biological treatment system designed to remove heavy metals, selenium and nitrate.”

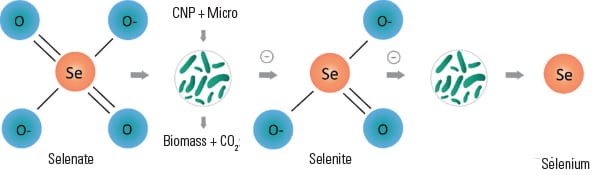

In a biologically based approach to wastewater treatment, specialized microorganisms are cultured in an engineered bioreactor to maintain environmental conditions that facilitate transformation of contaminants from a soluble and toxic form to a solid product that can be safely handled and disposed. In the case of selenium, microbial respiration is performed by certain bacteria when nitrate, a more energetically favorable electron acceptor, is depleted, and bacteria respire selenate as a substitute terminal electron acceptor to produce selenite.

The process continues with a decrease in oxidation reduction potential (ORP) through selenite to form an insoluble precipitate of elemental selenium (Figure 2). Under the right conditions, this precipitate can be retained in the bioreactor and periodically wasted from the system in a concentrated form.

|

|

2. Good bacteria at work. Microbial respiration is used to achieve selenate reduction to elemental selenium. Source: Frontier Water |

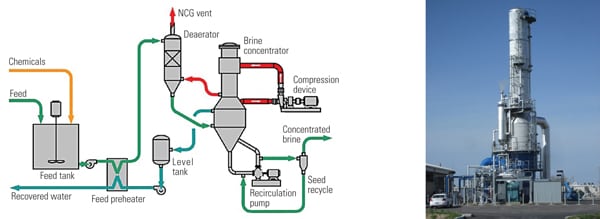

System Proven with Other Challenging Wastewater

Frontier Water Systems has been focused for the past four years on the research, development, design, and manufacturing of prefabricated, modular process equipment solutions for the treatment of selenium, mercury, and nitrate from wastewaters associated with power generation and mining.

The result is the trademarked SeHAWK family of products, engineered to deliver guaranteed water quality performance in a prefabricated solution that saves time and cost. The original SeHAWK series bioreactors serve the mining industry (Figure 3), while the SeHAWK FGD product is specifically designed to integrate with a physical/chemical pretreatment system to meet ELG compliance.

|

|

3. SeHAWK 500 prefabricated bioreactor installation for mine water treatment. Courtesy: Frontier Water |

The SeHAWK FGD process is unique in that it incorporates a fluidized first-stage reactor that continually expels the significant volume of gas that forms during the biochemical transformation of FGD wastewater from an oxic to anoxic form. In traditional downflow reactors, a consideration in sizing is allowing for retention of this volume and the downtime associated with expelling this gas plus the additional waste volume that is generated from flushing.

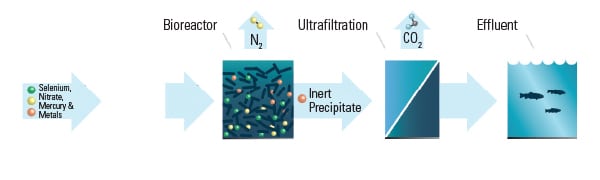

The SeHAWK FGD system also directly integrates fixed film anoxic biological treatment with ultrafiltration (UF) to maintain a more consistent effluent water quality (Figure 4).

|

|

4. Integration. The SeHAWK FGD process incorporates the bioreactor with ultrafiltration. Source: Frontier Water |

In the SeHAWK system, UF is employed as a pressure-driven process that achieves separation through sieving (that is, size exclusion), depending on its pore size and molecular weight cut-off. Typically, UF membranes in the range of 80 kDa to 150 kDa (equivalent to a pore size of 0.02 μm to 0.03 μm) are used in water treatment applications as they have a good balance between rejection and permeability. This pore size can provide a barrier to viruses often found in water sources and generally produces an effluent with a turbidity of less than 0.2 NTU and TSS of <1 mg/l.

The integration of post-UF captures the residual selenium and mercury particulate material that is not retained in the bioreactor. Particulate mercury, contained in coal, is released through volatilization in a boiler and converted to elemental mercury Hg0. A fraction of the total mercury leaving a boiler is captured in particulate control equipment while the remaining mercury is either absorbed during FGD treatment or released to the atmosphere.

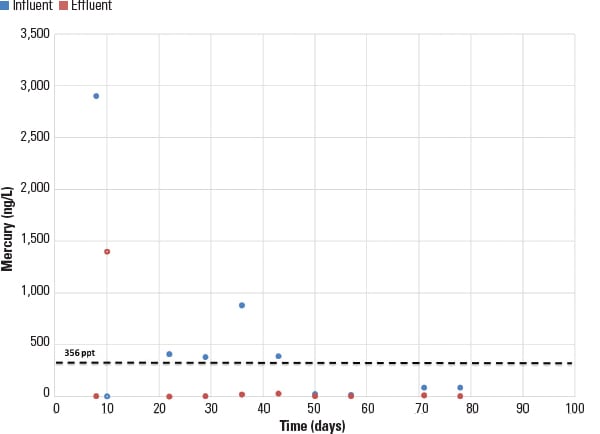

Dissolved mercury in the form of Hg2+ is removed from FGD wastewater via physical-chemical treatment using organosulfide in combination with iron co-precipitation. As mercury sulfide precipitates form, colloidal particles with a diameter of <0.2µm can be produced and pass through clarification and bioreactor stages. Although there is reduction and retention of mercury in the bioreactor, it is not always sufficient to meet ELG mercury standards alone. In these instances, UF provides a beneficial polishing step to remove colloidal particles and achieve very low effluent ppt mercury levels (Figure 5).

|

|

5. SeHAWK FGD mercury performance example. Source: Frontier Water |

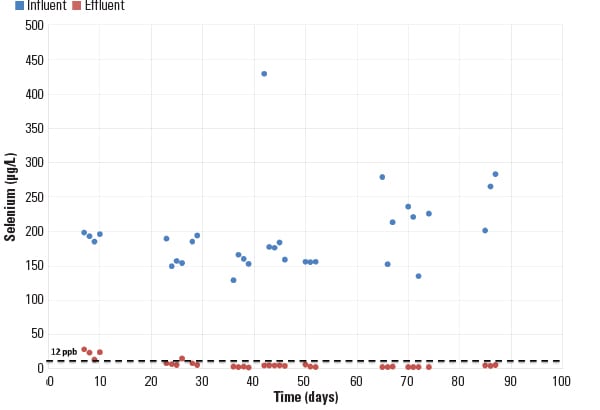

Selenium performance is also improved with post ultrafiltration (Figure 6), as the removal of insoluble selenium associated with effluent TSS is rejected by the membrane. This approach contributes to a smaller footprint and shorter bioreactor retention time.

|

|

6. SeHAWK FGD selenium performance example. Source: Frontier Water |

Addressing Compliance Timeframe and Complexity

In order to reach the compliance goals mandated by the EPA, it is estimated that between 60 and 80 coal-burning stations are wrestling with the economics of installing treatment in the form of a bioreactor, deploying a zero-liquid discharge system, or decommissioning the operation entirely. Depending on the facility, the timeframe for incorporation into a National Pollutant Discharge Elimination System (NPDES) permit ranges from November 2018 to December 2023.

This schedule puts pressure on utilities, consulting engineers, equipment suppliers, and contractors to provide accurate cost estimates and project schedules in short order against an uncertain economic and regulatory landscape. Given the limited number of groups with the background and capacity to deliver specialized custom solutions of this nature, it is logical that a standardized, repeatable platform that can be rapidly and cost-effectively implemented is timely and valuable.

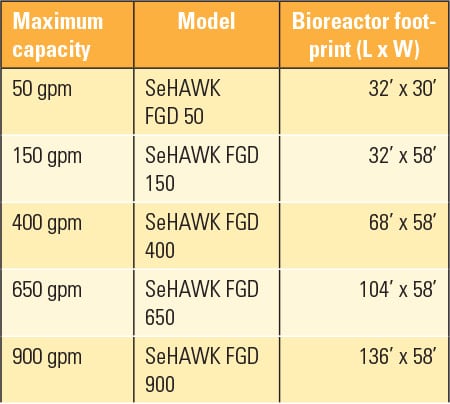

Frontier Water estimates that over 80% of these sites will have wastewater flows less than 900 gpm. To address this range of capacity, the SeHAWK FGD series of prefabricated modular treatment solutions (Figure 7) is designed and built around a comprehensive scope that includes prefabricated tanks, skid-mounted equipment, access platforms, and railings. It also integrates with a variety of control platforms, including Emerson’s Ovation distributed control system. All equipment uses corrosion-resistant materials, tested and selected with input from partner utilities and validated in demonstration-scale field trials.

|

|

7. SeHAWK FGD 50 Installation. Courtesy: Frontier Water |

SeHAWK FGD systems are expandable by adding unit biological trains and supporting equipment skids to deliver consistent water quality against a range of influent water chemistry, as shown in Table 2.

|

|

Table 2. SeHAWK FGD models and footprints. Source: Frontier Water |

By using this transformative approach, the capital expenditure for BAT technology implementation—including engineering, procurement, and construction—for ELG wastewater compliance is significantly lower than original estimates, and the solution can be delivered in a condensed timeframe. ■

—James Peterson PE is Co-Founder and CEO of Frontier Water Systems.