As combined cycle gas turbine plants are called upon to play a larger and more flexible role in the generation mix, it’s important to schedule a comprehensive assessment of major components at key intervals to ensure reliable operation.

Just like humans, power plants can benefit from regularly scheduled condition assessments, which are sometimes called “health assessments” or “health checks.” That’s especially true when you’ve got a plant with a new type of equipment or when equipment has been used in ways it wasn’t originally designed for.

The North American combined cycle fleet is a good example, and though turbines get most of the attention, heat recovery steam generators (HRSGs) also feel the effects of stressful performance. Using experience drawn from many projects across the fleet as a way to demonstrate the common challenges these systems face, this article sheds light on some of the most common problems HRSGs are likely to exhibit when they hit the 10-year mark.

While varying in scope, the goal of HRSG assessments is to go beyond routine repairs and confront both short-term and long-term issues. These assessments provide an owner/operator with the proper due diligence for major maintenance planning and capital expenditures and are used in a variety of ways, including:

■ Five-year capital planning on major equipment

■ Five-year major maintenance planning

■ Development of outage and non-outage preventive maintenance actions and work orders

■ Development of new operator rounds and checks

■ Modification or creation of new predictive maintenance monitoring

Because most of the modern combined cycle fleet is largely at or quickly approaching mid-life, corporate management needs to assess whether there are unanticipated capital expenditure (CAPEX) projects that should be addressed in strategic planning and budgeting. A horizon of the next 10 years is commonly used because the plant will be approaching the end of its original design life beyond that time, and instituting a major upgrade will yield limited payback in terms of increased availability and reliability if deferred until later.

A 10-year projection also is likely to encompass a time when the plants will have a gas turbine (GT) outage that is long enough to accommodate major capital projects such as superheater/reheater tube panel replacements, attemperator piping system upgrades, replacement of high-pressure (HP) evaporator tube panels, and the like. This is especially important as more and more plants are extending the period between longer repair outages. These evaluations also consider the scope of current, regularly scheduled inspections, and maintenance activities to identify whether there are larger issues to address.

Identifying HRSG Patient Problems

The HRSG condition assessments are often initiated after onsite meetings with plant management, including the plant manager, maintenance manager, operations manager, plant engineer, and the corporate asset manager. Direct and early input from the plants is critical to rapidly get up to speed on plant-specific history, concerns, and the differing markets and dispatch for each plant.

Onsite meetings are used to receive a summary of unit history and operations issues from plant staff, to discuss ongoing programs for important programs such as water chemistry control actions to control flow-accelerated corrosion (FAC), and to identify upgrades that the plant has already implemented.

Standardized Evaluation

Following an onsite meeting, data requests are issued to the plant to accumulate historical information from plant records on prior operating experience, known damage issues, recently installed upgrades, outstanding recommendations from mechanical contractors, original equipment manufacturers (OEMs)/vendors and third-party consultants for discretionary repairs and modifications, and general plant engineering information.

Data is extracted from third-party reports, plant operating data is requested, and repair histories are gleaned from National Board Inspection Code (NBIC) R1 reports, and related mechanical contractor work records. These data are often provided electronically for use in the assessment.

While varying in detail for each plant, the HRSG condition assessment consists of similar activities. In addition to inspection reports, the assessment team discusses recommendations from prior activities to verify what actions have been implemented, and which are planned but not implemented. Overall, the condition assessment is composed of activities that are the responsibility of the fleet owner and activities that are the responsibility of the HRSG consultant.

Summary of HRSG characteristics and operating profile (by the plant):

■ Known issues affecting HRSG reliable lifetime

■ HRSG OEM advisories and available upgrades

■ HRSG pressure part and structure failure history

■ HRSG field inspection reports

HRSG condition assessment elements (by Tetra):

■ Review current HRSG condition

■ Evaluate HRSG issues that have not been addressed or that have been incompletely or inadequately addressed

■ Examine compliance with general HRSG maintenance and operational guidelines

■ Recommend action items

Information collected and reviewed in this process is compiled and evaluated with respect to issues most important to improve or maintain HRSG reliability. Plant-specific reports are prepared to provide management with recommendations for the next five to 10 years.

Factors Affecting Reliable HRSG Life

Most combined cycle plants in the North American fleet were designed and constructed during the initial bubble of rapid expansion of natural gas–fired power plants. Over the years, many potential issues have emerged for HRSGs, including the following.

Operating factors:

■ HRSG cycling service

■ Water chemistry control and layup practice

■ High-temperature drain capacity and controls

Effects on HRSG pressure parts:

■ HP superheater and reheater (RH) panel tube failures

■ HP evaporator tube and lower header failures

■ FAC, erosive wear (EW), and liquid droplet impingement (LDI) thinning of low-pressure (LP) evaporator system tubes, headers, and riser piping

■ Attemperator piping thermal impingement and quench damage

■ LP economizers tube failures

■ Cold end corrosion, tube fouling, and backpressure issues

■ Corrosion under insulation

Each plant’s final report includes an evaluation of each of these potential issues plus recommended, prioritized actions grouped by HRSG panel section and component.

HRSG Failure History

A complete review of the failure history at each plant is conducted, including reviews of relevant root cause failure analyses, metallurgical laboratory reports, and related field inspection and testing records. These documents are important to identify currently active damage mechanisms, issues that have been resolved by prior repairs and alterations as well as the result of other actions to reduce the rate of damage progression (such as changes in water chemistry control and operating procedures). The data include failures that—while plant-specific—are grouped into the following common systems:

■ High-temperature pressure parts (HP superheater and reheater)

■ HP steam system

■ Intermediate pressure (IP) steam system

■ LP steam system, including external deaerator, if present

■ Interstage attemperator piping (HP/RH)

■ Other interconnecting piping

■ Small-bore piping (drains and vents)

■ Baffles, casing, penetrations, structures, and other non-pressure parts

These reviews include the review of NBIC R1 reports from prior pressure part repairs.

HRSG Inspection Report Summaries

The level of detail in available HRSG inspection reports varies substantially from plant to plant and across the fleet because different contractors provide these services (and for different purposes). The types of inspection reports reviewed in the course of an assessment include the following:

■ Warranty inspections

■ Baseline condition inspections

■ Annual inspections

■ HP evaporator deposit weight density laboratory evaluations

■ HRSG FAC/EW/LDI inspections

■ T91/P91 inspections

■ Creep inspections

■ Water chemical vendor inspections

■ Borescope/videoscope inspections

■ Statutory inspections

From these inspections, third-party inspector recommendations are compiled for comparison with Tetra’s review recommendations.

Review of Current HRSG Condition

Separate from the review of known failures and history, a detailed review of the design, inspection history, and susceptibilities to industry problems are summarized using Tetra’s experience from prior condition assessments of HRSGs with similar design and known issues for the HRSG design.

These include prior engineering studies (thermal design evaluations, metallurgical root cause failure analysis, and other engineering design projects). The assessment evaluates the current condition of each HRSG and addresses the following topics:

■ High-temperature components

■ HP, IP, and LP steam systems

■ Condensate preheater/LP economizer and feedwater supply to HP and IP economizers

■ HP and RH steam attemperation

■ Water chemistry control

■ Interconnecting piping

■ HRSG structures: transition duct, distribution grids, expansion joints (hot, cold), manway doors, structural steel (inside casing), exhaust stack, dampers, and silencers

This review identifies components whose condition warrants a change in priority for future maintenance and provides specific recommendations for such actions. Several case studies follow from recent projects.

Evaluating Operational Impacts of a New Contract on a HRSG

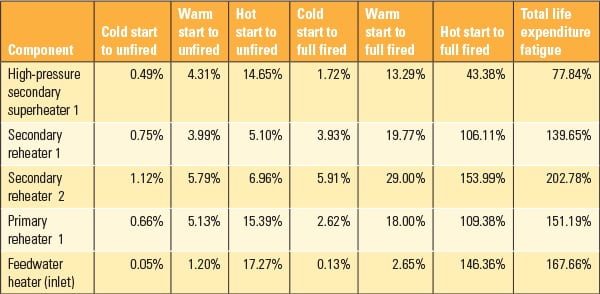

As part of a forward-looking aspect of one HRSG condition assessment, expected changes in plant operational modes were considered. At this plant, new power purchase agreements were being negotiated that required additional low-load and load-following operations. The pressure part health evaluations showed that extending these ranges, while continuing to conduct daily load changes and two shift cycling, substantially increased the required changes for superheater life consumption as well as other plant impacts.

The primary impacts of the proposed operation on variable operation and maintenance costs (VOM) were:

■ Higher HRSG operating temperatures due to higher GT outlet gas temperatures, resulting in higher superheater (SH) life consumption

■ Increased thermal stresses in HRSG due to load cycling

■ Increased wear and tear on HP/RH/LP bypass and steam conditioning valves

■ Increased potential for condenser tube damage in bypass mode

■ Increased water consumption in cooling tower in bypass mode

■ Decreased generation (and VOM payments) in ancillary service mode

The impact of this operation on VOM costs was assessed by analyzing three operating cases:

■ Low load 2 x 1 automatic generation control (AGC) service (60% to 100%) for 90 days per year

■ Low load 2 x 1 AGC service (60% to 100%) for 180 days per year

■ Low load 2 x 1 AGC service (60% to 100%) for 60 days per year plus low load 2 x 1 bypass load for 30 days per year

The primary impact of these analyses was the increased repair costs on each HRSG of HP SH #1 elements due to higher temperatures and thermal stresses in load-following service and the cost impact of reduced generation. In the bypass cases, the same factors occur, but with the addition of added water costs and allowances for potential condenser damage. Table 1 shows the results.

|

|

Table 1. Increased variable operation and maintenance costs for low-load and load-following for a 500-MW combined cycle gas turbine (CCGT) plant. Source: Tetra Engineering |

The primary contributors to the change in costs are the impact of lower generation and higher water/chemical use in the bypass case. Secondarily, the earlier replacement/repair of HP SH 1 modules in the HRSGs and budgeted condenser and valve repairs for the bypass case contribute. One key factor is that 30 days of bypass operation has the same cost impact as 100 days of non-bypass AGC operation.

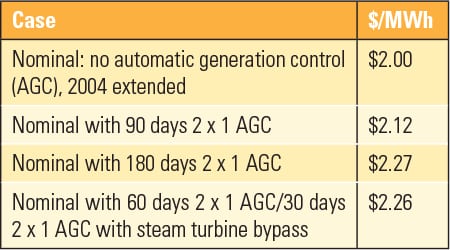

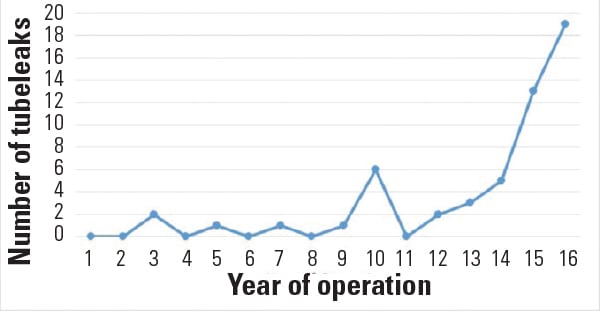

Long-Term Progression of Economizer Tube Leaks

A review of past tube leaks in a five-unit cogeneration plant HRSGs showed an increasing trend of corrosion fatigue cracks in HP economizer tubes. Figure 1 shows how the trend rapidly increased after year 12. The cause was high stresses at tube bends due to cycling. An example of the cracks that result is shown in Figure 2. This was made worse by combined IP-HP economizer lower headers in the original design. Tetra recommended splitting these to allow differential expansion. This recommended major modification is shown in Figure 3. That modification lowered stresses and reduced the incidence and progression of the tube leaks going forward.

|

|

1. Trend of corrosion-fatigue tube leaks. This image shows the progression of corrosion-fatigue high-pressure economizer tube leaks in five units over time. Source: Tetra Engineering |

|

|

2. Corrosion-fatigue cracks in economizer tubes. Here you can see corrosion-fatigue cracks on the inner diameter of the HRSG HP economizer. Courtesy: Tetra Engineering |

|

|

3. HP-IP economizer header alteration. This was the design alteration that was installed in the five units. Courtesy: Tetra Engineering |

Flow-Accelerated Corrosion Pressure Part Thinning

FAC is an issue throughout the North American fleet (Figure 4), as are creep, thermal stress/low cycle fatigue, quench failures in high-temperature panels (HP superheaters and reheaters), the potential for cold-end corrosion damage to extended heat transfer surfaces (fins) and water-side damage such as under-deposit corrosion in HP evaporators, pitting, and general corrosion in the water side of the LP components. Only some plants currently operate at ultra-low load (<50% rated MW), which can enhance problems with local overheating of pressure parts, damage caused by thermal quenching from attemperation overspray, and evaporator drum instability.

Some HRSGs have a geometry in the LP evaporator that can lead to FAC wall thinning in tubes immediately adjacent to the link connection from the LP drum downcomer interconnecting link. Enhanced FAC inspections are recommended to address this potential issue. This is a known issue for certain OEM designs.

Cold-End Corrosion, Underdeposit Corrosion, and Tube Fouling

At one plant, repeated condenser tube failures exposed the HRSG water side to seawater for an extended period. That resulted in high dissolved oxygen at times (as high as 50 ppb), general corrosion damage to pressure parts (including many HP evaporator tube leaks), a need for special inspections, and costly mechanical repairs. Cold-end fouling and the need for extensive and frequent gas-side cleaning was an issue for this plant as well (Figure 5).

Reheater tube failures were a problem early in the life at another plant, due primarily to low cycle fatigue (Figure 6). Yet another plant experienced a creep failure in a tube-header weld in a RH upper header (Figure 7) after operating 100,000 hours—well before the expected end of component life, and the first indication that a new challenge to HRSG reliability has emerged. RH drain failures are also an issue at some plants unless recent upgrades have mitigated their occurrence.

|

|

6. Failure. One plant exhibited low cycle failure of reheater 2 at the upper header after <100 starts and 12,500 hours of operation. Courtesy: Tetra Engineering |

Attemperator Piping Cracking, Thinning, and Drainage

Many plants in the fleet have had a long and beleaguered experience with leaks in the inter-stage RH attemperator piping. A few plants have completed major alterations after a series of pipe leak incidents (Figures 8 and 9).

|

|

8. Breach. One plant experienced a pipe failure in the reheater attemperator (“candy-cane” crossover link between the two RH sections). Courtesy: Tetra Engineering |

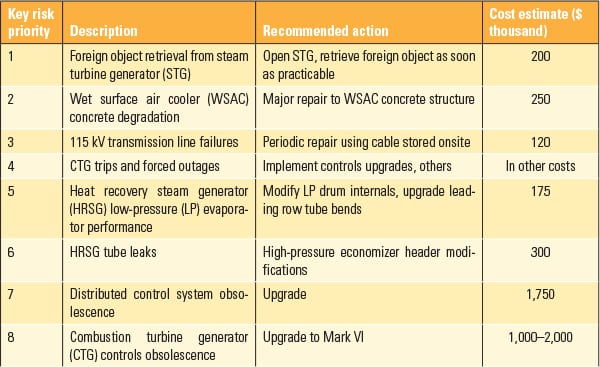

Recommended CAPEX and Maintenance Actions

Based on all the information gathered, plant-specific, prioritized recommended action items are presented in each plant’s condition assessment report to summarize prior actions or to prioritize future recommended actions (Tables 2 and 3) to improve HRSG reliability for the remainder of service life.

|

|

Table 2. Prioritized risks from low-load and load-following operation (500-MW CCGT). Source: Tetra Engineering |

Healthcare for Combined Cycle Plants

HRSG condition assessments and health checks are essentially comprehensive reviews of the condition of the HRSG that go beyond more traditional evaluations of calculated damage rates, accumulated corrosion wear, and expected remaining creep life. They also examine the actual plant history and programs for preventive maintenance and repair. In some cases, they also include calculation of additional VOM charges to account for the “extra” damage incurred by cycling and/or low-load operation.

As such, these assessments are a new way to implement a comprehensive evaluation of key issues for maintaining HRSG reliability, consistent with current and expected future plant dispatch. They have provided important and useful information for capital planning, maintenance planning, and the implementation of new and improved operator procedures and practices for many combined cycle gas turbine plants. ■

—Peter S. Jackson, PE (peter.jackson@tetra-eng.com) is director of field services and David S. Moelling, PE (david.moelling@tetra-eng.com) is chief engineer at Tetra Engineering Group.