In a milestone for the U.S. nuclear fuel cycle, the Nuclear Regulatory Commission (NRC) on Feb. 13 issued its first approval of a commercial Category II nuclear fuel fabrication facility, granting a license to TRISO-X, a wholly owned subsidiary of X-energy, which allows the company to fabricate commercial tristructural isotropic (TRISO) fuel using high-assay low-enriched uranium (HALEU) at its TRISO-X Fuel Fabrication Facility (TF3) under construction in Oak Ridge, Tennessee.

Issued under 10 CFR Part 70, the 40-year Special Nuclear Material (SNM-7007) license—expiring on Feb. 13, 2066—authorizes TRISO-X to receive, acquire, possess, and transfer special nuclear material, including uranium enriched to less than 20% U-235, for fuel fabrication at TF3, its greenfield facility which is under construction at the 110-acre Horizon Center Site in Oak Ridge, Tennessee.

While the NRC license covers TF3 (referred to as TRISO-X FFF) as a single Part 70 fuel fabrication facility, the company refers to its first commercial fabrication unit at the site as “TX-1” and plans a second unit, “TX-2,” to expand production capacity. The license includes detailed safety and safeguards conditions and requires the NRC to complete an operational readiness review before uranium may be introduced into the facility.

From Pilot to Commercial: X-energy’s Path to TRISO Fuel Production

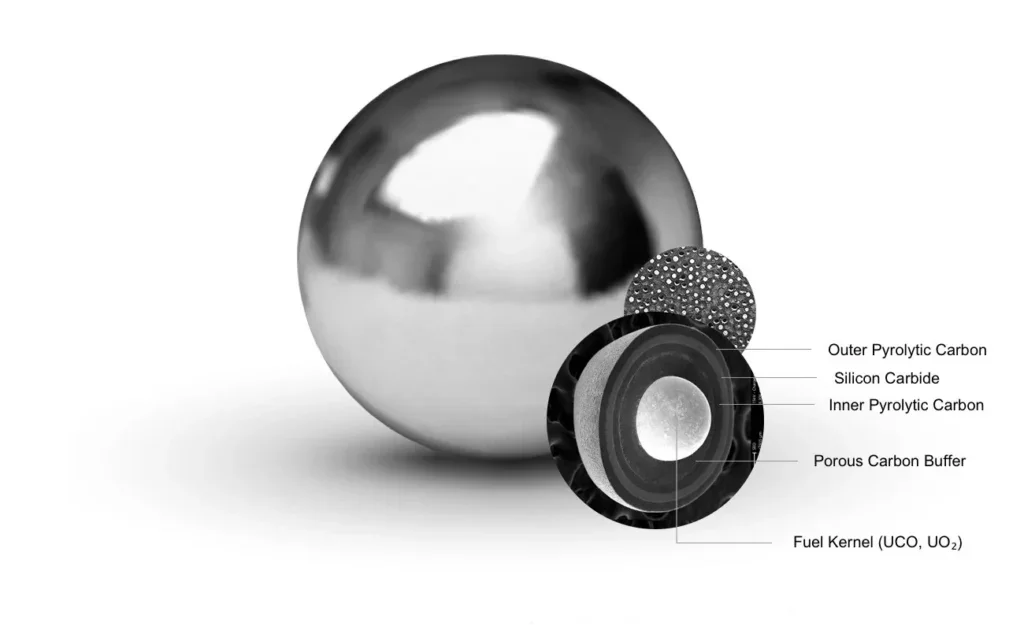

X-energy is developing the commercial fuel facility to support commercial deployment of its Xe-100 high-temperature gas-cooled reactor (HTGR) design, which will use TRISO fuel composed of poppy-seed-sized uranium kernels encapsulated in multiple layers of carbon and ceramic materials. The coated particles are embedded in graphite to form spherical fuel elements, commonly referred to as “pebbles,” designed to retain fission products at elevated temperatures.

According to NRC materials, TF3’s manufacturing process will not include any enrichment of material. Manufacturing will entail receiving HALEU in the form of triuranium octoxide (U₃O₈) powder enriched to less than 20 weight percent U-235, or uranyl nitrate solution. “The facility would convert the U₃O₈ into a uranyl nitrate solution and then into gel spheres and fuel kernels. The fuel kernels would be processed through coating, heat treatment, and carbonization. These operations would be supported by shipping and receiving, laboratory, quality control, research and development, uranium recovery, and waste disposal,” the NRC’s environmental impact statement (EIS), issued earlier this week, notes.

The facility will source feedstock from three locations: low-enriched uranium (LEU) U₃O₈ from Urenco USA’s enrichment facility in Eunice, New Mexico; HALEU U₃O₈ from the American Centrifuge Plant in Piketon, Ohio; and dilute uranyl nitrate from the Department of Energy’s (DOE’s) Savannah River Site in Aiken, South Carolina. The feedstock will be transported in NRC-licensed containers via truck.

The company, which has operated a pilot-scale TRISO fuel line at Oak Ridge National Laboratory since 2016, submitted its Part 70 license application for the TRISO-X FFF to the NRC on April 5, 2022, followed by an environmental report on Sept. 23, 2022, and a supplemental application on Dec. 30, 2024. The project is part of X-energy’s participation in the DOE’s Advanced Reactor Demonstration Program (ARDP).

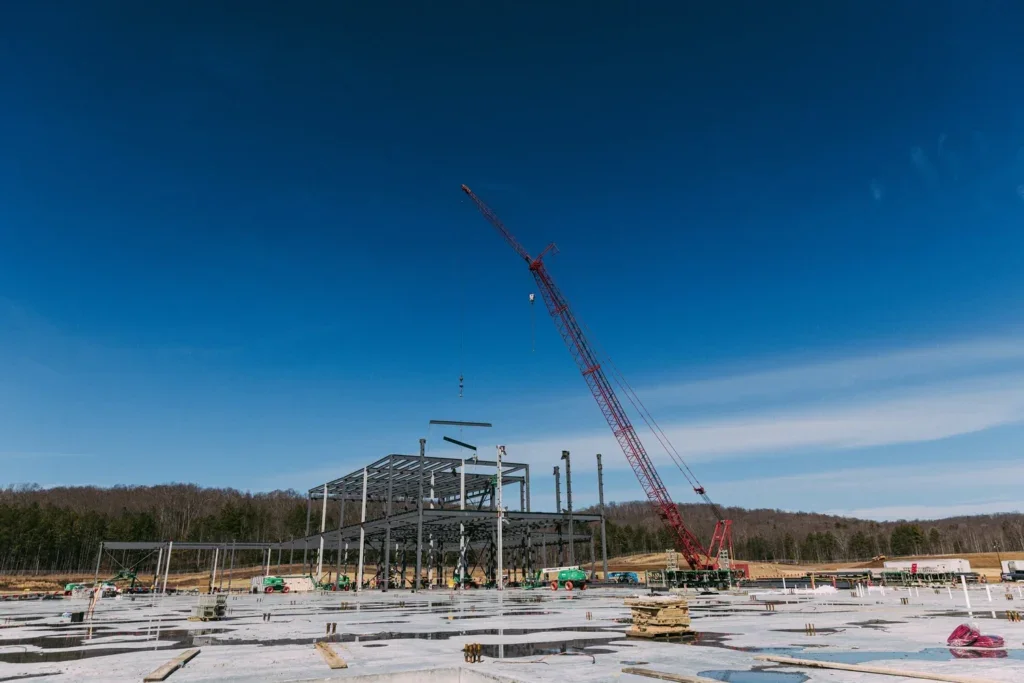

Vertical construction at the first fuel facility, TX-1, began in November 2025. According to the project’s EIS, the $768 million construction phase is expected to span five years and peak at 332 workers. Work will require excavation of approximately 560,000 cubic yards of material removal and 363,000 cubic yards of engineered backfill. Construction on the core-and-shell phase of the 214,812-square-foot facility is expected to be completed by mid-2026.

For now, plans envision that TX-1 will house one production line with a capacity of 5 metric tons of uranium (MTU) per year—approximately 700,000 TRISO pebbles annually—or enough fuel for up to 11 Xe-100 reactors. TX-2 will house two additional production lines with a combined capacity of 20 MTU per year, bringing the facility’s total capacity to 25 MTU per year, which X-energy envisions will operate 24/7.

Initial fuel production is expected to support the four-unit 320-MWe Long Mott Generating Station planned for Dow’s Seadrift Operations in Calhoun County, Texas. NRC review is underway under an 18-month schedule for Long Mott’s construction permit application, filed in March 2025, and could be issued later this year. The EIS notes, however, that TRISO-X plans to produce TRISO-based coated particles and final fuel forms “in various shapes and configurations to power its own advanced nuclear reactors and the anticipated fleet of advanced nuclear reactors.”

X-energy, notably, is also working with Energy Northwest and Amazon to build an Xe-100 HTGR in Benton County, Washington—the Cascade Advanced Energy Facility, initially a 4-unit, 320-MW plant, which has plans to expand to 12 units as part of Amazon’s strategy to bring more than 5 GW of new power projects online by 2039. In September 2025, the company signed a joint development agreement with British utility Centrica to deploy a fleet of up to 6 GW of Xe-100 capacity in the UK. Its preferred first project is a 12-unit, 960-MW deployment at the Hartlepool site, which is targeting first power in the mid-2030s. The company has also completed a feasibility study for Xe-100 deployment in Alberta, Canada. To support its global pipeline, X-energy recently secured a 16-unit Xe-100 component reservation with manufacturing partner Doosan Enerbility, which is committing to a new SMR component factory in Changwon, South Korea, with capacity to support approximately 20 Xe-100 reactors annually at full production.

Still, while the NRC license is a major triumph, before operations can begin, TRISO-X must obtain additional permits, including air quality operating permits from Tennessee regulators, Department of Transportation registration for hazardous materials transportation, and state radioactive material licenses, according to the project’s EIS. Construction is proceeding under separate City of Oak Ridge permits issued in 2024 and 2025.

NRC’s First-Ever Approval for a Category II Fuel Fabrication Facility

Under NRC regulations (10 CFR 70.4), fuel fabrication facilities are categorized by the quantity and enrichment level of special nuclear material (SNM) they are authorized to possess. Category II facilities, such as TRISO-X, may handle special nuclear material of moderate strategic significance, including 10,000 grams or more of U-235 contained in uranium enriched to 10% or more but less than 20%—the HALEU enrichment range—in quantities that remain below the “formula quantity” of strategic special nuclear material that defines Category I facilities

By comparison, Category I plants may possess formula quantities of highly enriched uranium (20% or greater U-235), U-233, or plutonium and support missions such as naval reactor fuel production and weapons material down-blending. Category III facilities are limited to material of low strategic significance, including uranium enriched above natural uranium but less than 10% U-235, which is typical of conventional light water reactor (LWR) fuel. Category II facilities, notably, require physical protections applicable to SNM of moderate strategic significance under 10 CFR 73.67.

X-energy noted that before it receives SNM and officially kicks off operations at TX-1, the NRC will conduct a final inspection. “This inspection will verify that equipment is ready for service, required safety systems and items relied on for safety are installed and functional, and that license-mandated programs and procedures are in place. It will also confirm that operating personnel are trained and qualified to safely begin operations,” it said.

According to the NRC, the license application was approved three months ahead of the published schedule “due to multiple efficiencies applied in the staff’s review processes.” The NRC’s review included a safety and security review and an environmental review. A Safety Evaluation Report (SER) documenting the technical review will be made public within 30 days. The project’s Environmental Impact Statement (EIS), notably, was published Feb. 12, 2026—one day before the license was issued.

“Commercial-scale production of this fuel is key to enabling the deployment of advanced reactor designs,” said NRC Chairman Ho K. Nieh on Friday. “This license represents an important milestone that supports the Department of Energy’s program to accelerate deployment of nuclear technologies and deliver more power to the grid.”

A TRISO Fuel Strategy for an 11-GW Pipeline

For X-energy, the decision has been monumental. “Regulatory approval brings us one step closer to a resilient, American fuel supply for next-generation nuclear technology, advancing our energy security by closing a longstanding gap in the U.S. nuclear fuel cycle,” said Joel Duling, president of TRISO-X. “Achieving this first-of-its-kind license reflects the technical leadership and sustained diligence of the TRISO-X team, as well as a focused process with the NRC to complete the review three months ahead of schedule. We look forward to continuing our work to bring commercial-scale TRISO production to East Tennessee.”

The company noted that while TX-2 is currently in the design phase, it would “significantly scale TRISO fuel production capacity to support X-energy’s 11 GW commercial pipeline, which it said is “equivalent to 144 Xe-100 small modular reactors, as well as other SMR developers.” Full-scale production at TX-1 and TX-2 “is expected to establish a stable commercial source of TRISO fuel for the first time in U.S. history, directly supporting energy and national security priorities by helping to close a major gap in the current U.S. and allied nuclear fuel cycle,” the company said on Friday.

Beyond X-energy, several other U.S. companies are advancing TRISO fuel production. In December 2025, BWX Technologies (BWXT), which operates a TRISO production line at its Specialty Fuels Fabrication Facility in Lynchburg, Virginia, delivered a full core of TRISO fuel for the Pentagon’s Project Pele microreactor.

A Military TRISO FirstProject Pele, the Department of War’s (DOW’s) first-of-its-kind transportable nuclear microreactor prototype, received its tri-structural isotropic (TRISO) particle fuel in December 2025 at Idaho National Laboratory (INL), where formal system testing is slated to begin as early as 2027. The fuel—manufactured by BWXT Technologies (BWXT) and shipped from its Lynchburg, Virginia, facility—represents the first TRISO microreactor fuel delivered at its final destination and builds on more than two decades of TRISO fuel development and qualification work. For more, see POWER‘s in-depth story: A First for Military Nuclear Power: TRISO Fuel Arrives at Project Pele

|

Last week, BWXT announced significant progress in producing TRISO fuel compacts for Antares Nuclear, an advanced reactor developer targeting criticality by July 4, 2026. Fuel fabrication, which began in October 2025, is on track for timely completion, it said, and when ready, the fuel will be packaged and shipped to INL, where Antares plans to conduct its reactor demonstration. BWXT is also manufacturing the HALEU that will be used in the Antares TRISO fuel compacts. And, in August 2025, BWXT launched BWXT Advanced Fuels, LLC, a subsidiary dedicated to the commercialization of advanced nuclear fuel and unveiled plans to explore establishing a new “greenfield” TRISO fabrication facility to meet growing market demand. BWXT is also collaborating with Kairos Power to optimize fuel manufacturing and explore joint development of a commercial TRISO fuel fabrication facility.

Standard Nuclear, an independent, reactor-agnostic TRISO fuel supplier, emerged from stealth in June 2025 with $42 million in venture backing after acquiring fuel manufacturing assets from now-defunct USNC. In December 2025, the company received its first shipment of HALEU feedstock at its Oak Ridge facility—becoming the first company to receive both DOE authorization and physical HALEU for advanced TRISO fuel production. The feedstock, allotted to Radiant Industries by DOE, will be processed into TRISO fuel for Radiant’s reactor demonstration scheduled for 2026. In January 2026, Standard Nuclear announced it had secured $140 million in Series A funding and officially began production of HALEU TRISO fuel under a first-of-its-kind Other Transaction Agreement with DOE that bypasses the multi-year NRC licensing process. Current capacity is approximately 500 kg annually, with plans to expand to more than 2 metric tons by mid-2026 across facilities in Oak Ridge and Idaho Falls.

Federal policy is also actively accelerating TRISO deployment through multiple coordinated initiatives. After launching the Fuel Line Pilot Program in July 2025, DOE in September 2025 announced conditional selections, naming four companies—Oklo, Terrestrial Energy, TRISO-X, and Valar Atomics—alongside Standard Nuclear, which had been previously selected. The program leverages authority under Executive Order 14301, which reformed and streamlined national laboratory processes for reactor testing, and Executive Order 14299, which directed deployment of advanced nuclear reactor technologies for national security. It seeks to strengthen domestic nuclear fuel supply chains by enabling companies to build and operate fuel fabrication facilities under DOE authorization processes that bypass initial NRC licensing requirements while providing a fast-tracked pathway to commercial licensing.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).

Editor’s Note: This story is currently evolving and subject to change. We encourage you to revisit this article or check our website for the latest updates.