The hydropower industry stands at a critical juncture where traditional operation and maintenance are quickly becoming obsolete. As global energy demand surges and grid systems become increasingly dynamic, hydropower operators face unprecedented challenges in maintaining optimal machine performance under variable operating conditions while at the same time managing aging infrastructure and reduced staffing levels. Not only is there more pressure to operate with more efficiency, less lifecycle costs, and more reliable uptime, the digital transformation is also changing the way things are run, including phasing in sophisticated on-premise and off-premise machine condition monitoring solutions.

Operation and Maintenance Practices Have Evolved

Modern hydropower operations differ significantly from their traditional counterparts. Where facilities once featured overdesigned units operating under continuous baseload conditions with well-staffed maintenance teams, today’s environment demands value-engineered units that must handle load following, peaking operations, and frequent starts and stops. This operational shift, combined with partial loading conditions that many aging machines were never designed to handle, creates new stress patterns and potential failure modes that require sophisticated monitoring approaches.

The transformation extends beyond operational demands to encompass fundamental changes in maintenance philosophy. Traditional fixed-interval maintenance strategies supported by substantial staffing resources are being replaced by predictive maintenance approaches that rely heavily on condition monitoring technologies. This evolution reflects the industry’s broader embrace of digital transformation principles, where real-time data access and predictive analytics drive operational decisions.

The Digital Infrastructure Imperative

Industry 4.0 technologies and Internet of Things capabilities are reshaping hydropower operations by providing unprecedented connectivity and data availability. These digital transformation initiatives aim to deliver real-time enterprise data access and predictive performance management tools that optimize operations, maintenance protocols, and logistics coordination.

The benefits of this digital approach extend across multiple operational dimensions. Optimal resource management becomes achievable through data-driven insights that enable faster, more accurate decision-making processes. Improved operational efficiency results from agile production capabilities that respond dynamically to grid demands while maintaining equipment reliability.

Condition monitoring systems serve as critical components within this digital infrastructure, contributing directly to increased asset utilization, reduced maintenance costs, minimized downtime, and enhanced operational efficiency. However, the evolution from traditional standalone monitoring systems with proprietary servers toward integrated enterprise-wide platforms represents a fundamental shift in data management philosophy.

Advanced Monitoring Solutions for Comprehensive Coverage

Effective hydropower monitoring requires comprehensive coverage of all critical components, including generating units, turbines, penstocks, spiral cases, draft tubes, and auxiliary equipment. The monitoring strategy must accommodate various turbine types, from Francis and Kaplan to Pelton and bulb configurations, while addressing the specific operational characteristics of each installation.

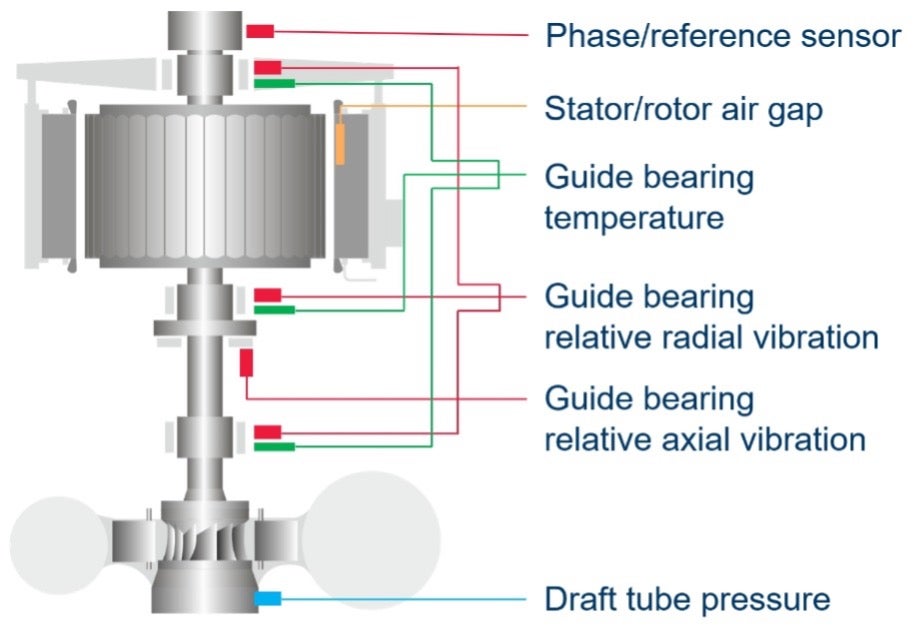

For smaller hydropower applications, vibration monitoring often provides sufficient diagnostic capability. However, larger units require additional monitoring techniques, including generator airgap analysis, rotor pole magnetic flux measurement, stator insulation partial discharge detection, draft tube pressure monitoring, and comprehensive performance parameter tracking.

Hybrid Monitoring Architectures

Modern monitoring solutions offer customizable configurations that integrate seamlessly with existing enterprise-wide data management systems, including AVEVA PI System platforms. This integration capability transforms data accessibility and security by consolidating real-time and historical information within unified dashboards equipped with multi-trend analysis capabilities and customizable alert systems. This approach allows a lot of process data and even data from other systems to be correlated together with the condition monitoring system for more diagnostic reliability. This additional data can be used in analytics done in-house, by the monitoring system or even externally by service providers. Service providers can also create customized dashboards for specific users. The condition monitoring system for such an application would be considered as an on-premise monitoring architecture, where all data is stored in the historian.

For smaller installations and balance-of-plant equipment of larger hydropower plants, wireless sensor technologies combined with artificial intelligence-powered remote monitoring services provide cost-effective alternatives. Off-premises monitoring solutions store data in cybersecure cloud services, eliminating the need for local data acquisition infrastructure when wireless sensors are deployed. This configuration enables rapid installation, configuration, and commissioning while removing the burden of server management from facility operators. The approach proves particularly valuable for operators lacking in-house diagnostic expertise or those seeking to reduce specialist workloads across multiple installations.

Contemporary hydropower condition monitoring sometimes employs hybrid architectures that combine on-premises and off-premises capabilities to optimize resource utilization and diagnostic accuracy. These architectures recognize that no single monitoring solution addresses all hydropower applications and customer requirements effectively.

Automatic Diagnostic Decision Support in Condition Monitoring Solutions

The integration of artificial intelligence and machine learning algorithms represents a significant advancement over traditional single-parameter alarm monitoring. Modern systems automatically analyze multiple vibration measurements alongside process parameters using pattern recognition techniques and digital twin models to achieve earlier fault detection and diagnostics with improved reliability. Deployment of these types of tools is advancing rapidly.

Case Study: Brazilian Hydropower Digital Transformation

A hydropower facility in Brazil demonstrates the practical implementation of comprehensive digital monitoring solutions. The installation features two 113-MW Francis turbines originally constructed in the 1970s and significantly upgraded between 2013 and 2015. Operating primarily under fixed load and synchronous condenser modes, the facility required enhanced monitoring capabilities (Figure 1) to increase turbine availability, reduce inspection frequency, and implement predictive maintenance strategies.

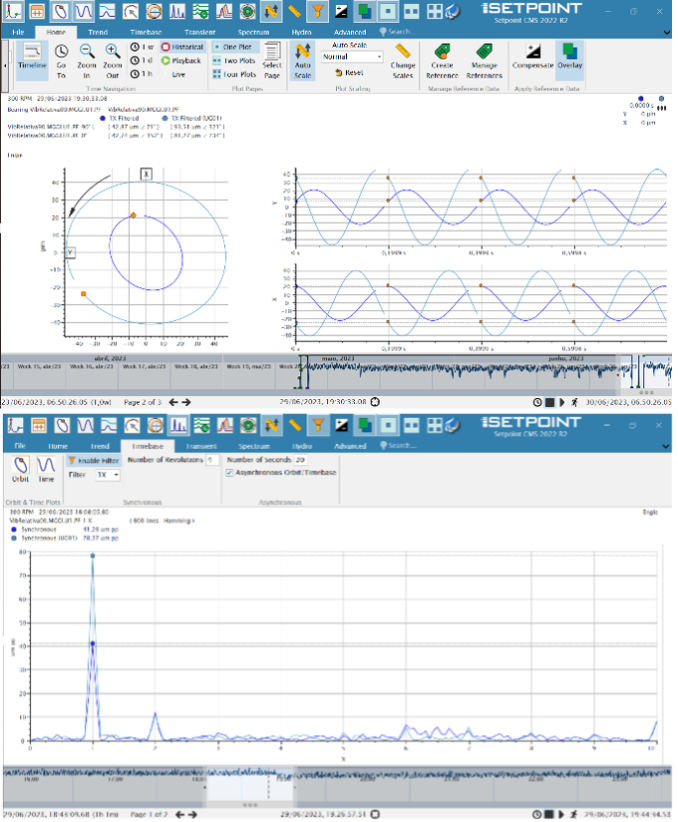

The solution involved integrating condition monitoring and diagnostic capabilities into the existing AVEVA PI System infrastructure (Figure 2), enabling real-time monitoring and data analysis that significantly enhanced operational reliability and maintenance processes. The SETPOINT monitoring system provided native integration with the enterprise historian, delivering comprehensive vibration analysis alongside specialized hydropower monitoring capabilities.

The monitoring strategy accommodated partial-load operations through load-specific alarm limits, enabling power generation across wider operational ranges (Figure 3) while avoiding hydraulic disturbances such as vortex rope turbulence and cavitation. Advanced analytics, including artificial intelligence-driven fault detection algorithms trained on data from nine hydropower stations over eight months, provided early warning capabilities that exceeded traditional monitoring approaches.

Dynamic pressure monitoring in draft tubes and comprehensive vibration analysis of guide bearings revealed the relationship between hydraulic conditions and mechanical responses across different load levels. These insights enabled operators to optimize performance while maintaining equipment integrity through predictive maintenance interventions.

Strategic Implementation Considerations

Successful hydropower condition monitoring implementation requires careful consideration of operational requirements, existing infrastructure capabilities, and long-term strategic objectives. Organizations must evaluate their diagnostic expertise levels, maintenance resource availability, and integration requirements when selecting monitoring architectures.

The choice between standalone proprietary systems and enterprise-integrated solutions depends largely on organizational size, operational complexity, and digital transformation maturity. Smaller operators with limited technical resources may benefit from off-premises monitoring services that provide expert diagnostic support without requiring internal expertise development.

Larger organizations with established enterprise data management infrastructure can leverage on-premises solutions that integrate monitoring data with operational parameters for enhanced diagnostic capabilities. These implementations enable correlation analysis between vibration signatures and process conditions, supporting more accurate fault detection and predictive maintenance planning.

Machine protection requirements also influence architecture decisions, as protection functions cannot be provided through remote services and require on-premises hardware implementations. Organizations requiring both monitoring and protection capabilities must implement hybrid solutions that maintain critical protection functions locally while leveraging remote diagnostic services for enhanced analysis capabilities.

Future Outlook

The digital transformation of hydropower condition monitoring continues to evolve as technologies advance and operational requirements become increasingly sophisticated. The integration of artificial intelligence, machine learning, and advanced analytics capabilities promises further improvements in fault detection accuracy, diagnostic reliability, and maintenance optimization.

Enterprise data management systems will continue expanding their role in hydropower operations, eliminating limitations associated with proprietary standalone systems while enhancing efficiency and reliability through comprehensive data integration. Third-party service providers will gain enhanced access to cybersecure data for transparent analytics, including thermodynamic performance calculations and specialized diagnostic services.

The industry’s commitment to digital transformation positions condition monitoring as a critical enabler of operational excellence, safety enhancement, and cost optimization. Organizations that embrace comprehensive monitoring strategies supported by advanced data management capabilities will achieve competitive advantages through improved asset utilization, reduced maintenance costs, and enhanced operational reliability.

As global energy demands continue rising and grid systems become increasingly complex, hydropower operators must leverage every available technology to optimize performance while maintaining safety and reliability standards. Digital condition monitoring solutions provide the foundation for achieving these objectives through data-driven operational excellence that protects both equipment investments and revenue streams.

—Mike Hastings is a senior application engineer and Jon Fox is a senior product manager with B&K Vibro.