Partial wind project repowering enables owners to generate more energy from their sites, extend the life and improve the availability of their projects, and take advantage of extended renewable energy production tax credits. Partial repowering was implemented at dozens of sites in 2017 and 2018, and is expected to be widely implemented in 2019 and 2020.

As the global fleet of wind power projects continues to grow and age, and with significant improvements to turbine technology in the past decade, repowering is increasingly prevalent. In the past several years, partial repowering of wind projects has become an attractive option for many wind project owners in the U.S. in large part because of tax law changes enacted in December 2015 and the availability of repowering offerings from wind turbine suppliers.

This article highlights best practices, common challenges, and insights Sargent & Lundy has identified in recent wind repowering efforts, with a focus on wind turbine foundations, electrical balance-of-plant (BOP), and wind turbine towers. Our goal is to inform project owners, investors, lenders, and engineers about current and future repowering projects.

Our findings are based on Sargent & Lundy’s experience with 35 wind project repowerings in the past two years. Our role on many of these projects was to serve as the independent engineer, typically in support of tax-equity financing. Our work includes inspections of more than 2,600 wind turbine foundations, structural analyses of six different types of wind turbine foundation designs, more than 110 tower inspections, reviews and analyses of numerous electrical BOP systems, and a variety of other commercial, financial, and permitting reviews.

There are several critical considerations when determining whether a wind project is a strong candidate for partial repowering, such as the integrity and capacity of the turbine foundations, the impact of repowering on the plant electrical systems, and the condition of the wind turbine towers. Other important considerations include understanding the energy yield of the repowered wind project, the suitability of the repowered wind turbines for the site, long-term operations and maintenance (O&M) costs, and commercial and permitting impacts. To address these key considerations, Sargent & Lundy developed a carefully considered methodology founded on thousands of hours of analysis from recent wind repowering projects, as well as our industry-leading depth of structural and electrical engineering experience.

Renewable Energy Production Tax Credit

In December 2015, the U.S. Internal Revenue Service (IRS) extended the renewable energy production tax credit (PTC) program. Wind facilities that commenced construction by December 31, 2016, are eligible for the full inflation-adjusted per-kilowatt-hour credit for 10 years from the date they are put into service. Thereafter, PTCs are reduced by 20% for projects beginning construction in 2017, 40% for projects beginning construction in 2018, and 60% for projects beginning construction in 2019. The tax credit applies to both new construction and repowering projects that satisfy the 80/20 rule.

The 80/20 rule, as defined by the IRS, dictates that a “facility may qualify as originally placed in service even though it contains some used property, provided the fair market value of the used property is not more than 20% of the facility’s total value.” In other words, the cost of new components divided by the value of the repowered facility must be greater than or equal to 80%. To ensure a repowering effort meets IRS guidelines, typically two or more independent consultants are hired to perform valuations of the retained components and calculate if the 80/20 criteria can be met. All the partial repowering projects Sargent & Lundy has been or is involved with were able to meet (or plan to meet) the criteria set forth by the IRS to claim the PTC while utilizing, at a minimum, existing wind turbine foundations, wind turbine towers, and electrical BOP.

To date, Sargent & Lundy has experience with partial repowering projects that cover a range of part replacement strategies. Some projects have chosen to reuse yaw systems, nacelles, and generators, while replacing components like blades, hubs, main shafts, main bearings, and gearboxes. Other projects have gone further and replaced all major components above the towers, including blades, generators, yaw systems, and nacelles. Yet another partial repowering variation is the complete replacement of up-tower components of one manufacturer with newer technology from a different manufacturer while retaining the existing towers and foundations.

Key Considerations for Partial Repowering

A selection of Sargent & Lundy’s key considerations for wind project repowerings are highlighted below and include findings to aid owners, investors, lenders, and engineers with maintaining ongoing operations and planning for successful repowering.

Wind Turbine Foundations. Integrity and capacity of existing foundations are the most critical considerations for the long-term success of a partial repowering effort. In particular, owners and tax-equity investors have rightly insisted upon a thorough, detailed and comprehensive review of existing foundations, including strength, serviceability, and fatigue analyses.

Sargent & Lundy has established an approach to understand the risk of foundation failure based on thousands of hours of analysis on repowering projects. Key discoveries and outcomes from the extensive modeling we have performed for a variety of wind turbine foundation designs—including octagon spread footing, circular spread footing, foundation mounting part (FMP) spread footing, soil/rock anchor, and Patrick & Henderson (P&H) Tensionless Pier—are discussed below, including the methodology established to assess the risk of foundation failure.

Sargent & Lundy’s approach for determining the risk of wind turbine foundation failure begins with a review of the original foundation design and, in particular, whether the design was developed with proper consideration for fatigue loading. The firm also assesses the condition of the exposed, that is, above-grade, portion of foundations. Additionally, excavation at a statistically relevant sampling of wind turbines is typically performed in advance of the repowering effort to check for cracks and assess the general condition of the buried portions of the foundations.

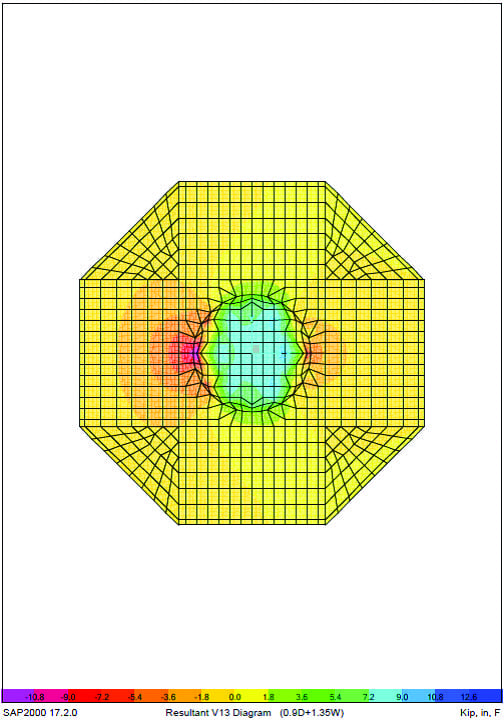

Following a site visit, the firm reviews a project’s quality assurance and quality control (QA/QC) documentation to assess the quality of workmanship, and adherence to wind turbine and foundation design specifications from initial construction. While this review can be a challenge for plants that have changed ownership or have poorly managed document control, Sargent & Lundy uses available information and statistical methods to develop analysis input parameters. Finally, and most importantly, Sargent & Lundy develops a detailed finite element analysis (FEA) of the foundation design to properly assess its strength, serviceability, and fatigue (Figure 1).

|

|

1. Finite element model of repowered spread footing foundation. Courtesy: Sargent & Lundy |

Electrical Balance-of-Plant. Reusing the electrical BOP components and systems can provide substantial cost savings but is not without risk to a repowering project. To assess such risk, an evaluation should be performed to gauge the suitability of the existing electrical BOP for the repowered wind turbines and the impact of additional years of operating life on the equipment. Evaluations should include a detailed analysis of site drawings, calculations, and relevant reports, along with a site visit to ensure the substation, collection system, control systems, and transmission lines are suitable for repowering (Figure 2).

|

|

2. A Sargent & Lundy engineer performs a site visit to observe the condition of the balance of plant at a partial repowering candidate site. Courtesy: Sargent & Lundy |

Certain partial repowering variations, including those that involve changes to the turbine maximum output, generator, reactive capability, or transformer ratings, may require new engineering studies to support the repowering. For example, studies may need to be completed for ampacity, transformer loading, reactive capability, short circuit, grounding, relay coordination, harmonics, and supervisory control and data acquisition (SCADA) coordination. The results of these studies may require new capital upgrades, replacements, or site-specific curtailments to ensure the reliable operation and compliance of the electrical BOP post-repowering.

Wind Turbine Towers. Partial repowering efforts to date in the U.S. have elected to reuse existing wind turbine towers. In general, the towers Sargent & Lundy observed at repowering candidate sites (ranging from nine to 18 years old) have been in good condition and considered suitable for repowering. However, there have been projects where towers have sustained damage or failed in the past, making it important to assess the condition of the towers both externally and internally via tower climbs to ensure that the towers are in good condition and properly maintained.

In addition, documentation including analyses and certifications of the repowered turbines, pre-upgrade (that is, pre-repower) inspection certificates, and existing procedures and maintenance records should be reviewed. Our findings from tower reviews have been largely site-specific and typically don’t require large capital expenditures.

Wind Resource Assessment. Performing a wind resource assessment based on a repowered configuration reduces the uncertainty of a project’s forecasted power generation and associated revenue. As a part of the assessment, the increase in gross energy production on an annual basis and, in some cases, a monthly basis can be determined using existing and proposed power curves, and a best estimate of wind frequency distribution. In general, a wind resource assessment should include an uncertainty analysis, including P50, P75, P90, P95, and P99 estimates of net energy for use in a project’s financial models.

While repowering efforts typically involve replacing existing blades with longer blades able to capture more energy from the wind, these may also result in increased wake losses and wake-induced turbulence. For this reason, appropriate wind resource assessment software should be used to establish differences in wake losses between the original and repowered turbine configurations. A thorough wind resource assessment of a repowered site should provide an accurate prediction of power generation with more certainty than a project’s original pre-construction assessment, due to the additional wind data available from years of operating the wind power plant.

Wind Turbine Technology and Site Suitability Review. A review of the planned repowered technology should be performed to assess potential implications of the combination of existing components and new components. An example of this is whether a project’s existing yaw drives can handle higher loads from a new larger rotor. Industry experience with primary replacement components should be reviewed to identify potential issues that may result from the combined use of existing and new equipment. Then, the wind turbine manufacturer’s approach to resolving any problems should be assessed.

The review should also consider sequencing effects of wear and fatigue damage on components that are not planned to be replaced. This review is especially important when the original wind turbines from one manufacturer are being partially repowered with new components from a different wind turbine manufacturer.

Commercial and Permitting Review. Prior to repowering, a review of commercial agreements and permitting requirements should determine that operating and technical requirements of applicable agreements and contracts will be met post-repowering. The review should include existing approvals, permits, and licenses to confirm a repowered plant can operate in full compliance and there are no limiting restrictions after the commercial operation date.

Extending the life of a wind power plant through partial repowering typically pushes the anticipated project life past the expiration dates of important contracts, such as power purchase agreements. Sargent & Lundy recommends that appropriate sensitivity cases be considered in any financial models when projecting revenue beyond the expiration date of such contracts. It is important to rely on experienced industry professionals to identify the appropriate sensitivities and risks.

To reduce the risk of non-compliance for repowering on which a generating capacity increase is planned, the interconnection agreement should be reviewed in detail. Several federal legal authorities, including the Federal Aviation Administration, U.S. Army Corps of Engineers, U.S. Fish and Wildlife Service, U.S. Environmental Protection Agency, and state and county legal authorities may impose additional permitting requirements to consider. Consult a permitting specialist with relevant experience to avoid unexpected delays and/or fines. During recent repowering projects, Sargent & Lundy has performed the permitting review alongside the commercial review.

Operations and Maintenance Cost Assessment. Projected O&M costs following repowering through the end of a project’s life should be estimated and, if appropriate, compared with values in any relevant financial models to evaluate the level of risk to project stakeholders. This assessment should include a review of existing operations, maintenance, and management agreements in place; a review of historical operating costs for a project; and an assessment of O&M cost escalation for similar operating wind projects. The review should also include assessments of unplanned maintenance caps relative to historical major component failure rates.

A buildup of anticipated annual project costs can be calculated based on a review of operating cost data gathered from similar projects. To gather this data, Sargent & Lundy relies on an internal O&M project cost and performance database that includes cataloged capital cost, operating cost, and performance data from more than 250 wind projects.

Generate More Energy and Extend Project Life. Project owners can benefit from partial repowering by generating more energy, extending the life of their projects, and improving the availability of their projects—all while making the most of extended renewable energy PTCs. There are many important factors to consider prior to undergoing a partial repowering project; however, the integrity and capacity of a project’s existing wind turbine foundations is the most critical.

|

|

3. Successful repowering projects require extensive analysis conducted by highly skilled engineers. Courtesy: Sargent & Lundy |

Sargent & Lundy has developed a carefully considered methodology founded on thousands of hours of analysis across recent wind repowering projects and industry-leading depth of structural and electrical engineering experience (Figure 3). The firm’s depth of structural experience is the result of a highly skilled staff comprised of more than 200 structural engineers and more than 400 electrical engineers including many with PhDs and/or other advanced degrees. Sargent & Lundy’s staff fills more than 220 positions on industry code committees including ACI 351 (Rotating Equipment Foundations), AISC TC9 (Seismic), ASCE (Turbine Foundations), and ACI 307 (Shrinkage Compensating Concrete – Past, Present and Future) among others.

Sargent & Lundy’s wind project partial repowering approach has withstood rigorous debate and numerous rounds of industry review. To further mitigate the risk of repowering, the firm has developed and implemented wind project electrical BOP and tower review processes that yield value in reduced risk to stakeholders while facilitating smooth repowering campaigns. Owners, investors, lenders, and engineers are encouraged to leverage the experience and findings shared in this article to achieve a more-efficient, well-informed repowering campaign. ■

—Eric DeCristofaro is a senior energy consultant with Sargent & Lundy, Eric Soderlund is a senior manager with Sargent & Lundy, and Matthew Thibodeau is a vice president and project director in Sargent & Lundy’s energy consulting group.