Fast neutron reactor systems have the potential to extract 60 times more energy from uranium compared to existing thermal reactors, and they contribute to a significant reduction in the burden of radioactive waste. Wide progress has been made of late in many countries that are actively developing the reactors and related fuel-cycle technologies.

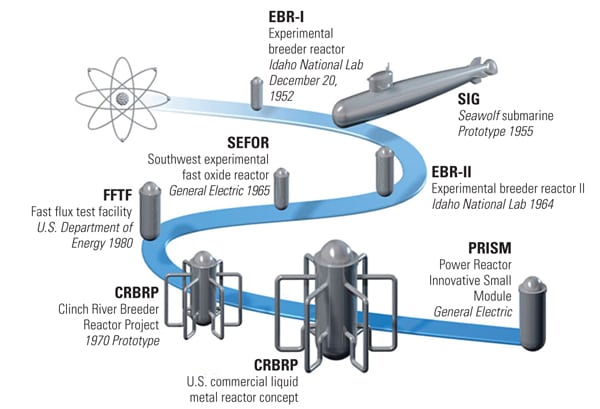

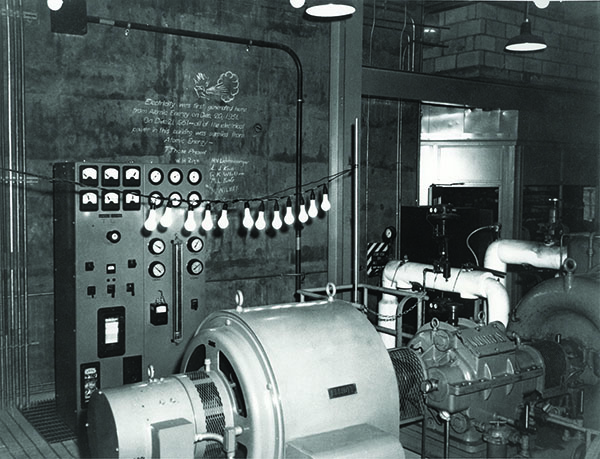

It was a liquid metal–cooled fast-neutron reactor that illuminated—with the flash of four lightbulbs—the possibility that our world could be powered by nuclear energy. But though that pioneering moment on Dec. 20, 1951, at Argonne National Laboratory’s Experimental Breeder Reactor I (EBR I) in Idaho, spawned countless breakthroughs that exponentially expanded the realm of nuclear power technology, fast-neutron reactors have remained commercially elusive.

|

|

1. Experimental Breeder Reactor I (EBR I) ushered in a new era when it became the first reactor to generate useable amounts of electricity from nuclear energy. It accomplished this feat on Dec. 20, 1951, by lighting four light bulbs. The next day, EBR I’s output was boosted, and from that point until its decommissioning in 1964, EBR I often generated all of the electricity needed to power its building. Source: Argonne National Laboratory |

In the decades that followed the Argonne breakthrough (Figure 1), the concept that a nuclear reactor could “breed” more fuel than it consumed rapidly became a mainstay subject of national research adopted by a handful of other countries, including the Soviet Union, the UK, France, Germany, Japan, and India. Yet to date, only about 20 fast reactors have operated, some since the 1950s, and only one has operated in a commercial capacity—France’s 1,250-MWe commercial prototype Superphenix, which ran from 1985 to 1998, when it was closed on political grounds.

More recently, however, owing to technical advancements and growing operational experience, interest in fast reactor technology appears to have been piqued again. At the end of 2016, Russia put online the BN-800 at its Beloyarsk nuclear plant (a POWER Top Plant winner in November 2016), a project widely deemed the “most-powerful fast-breeder reactor in the world.” At least 16 other fast reactor projects are inching closer to deployment spearheaded by the U.S., France, Belgium, Romania, Russia, China, South Korea, India, and Japan. Two of these projects—Russia’s BN-1200 and China’s CDFBR-1200—could be commercial projects when they come online by 2030.

Meanwhile, today the world is grappling with concerns about nuclear waste with more urgency that ever before; after years of political haranguing, little progress has been made in storage and disposal of spent fuel. Argonne predicts: “Although there are currently very few [fast reactors] operating, they will ultimately prove vital to extending the world’s uranium and thorium energy supplies to tens of thousands of years and to removing the long-lived radiotoxicity from used nuclear fuel.”

Fast Reactors: A Different Breed

As Argonne explains it, when an atom in a nuclear reactor “fissions”—or splits into several smaller fragments—neutrons are released at high energy (fast speeds). In thermal reactors, which comprise the bulk of the world’s nuclear power fleet, the fission neutrons are slowed down to low (thermal) energies by collisions with light atoms within the reactor—hydrogen in the water in water-cooled reactors, deuterium in heavy water in heavy water–cooled reactors, or carbon in the graphite in gas-cooled reactors. Most of the neutrons in these reactors slow down to low speeds before they have a chance to cause subsequent fissions by colliding with fissile nuclei—which is usually uranium-235 (U-235).

“In a fast reactor, however, the fission neutrons are not slowed down and instead cause fissions by colliding with fissile nuclei at high energy,” the lab said. “This is important because more neutrons are released from fissions caused by high-energy neutrons than from fissions caused by thermal neutrons.” Although each fission reaction in a reactor destroys one fissile atom, fissile atoms can also be created when a neutron is captured in a reaction with a fertile atom, usually U-238.”

Essentially, the lab explains, in a fast breeder reactor, extra U-238 is added so that more fissile atoms are created than are destroyed by fission. “This means that essentially all of the original uranium ore (which is 99.3% U-238 and 0.7% U-235) can be used as reactor fuel in a fast breeder reactor. In contrast, only approximately 1% of the original uranium is consumed in a thermal reactor.” The effect, it noted, is that a fast reactor could extend the world’s uranium resources by a factor of about 60.

A second, more significant benefit, is that fast reactors “can destroy, by fission, the materials (plutonium, americium, curium, etc.) that make used nuclear fuel radioactive for longer than hundreds of years,” Argonne said. “These elements fission quite well when they collide with fast neutrons, whereas they fission far less or not at all when they collide with thermal neutrons. Thus, these materials operate as fuel in fast reactors, instead of functioning as waste products, as they do in thermal reactors. This feature of fast reactors makes the used fuel disposal problem far simpler by using the longest half-life parts of the waste as an energy resource.”

The Wide Array of Technologies Under Development

According to the International Atomic Energy Agency (IAEA), the potential boost that fast reactor systems operating in a fully closed cycle offer to nuclear fuel efficiency and waste management—and their implications for sustainability—is widely recognized, and active development continues in many countries on reactor, coolant, fuel, and fuel-cycle technologies. At a June 2017 conference that the agency hosted for the world’s fast reactor and related fuel-cycle community in Russia (the proceedings of which were released last December), a vast array of demonstration projects, ranging from small to large-scale, were reported to be under study, design, and construction.

As Subhash Chandra Chetal, a former head of India’s Indira Gandhi Centre for Atomic Research, told attendees in his opening speech, the variety of research is dizzying. “The fast reactor community is well aware that there is no perfect coolant for fast reactors and the choice gets deliberated from time to time both within the individual countries as well as in international forums.” The Generation IV International Forum (GIF), an association founded in 2000 to advance nuclear energy into its fourth generation, today has 14 member-countries and has distilled nearly 100 existing concepts into four fast-neutron spectrum categories that it says offer “the most promise.”

|

|

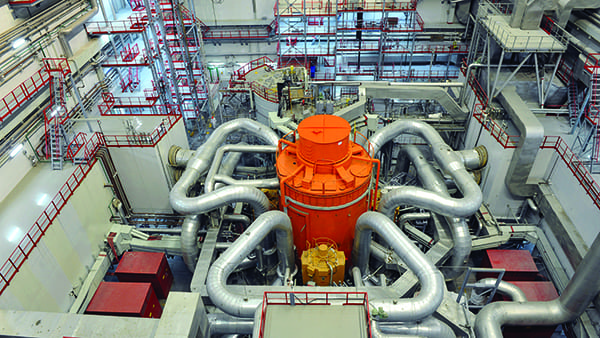

2. Pivotal to Russia’s “PRORYV”—or “Breakthrough”—program was construction of a BN-800 fast reactor designed by Rosatom’s nuclear engineering arm OKBM Afrikantov, which finally kicked off as the fourth unit at Beloyarsk in 2006. The unit began operating in December 2016. Courtesy: Rosatom |

Sodium-Cooled Fast Reactor (SFR) with a Closed Fuel Cycle. The most mature of all concepts, 20 SFR prototypes or demonstrations have been built throughout the world, which have provided more than 400 reactor-years of operation. Examples include BN-800 at Beloyarsk 4 (Figure 2) in Russia, India’s FBTR, France’s SuperPhenix, and the EBR I and II in the U.S. A number of private companies, such as GE Hitachi and TerraPower, have also shown interest in SFR.

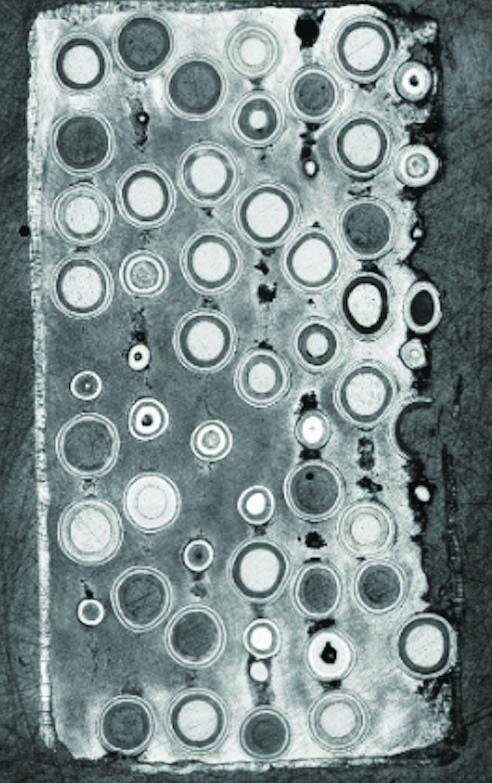

“Very valuable operating experience has been accumulated from the operating fast reactors as a feedback for future design in terms of both worth retaining and discarding for future designs in terms of materials, design options and sodium technology,” Chetal noted. Recent testing of mixed-oxide metal and carbide fuel have shown “excellent results,” and fuel burnup has been increased systematically with improvement in core structural materials. Meanwhile, “The causes of sodium leaks in different reactors due to design inadequacy in detailing the design, manufacturing deficiency, materials of construction and thermal striping are fairly well understood and are getting incorporated in future designs.” However, “A serious concern is still felt in some countries concerning sodium leaks, and double-wall piping in secondary circuits is selected to avoid sodium fire by a few designers,” he said.

Lead-Cooled Fast Reactor (LFR) with a Closed-Fuel Cycle. LFRs are cooled by molten lead (or lead-based alloys), which is offers no rapid reactions with water and air as with SFRs. LFRs operate at high temperature and at near atmospheric pressure, conditions enabled because of the very high boiling point of the coolant (up to 1743C) and its low vapor pressure. The coolant is either pure lead or an alloy of lead, most commonly the eutectic mixture of lead and bismuth, also known as LBE. Examples include the 600-MW European large power reactor, and Russia’s BREST-300, and a microreactor, SSTAR, which features a very long core lifetime. Private companies like Westinghouse, Hydromine, or LeadCold, have also developed basic LFR designs.

Gas-Cooled Fast Reactor (GFR) with a Closed Fuel Cycle. GFRs, which are cooled by helium, are proposed as a longer-term alternative to SFRs. GIF highlighted the innovative nuclear system’s several attractive features. It uses “a single-phase coolant that is chemically inert, which does not dissociate or become activated, is transparent and while the coolant void coefficient is still positive, it is small and dominated by Doppler feedback,” it said. Meanwhile, the reactor core has a relatively high power density, and offers improved inspection and simplified coolant handling. Its high core outlet temperatures are above 750F, but that “places onerous demands on the capability of the fuel to operate continuously with the high power density necessary for good neutron economics in a fast reactor core,” it said, a disadvantage that will require robust fuel and structural needs. Among private GFR systems is General Atomics’ EM 2 project. Still, according to GIF, the GFR concept is still in the viability phase and many not enter the performance phase before 2022.

Molten Salt Reactor (MSR) with Thermal and Fast Neutron Concepts with a Closed Fuel Cycle. A concept developed in the 1950s, the concept uses molten salt both as fuel and coolant, and graphite as a moderator. According to GIF, these types of liquid-fueled reactors have key advantages over solid-fueled systems. These include, “The possibility of fuel composition (fertile/fissile) adjustment and fuel reprocessing without shutting down the reactor; the possibility of overcoming the difficulties of solid fuel fabrication/re-fabrication with large amounts of transuranic elements (TRUs); the potential for better resource utilization by achieving high fuel burnups (with TRUs remaining in the liquid fuel to undergo fission or transmutation to a fissile element).” Fast spectrum MSRs offer the best of fast reactor and molten salt technologies, including extended resource utilization and waste minimization, as well as low pressure, high boiling temperature, and optical transparency, it said.

Examples include the 1,400-MWe MSFR developed by France within the SMOFAR project, which has a thorium fuel cycle, and Russia’s 1,000-MWe MOSART project. China is also investigating a fluoride salt–cooled high-temperature reactor, and a thorium molten fluoride salt-thermal reactor. The private sector, meanwhile, has launched several projects worldwide. Among companies of note are TerraPower, Thorcon, Terrestrial Energy, Flibe Energy, Transatomic Power, Elysium Industries, Alpha Tech Research Corp., and Kairos Power.

GIF also noted, however, that research and development challenges are numerous. “For the liquid-fuel option with closed-fuel cycle, they are dealing with the salt properties (physical, chemical and thermodynamic properties) and solubility of actinides and fission products in the salt; system design and safety analysis (including development of advanced neutronic and thermal-hydraulic coupling models); development of advanced materials (including studies on their compatibility with molten salts and behaviour under high neutron fluxes at high temperature); corrosion and tritium release prevention based on proper molten salt Redox control; development of efficient techniques of gaseous fission products extraction from the fuel salt by helium bubbling; fuel salt processing flowsheet (including reductive extraction tests for actinide/lanthanide separation); and development of a safety-security approach (and proliferation resistance) dedicated to liquid-fueled reactors.” The concept is still in a feasibility or viability phase, and the performance phase may not begin until 2025, it noted.

The Quest for Better Economics

While the proceedings showed general optimism about the future of fast reactors, several speakers recognized challenges that could hamper the progress of fast reactors. The IAEA said, for example, “To achieve the full potential of fast neutron reactors, reaching a real breakthrough in the utilization of nuclear energy, the research and technology developments will have to demonstrate the fulfillment of modern criteria of economic competitiveness, stringent safety and security requirements, sustainable development, proliferation resistance and public acceptance.”

According to Chetal, the quest for better economics is hampered by a dearth of information because only SFRs have so far been built for demonstration and commercial purposes. “The technology viability of SFRs has been well-demonstrated in experimental and demonstration reactors. However, the economic competitiveness of SFR has not been well-proved yet,” he noted. “The perceived higher cost of SFRs compared with [light water reactors (LWRs)] has impeded its growth. The economic comparison of SFR versus LWR has strong linkages with the [low] cost of uranium, which presently puts pressure on SFRs to look for ways and means to improve on capital cost, construction time, and capacity factor,” he said.

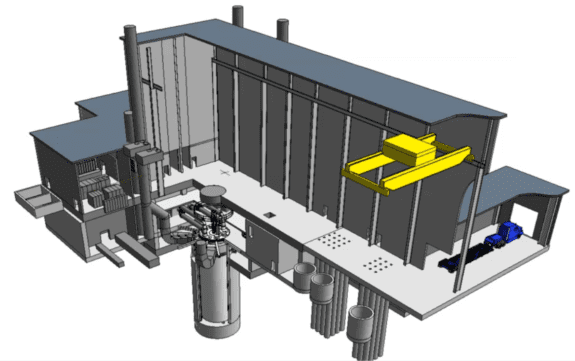

Substantial improvements already may have been made for some Russian fast reactor projects, suggested E.O. Adamov, an expert with Rosatom’s PRORYV project. The federal project has, since 2012, sought to create a technological base for wide-scale fast reactor use using knowledge gained from operation of the BN-800 at Beloyarsk 4. To date, the BN-600, a 1981-built fast reactor (Beloyarsk 3), has been found to be economically comparable to Russian VVER technology, if it can be scaled up. Adamov said Russia is now looking to prove that the BN-1200 that is under development—and differs significantly from preceding BN models—can compete with “the best nuclear plants on thermal neutrons.” A comparison between the levelized cost of energy for fast reactors and combined cycle gas turbine (CCGT) power plants under Russian conditions have yielded key insights, he noted. One is that nuclear power plants with thermal reactors with an open fuel cycle “cannot guarantee the further efficient competitive development.” If established performance requirements for BN-1200 facilities are achieved, however, fast reactors could easily compete than CCGTs, and even renewable sources, he said.

India, which is in the process of commissioning a much-delayed 500-MW prototype fast-breeder reactor (PFBR) at Kalpakkam in Tamil Nadu, has meanwhile recognized that the cost of reprocessing plants will be important to the future of fast reactors. The “Indian assessment shows that it is prudent to co-locate the fast reactor fuel cycle facility for reprocessing and refabrication at the same site as the reactor and should be designed for multiple reactors,” Chetal said. “In light of this, a fast reactor fuel cycle facility is under construction at the site of PFBR to reprocess and refabricate the [mixed oxide (MOX)] fuel elements for PFBR and two more MOX reactors of 600 MW each.”

Other Hurdles Slowing Fast Reactors

First-of-their-kind fast reactors also face the cumbersome challenge of obtaining timely licensing. As several speakers at the IAEA conference noted, few experts within regulatory environments are well-versed in fast reactor challenges. A lack of technical expertise needed to manufacture components for fast reactor facilities, as well as to build, commission, operate, maintain, and decommission them is as critical.

Addressing safety issues concerning the wide array of systems under development are also crucial. But much research has been ongoing on this front, too, specifically relating to SFRs. In Japan, for example, researchers are studying risks through assessment methodology. China has established a safety code for nominal conditions based on SFR parameters for decay heat and sodium concrete interactions. ASTRID, a demonstration SFR project that France is developing in collaboration with Japan, has yielded a safety design guide with basic principles. Russia’s safety assessment of the BN-1200, meanwhile, identified three types of beyond-design accidents: the loss of power (where pumps in the primary and secondary circuits stop and there is no water supply feed); the introduction of reactivity by withdrawing of two control rods; and a fuel assembly blockage accident).

Overarching all these efforts is an increasingly intricate network of international cooperation to foster information sharing on research and development, and technical expertise. Along with GIF, the IAEA coordinates the 2000-established International Project on Innovative Nuclear Reactors and Fuel Cycles. Meanwhile, the European Sustainable Nuclear Industrial Initiative is developing ASTRID in France, ALFRED, an LFR in Romania, and MYRRHA, which is a lead bismuth irradiation project in Belgium. ■

—Sonal Patel is a POWER associate editor.