With a broadening portfolio of generation technologies and rapidly changing demands, effectively combining and integrating diverse technologies is important to a reliable power grid. Siemens’ SIESTART solution—a combination of battery technology and a simple or combined cycle Flex-Plant—results in an integrated power plant that reacts instantaneously to complement weather-dependent renewable generation.

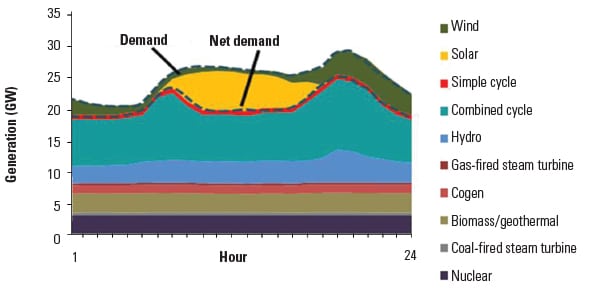

The energy landscape has changed dramatically over the past several years. Renewable generation plays a larger role in today’s market, and that role continues to expand. In an ideal world, renewables would produce exactly the amount of power demanded at exactly the time it was needed, but that turns out to be the exception rather than the rule. Thus, the weather and time of day is more influential than ever in the power generation industry.

On a typical day, solar generation is highest around midday, but it can vary dramatically based on conditions. Wind power is often highest in the evening or overnight, but it too is highly dependent on location and conditions. In most markets, the highest power demand is often in the afternoon and evening timeframe. In other words, power demand typically peaks when solar power is coming offline and wind power hasn’t ramped up yet.

High solar production or strong winds at night can (and often do) generate more power than the grid demands, leading to low or negative power pricing during certain times of the day or night. This time shift between power production and grid loading means other generation has to be used to match the supply with the demand so that exactly the right amount of electricity is delivered when needed.

There are a number of solutions available in the market to address undersupply of electricity. Rapid demand increases can be addressed efficiently by today’s fast-start and fast-ramp technologies like Siemens’ Flex-Plant combined cycle units. Siemens’ SIESTORAGE battery storage system addresses the challenge of over generation, taking surplus power and storing that energy in a battery. SIESTART integrates these two technologies, resulting in a solution that is more capable and flexible than either technology on its own.

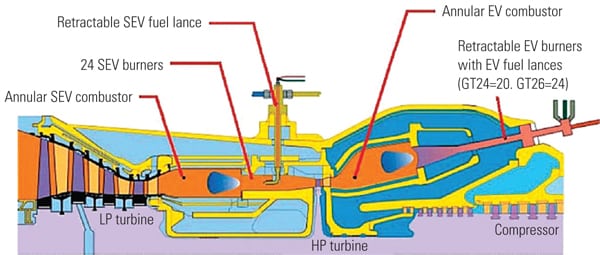

Flex-Plant Gas-Powered Generation

All power generation technologies have associated strengths and weaknesses. In the case of gas turbine power plants, strengths include:

■ Dispatchability. Both simple and combined cycle plants can be called upon by grid operators or plant owners to run at any time.

■ Reliability. Gas turbines are dependable machines, with reliabilities frequently measured to be greater than 98%.

■ Continuity. Gas turbine power plants can be started and run for extended periods of time either as baseload or peaking units.

Finding the right technology to couple with gas turbine power plants requires improving or eliminating the major weaknesses of the technology, namely:

■ Instantaneous. Gas turbine power plants can start very fast—some Flex-Plants can reach baseload in less than 30 minutes and simple cycle plants in under 10 minutes—but they cannot achieve an instantaneous start to full power.

■ Blackstart. Gas turbines require power for initial startup. This can come from the grid or from an on-site blackstart generator, which is typically a lower efficiency and less environmentally friendly technology like a reciprocating engine.

■ Power balancing. Gas turbines can ramp up and down very quickly, but can’t take full advantage of negative power pricing, demand response, or power consumption.

SIESTORAGE

The concept of an energy storage system is simple; store power when there is a surplus, and then provide power to the grid when there is a demand. There are a few different technologies available in the market that operate in this capacity, but one of the most common is a battery storage system like Siemens’ SIESTORAGE.

Some of the strengths associated with a SIESTORAGE system are:

■ Instantaneous. Power can be supplied to the grid (or load) in less than one second.

■ Power balancing. Batteries are bidirectional, providing power to the grid when needed and absorbing power from the grid when it’s not.

■ Emissions. Batteries discharge electricity with zero emissions.

While it is becoming more common to co-locate battery storage solutions at renewable sites to help alleviate the intermittency issue, the resulting power plant is still unreliable. The batteries can store surplus power, but when the batteries are depleted and the source (sun or wind) is still absent the power plant production drops to zero.

SIESTART

An opportunity for innovation arises when you can combine multiple technologies and mitigate or eliminate one’s weakness with another’s strength. SIESTART combines the strengths of a gas turbine power plant with the strengths of a battery storage system.

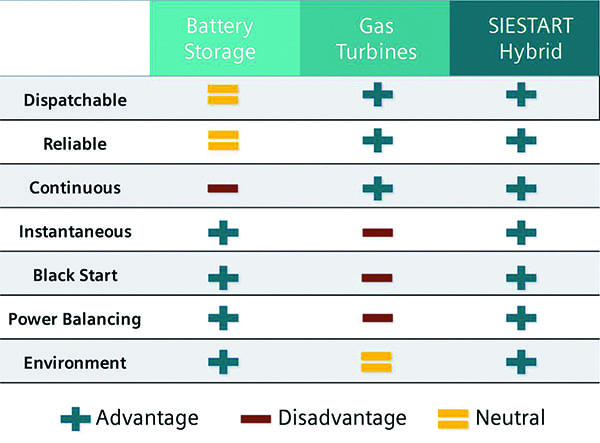

Comparing the system characteristics side-by-side (Figure 1) shows the complementary relationship of battery storage systems and gas turbine power plants. SIESTART delivers the best of both technologies in one facility—and enhances the strengths when they are combined.

|

| 1. SIESTART advantages. The operational benefits of a hybrid system that combines battery storage with gas turbine technology are substantial. Courtesy: Siemens |

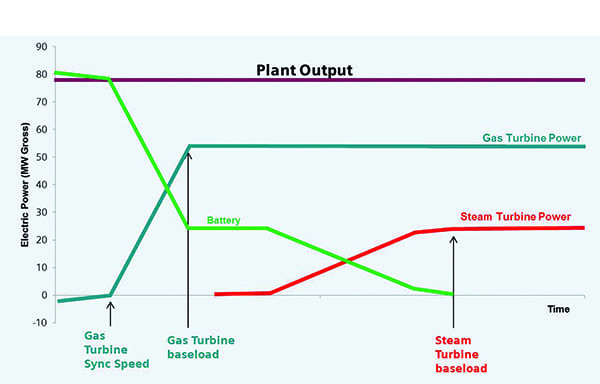

To demonstrate the full potential of a SIESTART system, consider the following example. A 1 x 1 combined cycle power plant with a nominal 80-MW output is fully deenergized. A grid that relies on wind and solar power suddenly sees an unpredicted loss in renewable production. This creates a situation where electrical load is constant, but supply is rapidly decreasing.

To prevent brownouts and subsequent blackouts, the grid operator calls on the SIESTART plant for full output. In less than one second the full 80-MW supply is on the grid, stabilizing grid power. From the grid’s perspective, 80 MW is delivered and the crisis is averted.

Inside the power plant’s fence, the SIESTORAGE battery storage system immediately delivered 80 MW to the grid and provided the operators with time to analyze the situation. If renewable generation were to come rapidly back online, the batteries could be ramped down and deenergized, avoiding an unnecessary gas turbine startup. If the renewable generation didn’t return quickly, the batteries would continue to provide 80 MW to the grid, as well as power to startup the gas turbine. The gas turbine would then be started normally and ramped up to full output. As the gas turbine ramped up, battery output would decrease to keep a constant 80-MW delivery to the grid. As the steam turbine went through a normal startup and ramp to full load, the battery output would further be curtailed until the full 80 MW was delivered by the combined cycle plant (Figure 2). The plant could then operate in combined cycle mode until renewable supply increased or the demand subsided.

SIESTART Value Generation

In addition to the intrinsic benefits noted previously, SIESTART delivers additional benefits that are not possible with two separate solutions. These can often be monetized in different energy markets. For instance:

■ Spinning reserve. SIESTART can deliver the capacity of the batteries instantaneously, and that power can continue until the gas turbine power plant is up to full output. In other words, with proper sizing, full plant output can be delivered in less than one second, so full plant output can be offered as spinning reserve.

■ Arbitrage. SIESTART gives a plant the ability to consume power if the grid is in surplus, potentially making money off the energy consumption, then selling the energy back to the grid when demand increases and power prices become more lucrative.

■ Energy storage. Many localities offer credits, or even mandates, for energy storage systems. SIESTART (on a new unit or retrofit basis) can allow realization of those credits or satisfy storage requirements.

■ Blackstart. A SIESTART gas turbine plant can be designated as a full blackstart plant, allowing additional revenue and offsetting potentially inefficient reciprocating engine operations.

■ Peaking demand. Adding SIESTART to a gas turbine provides an extra “boost” of output from the batteries when the grid (or load) needs it the most, enabling the plant to take full advantage of high-value peak power.

■ Day-ahead market. SIESTART batteries can be used to provide additional power output on top of the gas turbine production. This power can be sold in the same manner as any other megawatts.

■ Real-time market. The output from a SIESTART power plant can be ramped up and down instantly to follow load or market prices.

■ Capacity market. SIESTART plant output (gas turbine power plant plus batteries) can be fully committed at any time, as the battery output is not time or weather dependent.

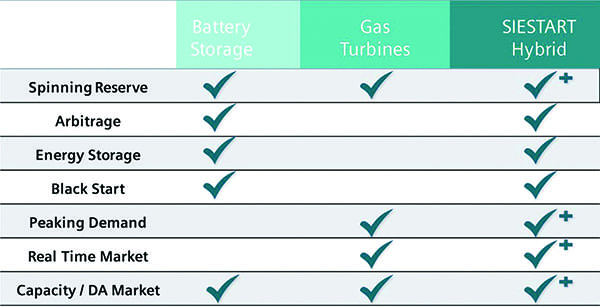

Market applicability is shown in Figure 3.

|

| 3. Taking advantage of the system. By combining battery storage with gas turbine technology, the SIESTART hybrid captures enhanced benefits. Courtesy: Siemens |

Beyond the Energy Market

Energy storage technologies have seen considerable advancements across the board, including thermal storage with chilling systems, mechanical storage with flywheels, pumped hydro, compressed air, and electrical storage with batteries. However, of all these technologies, the SIESTART solution could have the most profound impact on the industry.

SIESTART has applications far beyond the energy market, especially in places where responsiveness is measured in seconds rather than minutes. For critical loads, such as hospitals and data centers, SIESTART can deliver the instantaneous response of a battery with the reliability and durability of a gas turbine. Any size power plant (combined cycle or simple cycle), any model gas turbine, and any energy market (or power demand) could recognize the benefits of this solution.

As the price of resources change, environmental requirements evolve, and new technologies enter the market, the diversity of power generation supply and demand can be expected to broaden. The only constant throughout this change is that generators need to be as flexible as possible.

To enable the reliable, stable power generation grid that loads and customers require, solutions that effectively integrate diverse technologies and demands are critical. Siemens’ SIESTART portfolio, combining SIESTORAGE with a simple or combined cycle Flex-Plant, results in a power plant that is more capable and flexible than either solution alone. This allows owners to recognize benefits that have not been achievable with a single solution in the past, while capitalizing on value over a full range of demands for the future. With high baseload efficiency, fast load-change capability, and instantaneous response, SIESTART has redefined power plant flexibility. ■

—Chris Mieckowski is product line manager for North America with Siemens.