Coal, by its very nature, is a dusty fuel. That poses a serious risk at coal-fired power plants, because coal dust can be highly explosive. However, actions can be taken to reduce the risk. Implementing strict administrative controls is a good first step, but combining that with other passive and active control measures may be the best way to ensure a plant avoids catastrophe in the long run.

On February 7, 2008, the Imperial Sugar refinery in Port Wentworth, Ga., exploded, ultimately killing 14 people and injuring 38. The resulting investigation determined that the explosion was fueled by massive accumulations of combustible sugar dust throughout the packaging building at the plant.

After that incident, industrial facilities all over the U.S. took notice. Whether sugar, flour, wood, plastics, or coal, uncontrolled industrial dust is a significant explosion risk. Utilities with coal generation facilities, rightly concerned with the safety implications, worked to develop plans to mitigate the combustible dust risk at their coal-fired plants.

The concern was driven in part by the fact that many plants have converted from Appalachian coal to Powder River Basin (PRB) coal for its noteworthy environmental benefits. However, there is a significantly increased risk of dust explosions in these converted plants due to the possibility of spontaneous combustion and the higher explosive severity of PRB coal.

People who take safety seriously don’t wait around for regulations to change. They work to mitigate the risk of combustible dust disasters regardless of whether or not they are meeting present regulatory guidelines.

A good first step is to conduct an audit of the current combustible dust risk level at your coal-fired plants. That establishes a baseline for risk and helps management understand what is required to ensure safe operations. To improve working conditions and protect lives of employees, a plan for plant upgrades and a cost estimate for projects is needed.

Evaluating Problems

Acensium was brought in to perform an audit for a major southern utility’s coal plants in 2010. Acensium’s leadership had significant experience in PRB coal conversions and meaningful expertise in mitigating coal dust risks, which was a driving factor in the company’s selection. The utility assigned a corporate project manager to work with Acensium in planning the project and budgeting the upgrades over a 7-year period.

Together, the team performed onsite evaluations of each plant targeted for upgrades. Data was compiled on all problems identified at each plant, a technical plan to implement solutions was developed, and a budget was created to carry out the plan. The process culminated with a central meeting of all the coal-handling managers from each plant. The meeting lasted approximately two full 8-hour days.

At the client’s insistence, improvements were prioritized based on safety impact—not the revenue ranking of each plant. The outcome was $180 million in budgeted safety improvements designed to shrink the risk presented by coal dust in each unique situation. A schedule was developed to implement upgrades across the plants, and the program was launched in the spring of 2011.

Getting Coal Dust Under Control

The plan to effectively manage coal dust at each facility was comprised of three key components. The approach to dust management for material-handling systems followed a path from administrative controls, to passive engineering controls, and then to active engineering controls.

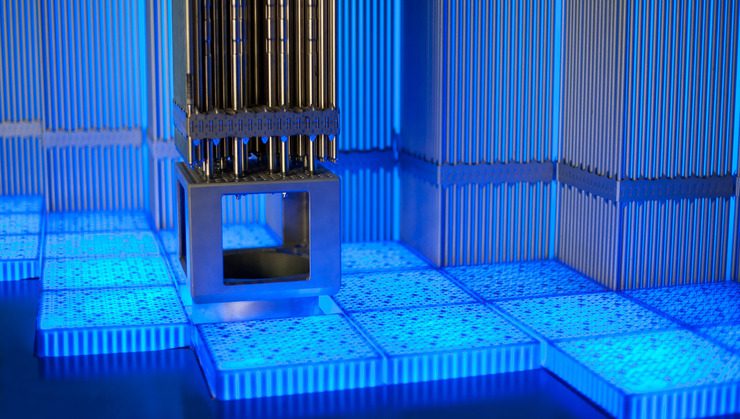

Administrative Dust Control. One of the initial priorities was to create a culture in the material-handling department in which the danger of combustible dust was understood, and simple, everyday actions were carried out to reduce that risk. Those actions included closing chute inspection hatches (Figure 1), closing doors to material handling buildings, and completing more frequent walkdowns during operation. Typically a large portion of combustible dust can be controlled through culture change and its ensuing positive actions.

|

| 1. Button it up. Little changes, like closing chute inspection hatches, can go a long way in reducing dust throughout a plant. Courtesy: Acensium |

Passive Dust Control. The second priority was to implement a foundational change in how the general material stream was handled at each plant. That included replacing end-of-life equipment in the transfer systems in order to capture nominal coal particles before moving on to containing submicron dust. Acensium informed the customer that transfer point technology had advanced significantly since most of the plants had been constructed, and that transfer point features and materials had been developed to allow better material control and prevent spillage, while extending maintenance intervals.

In the mid 1980s, Alan Huth first conceived a hood-and-spoon arrangement for material handling transfers. The concept of the hood was employed to consolidate the material flow as it left the delivery belt with a curved hood arrangement. The hood was constructed with curved or angled panels that closely followed the projected trajectory of the material (Figure 2). By following the trajectory of the material, impact could be reduced, or even eliminated. In addition, the hood had the effect of “squeezing” the air from the material, leaving a very dense material stream to pass through the chute, with little to no entrained air.

Located just above the receiving belt, at the bottom of the chute, the spoon performs a similar impact-reducing function. As the dense material stream from the hood travels to the receiving belt, the spoon presents a series of curved surfaces that ultimately discharges the material closer to the receiving belt. Some spoon designs claim to discharge the material not only close to the receiving belt, but also at the same velocity. When this is achieved, material flow on the receiving belt appears very settled, absent of the usual turbulence that tends to liberate coal dust on the receiving belt.

Power generation coal-handling operators began to specify stainless steel construction in the late 1990s. The initial surge in use of this material was correlated with excessive corrosion that many facilities experienced after the conversion to low-sulfur, Western coals. While more difficult to work with in the fabrication shop, and even more so in the field, stainless steel offered the advantage of providing a shell that could last as long as the new materials that were being used to line impact and sliding areas inside the chute.

Transfer point designs should seek to minimize impact within the coal chute. Impact is the major cause of liner degradation through direct material fracture (ceramic) or “washing” of the metal matrix (overlay products). In addition, impact leads to further fracturing of the coal, creating more coal dust with the potential for liberation from the system.

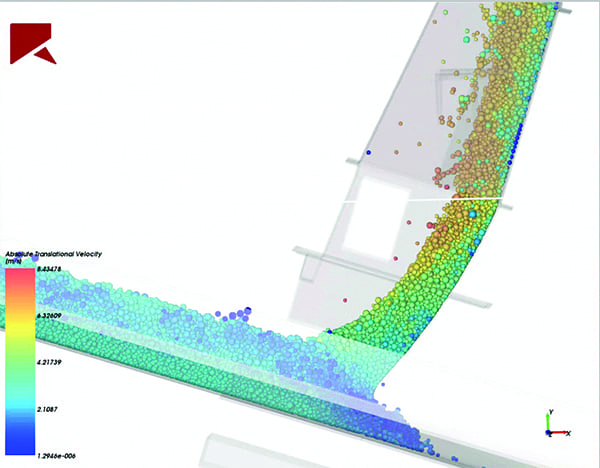

Utilizing computer-aided design tools (Figure 3) to create complex transfer chute geometries, particle velocity can be controlled, allowing a substantial reduction in the volume of airflow that is typically observed in conventional transfer systems. Further, engineering controls that utilize passive dust control help reduce operating and maintenance costs typically associated with active dust control.

|

| 3. Designing improvements. Computer-aided design tools can help engineers optimize transfer chute geometry to reduce dust creation. Courtesy: Acensium |

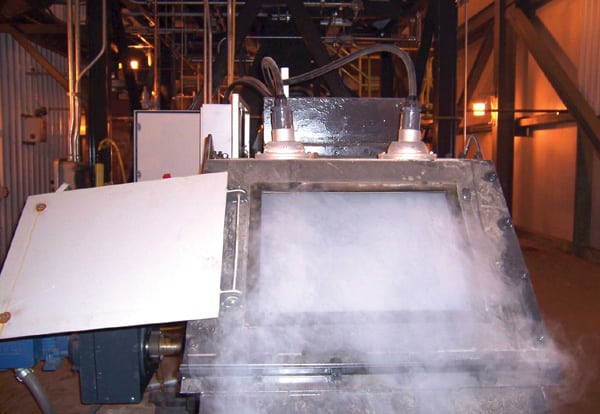

Active Dust Control. Active dust control includes suppression and collection of dust particles utilizing chemical surfactants and wet dust collection, respectively. During crushing and silo-fill operations, active collection is often required, because passive engineering controls are not able to contain an acceptable amount of fugitive combustible dust.

Coal dust collection systems, as applied to power generation coal-handling systems, should be referred to as “excess air collection systems.” Coal dust is a viable fuel for the boiler, if it can be safely conveyed there for combustion. Collecting dust from the conveyance stream only adds additional operational costs. Coal dust should be maintained on the conveyors and loaded safely into the silos.

Coal dust collection systems should be used to remove excess air from transfer systems. This excess air is typically a function of entrained, induced, displaced, or generated air movement. Excess air should be minimized through passive means with the resultant air collected at the proper face velocity to minimize the amount of material removed from the conveyance stream. This design approach utilizes wet dust extraction to protect the environment from fugitive dust release.

All coal dust collection systems serving coal handling shall conform to the latest code for fire protection, and explosion isolation and venting. All ductwork shall conform to adopted codes for transport velocity of combustible dust (Figure 4). Ductwork should have blast gates and bleeder valves arranged appropriately to facilitate balancing the system and to maintain minimum transport velocities. Branch entries should be arranged correctly to prevent dust drop out due to eddy currents.

Washdown systems are another form of active dust control, and when engineered properly, they can deliver acceptable dust control with a lower capital and ongoing cost profile. Washdown systems are typically employed after all passive and active coal dust control measures have been applied. Washdown systems can be as simple as the convenient placement of hose systems up to the design and installation of touchscreen controlled, multizoned, hard-piped systems. Fixed washdown systems should be applied based on risk to the operation and are therefore typically installed in tripper/cascade rooms first (Figure 5). Unfortunately, most plants do not have adequate drainage in these areas to handle new fixed systems and these systems must be designed and installed first.

The Complete Approach

What really enables a utility, or other manufacturer, to make a concrete improvement in the safety of their plants is employing all of these systems together as part of a holistic, sustainable solution. Particle movement at every point throughout the plant should be considered when developing a dust-mitigation strategy to truly address causes, rather than fixing symptoms and potentially creating new deficiencies down the line.

The highest risk plant in Acensium’s recent dust-mitigation project has completely rebuilt its coal-handling system in order to dramatically reduce the explosive dust risk. The utility’s other facilities are implementing upgrades according to schedule. The initial 7-year capital plan has been expanded due to the success of the program to date. Administrative controls recommended by Acensium enabled safety improvements to be delivered in the short-term, while long-term physical improvements continue to be implemented.

Many more utilities are starting similar evaluations to mitigate coal dust risk at their plants. These lead innovators are experiencing safety improvements that are now years ahead of industry contemporaries. ■

—Jason Schwartz is principal at Acensium.