A consortium of European companies, research institutes, and universities have launched the world’s first demonstration of a fully integrated power-to-hydrogen-to-power project, at industrial scale and in a real-world power plant application.

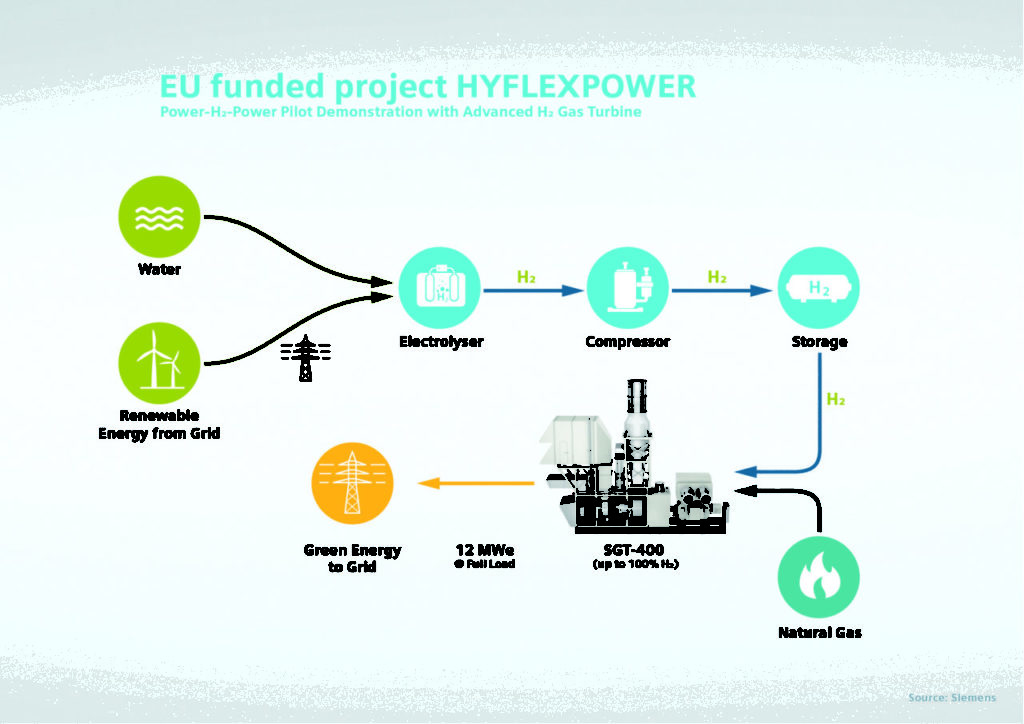

The four-year project to demonstrate HYFLEXPOWER, which has achieved a technology readiness level of 7, will convert a 12-MWe combined heat and power (CHP) plant at Engie Solutions’ Smurfit Kappa pulp-and-paper industrial site in Saillat-sur-Vienne, France, to demonstrate the entire power-to-hydrogen-to-power cycle.

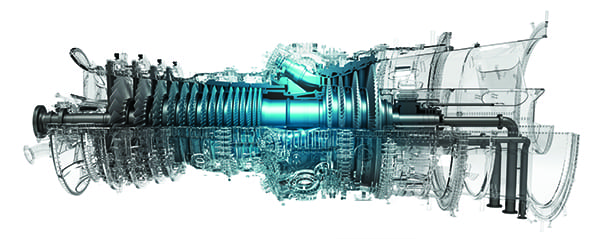

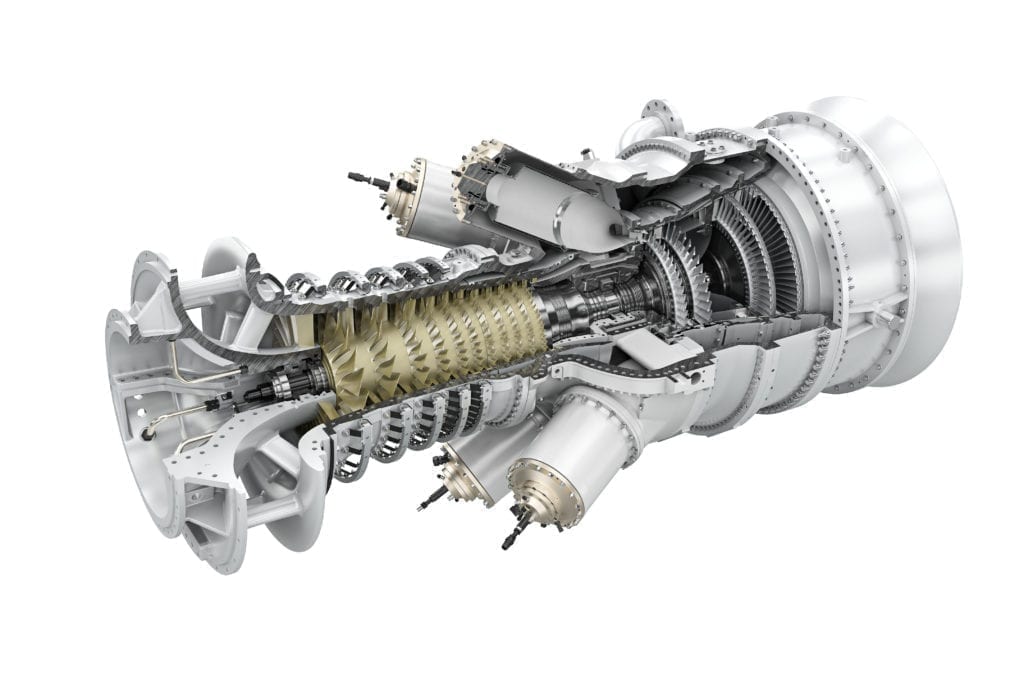

As Engie explained to POWER on June 2, the 2007-installed CHP facility currently uses natural gas from the French grid via a Siemens Gas and Power SGT-400 gas turbine and a recovery boiler to produce power, which is sold to French utility EDF under a regulated feed-in-tariff. It also produces steam, which is used by the Smurfit Kappa papermill to dry pulp from recycling of waste paper to make new paper for cardboard.

A Notable Collaboration

Siemens Gas and Power, which will play the crucial role of project coordinator for the HYFLEXPOWER pilot, will provide an electrolyzer system to produce hydrogen from surplus renewable power in the region. While part of that hydrogen may be used for storage, Siemens will also upgrade the existing SGT-400 industrial gas turbine at the CHP plant to burn a variety of natural gas and hydrogen mixes for power generation, working to gradually step up hydrogen’s volume of the fuel to at least 80%, and eventually, to 100%. Engie, meanwhile, will build the hydrogen production and storage facility, including the natural gas and hydrogen mixing station.

The European Union (EU) will provide €10.5 million ($11.7 million) of the project’s total €15.2 million ($16.9 million) budget through its Horizon 2020 framework program, and the consortium’s diverse partners will provide the rest. While Siemens and Engie will get the bulk of the EU’s funding, other major recipients include UK-based gas turbine generator package firm Centrax, which will upgrade the package for hydrogen operation and install the new turbine.

German Aerospace Center (DLR) will meanwhile coordinate with the University College London, University of Duisburg-Essen in Germany, and Lund University in Sweden to support the hydrogen turbine technology development. As notably, the National Technical University of Athens will perform economic, environmental, and social assessments of the concept, and French project consultancy Arttic will support the operational project management and communication activities.

When the project wraps up as slated on April 30, 2024, it will seek to primarily achieve “operation at full load and production of 12 MW electrical energy with high-hydrogen fuel mixtures of at least 80% by volume hydrogen up to 100%.” Participants also said the tests will demonstrate that “EU emission limits for such installations can be not only met, but also reduced. Finally, the development of an economic assessment for this Power-to-H2-to-Power pilot plant demonstration will be conducted to show the economic benefits of this application.”

To meet the ambitious objectives, the project will be phased. According to Siemens, participants will immediately set out to finalize contracts and kick off engineering development. In 2021, HYFLEXPOWER will then work to install the hydrogen production, storage, and supply facilities at the pilot demonstration site. Work to install the gas turbine for the natural gas and hydrogen mixtures will begin in 2022, and the project will then work to demonstrate an advanced pilot plant concept. By 2023, participants expect to begin pilot demonstration with up to 100% hydrogen.

A Leap for Power-to-X-to-Power

If successful, the demonstration’s biggest takeaway may be that it will show that hydrogen has a role in long-term energy storage on a renewables-heavy grid. “Chemical storage appears to be the most promising long-term energy storage technology,” the participants said. “Among chemical storage technologies, hydrogen is expected to dominate as it can be produced by electrolysis of water using excess energy from [renewable energy sources], easily compressed and stored, and finally re-electrified using gas turbines.”

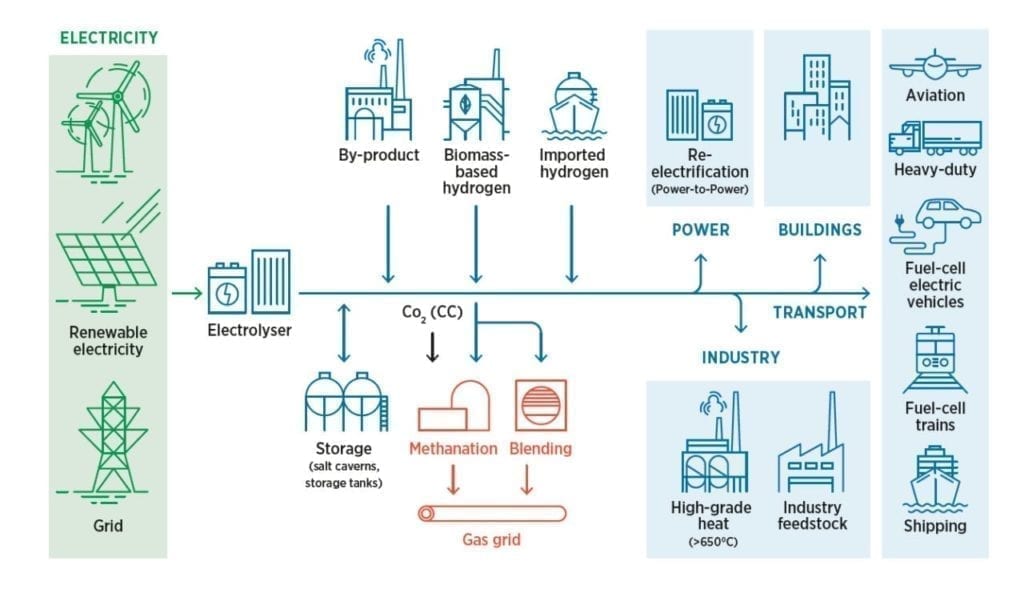

As POWER has reported, while still in its infancy, power-to-gas provides a promising approach to convert renewable power into “green” hydrogen and methane, furnishing the renewables sector with a potentially lucrative array of end-uses. Power-to-gas (sometimes abbreviated P2G or PtG) describes the process of converting renewable energy to gaseous energy carriers such as hydrogen or methane via water electrolysis—mainly alkaline electrolysis, proton exchange membrane (PEM) electrolysis, and solid oxide electrolysis cells. The produced green hydrogen can be used in a range of pathways that promise to decouple renewable generation from electricity demand—helping to avoid surplus curtailment and potentially providing the sector with an assortment of new revenue streams.

(For more, see “Why Power-to-Gas May Flourish in a Renewables-Heavy World” in POWER’s December 2019 issue.)

Over the past two decades, more than 200 projects have started operation to convert electricity and water into hydrogen via electrolysis to reduce emissions—from transport, natural gas use, and industrial sectors—or to support the integration of renewables into the energy system, but most have been pilots or demonstration projects under 1 MW. More recently, owing to increased discussions about P2G’s place in future energy systems and technology advancements, several much larger and more ambitious projects are in planning.

At the same time, developers are rethinking hydrogen’s role in supplying power to the grid. While several hydrogen power projects have been built or planned to supply power to the grid over the last two decades, many involve hydrogen combustion in gas turbines, albeit at low volumes and with so-called “grey hydrogen,” which comes from fossil fuels. More developers are now exploring integrating green hydrogen for power generation. All major gas turbine manufacturers, for example, are currently developing gas turbines that could combust 100% hydrogen, both for peaking and baseload power applications as a decarbonized alternative to natural gas. Other power-to-gas-to-power projects span various applications, including for fuel cells for CHP, industrial heat, and generators.

Since 2000, several projects have been built, are under construction, or are planned that use hydrogen to supply power to the grid with a gas turbine or fuel cell. For more, see in POWER’s October 2019 Big Picture infographic: Hydrogen Power. Source: POWER

The Value of an Integrated Demonstration

However, as the Hydrogen Council—an international CEO-level advisory body—noted in a report this January, while it depends greatly on the region, the eventual costs of renewable hydrogen as they concern power applications matter. Renewable hydrogen from electrolysis today costs about $6/kilogram (kg). But since 2010, the cost of electrolysis has fallen about 60% (from between $10/kg and $15/kg hydrogen to as low as $4/kg), the report says. One example it cites that involves offshore wind–based electrolysis in Germany suggests that by 2030 costs could fall another 60%.

If costs of hydrogen production and distribution continue to fall, by 2030, hydrogen solutions could compete with other low-carbon alternatives in simple cycle hydrogen turbines for peak power, hydrogen boilers, and industry heating, it says. Still, the report concludes that low-carbon baseload supply hydrogen will only be “relevant in regions constrained in renewables potential and situations where alternatives like fossil fuels with direct CCS [carbon capture and storage] or biomass (wood chips or biogas) are not an option.” In such cases, it notes, “companies could import hydrogen and use it to power hydrogen turbines.”

(For more, see POWER’s Feb. 27, 2020, feature, “How Much Will Hydrogen-Based Power Cost?”).

Costs are a major consideration for HYFLEXPOWER’s participants. The project’s full end-to-end integration of an existing renewable power plant, an electrolysis system, and a high-volume hydrogen gas turbine should play an important role in significantly lowering costs and minimizing lead time compared to a greenfield site, they note.

For Engie, the demonstration also offers new opportunities in a lucrative market. Engie already has a number of operational or planned projects to support development of renewable hydrogen for manufacturing applications, including a March 2020–launched project with French electricity distribution organizing authority Morbihan Énergies, and French tire manufacturing giant Michelin. That project, dubbed “HYGO,” formalizes green hydrogen supply to a Michelin site in Vannes, northwest France, for use in its heat treatment processes, as well as envisions a public green hydrogen distribution station for cars and heavy goods vehicles, including for supply to a public vehicle charging station at the Michelin plant. The HYFLEXPOWER demonstration, which will further Engie’s efforts to develop renewable hydrogen for industrial purposes, is “the future,” said Pierre Hardouin, CEO of Engie Solutions for Industries.

Centrax, meanwhile, is looking at it from a technology development perspective. “Our goal is for our gas turbine combined heat and power systems to be ‘Hydrogen Ready’ to provide future proof power generation solutions for our Customers,” said Harry Trump, director of Business Development for Centrax Ltd.

For Siemens, the opportunity offers a holistic effort to prove cross-sector decarbonization using its equipment. As Lisa Davis, CEO of Siemens Gas and Power, noted in a recent white paper, coupling sectors via green hydrogen is set to be a basic element and backbone for an energy future based on renewables.

“Converting electricity into hydrogen or synthetic fuels, thereby making it storable, transportable and useable for all kinds of energy consuming sectors, enhances the application of green energy throughout the entire system,” she said. “The possibilities of its impact on the energy transition call for urgent action in researching, developing and applying the significant potential of Power-to-X, thus unlocking the economic and technologic value it offers to the entire energy system.”

Siemens’ Modular Approach to the Emerging Power-to-X Market

Siemens, notably, appears to be approaching the business opportunity offered by power-to-x through a “modular” approach that involves technology packages covering the full power-to-x application process.

Its renewable power package, for example, offers a renewable energy supply, including grid connection, or a captive power supply. The H2 package offers an electrolyzer, hydrogen compression, and intermediate storage, while the re-electrification package offers long-term hydrogen storage, a hydrogen gas turbine, reciprocating engine, fuel cell, or battery energy storage system. It also offers an “E-Fuel synthesis” package, including a carbon capture solution from flue gases, compression, and synthesis of fuels like methanol and ammonia. Finally, it offers a turnkey package that envisions the company being the engineering, procurement, and construction (EPC) contractor for a power-to-x plant.

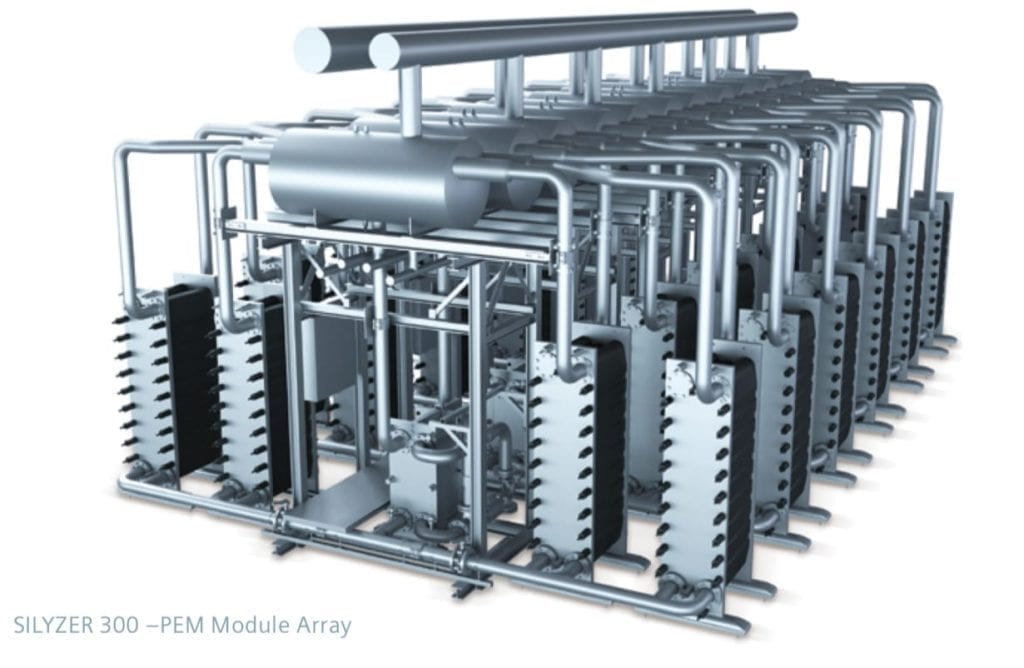

However, work is still underway, to refine specific components that would enable these approaches. Key to Siemens’ “e-Hydrogen” package, for example, are the compressors, which compress hydrogen for storage or refueling to pressures as high as 700 bar. As crucial is the company’s integrated demonstration of an electrolyzer, which will likely come from its Silyzer proton exchange membrane (PEM) portfolio family.

Silyzer systems have already been widely adopted by an assortment of projects worldwide. The 6-MW PEM electrolysis Energiepark Mainz project in Germany, for example, uses a second-generation Silyzer technology (three Silyzer 200 units) to convert surplus power from wind farms into hydrogen. Though it began operation in May 2014, Energiepark Mainz is still one of the largest existing power-to-x projects in the world. While Siemens did not specify what electrolyzer technology it will use at HYDROFLEXPOWER, the company noted that it recently rolled out the Silyzer 300, a system that is targeted to large-scale industrial applications in the “double-digit megawatt range.” That PEM electrolyzer model can produce up to 2,000 kg/hour and has a plant efficiency of more than 75%. However, the company also noted it is working on a PEM model in the range above 100 MW.

In tandem, it is spearheading far bigger power-to-x projects. One notable example is the Murchison Renewable Hydrogen Project in Western Australia, a project Siemens and Hydrogen Renewables Australia (HRA) are jointly developing that could use a Siemens’ Silyzer electrolyzer to convert up to 5 GW of solar and wind generation to produce hydrogen for gas pipeline injection—and later, to export to gas-hungry Asian markets, notably Japan and South Korea. This May, HRA took the significant step of signing a memorandum of understanding (MoU) with Australian Gas Infrastructure Group (AGIG), a company that already has green hydrogen projects in four Australian states. The MoU seeks to fast-track hydrogen development in Australia, and it will also examine the feasibility of injecting hydrogen into the pipeline from the Murchison project, which is located just north of Kalbarri in midwest Western Australia.

The Quest for a Decarbonized Gas Turbine

Specifically interesting to the power sector may be Siemens’ exploration of systems to enable efficient “re-electrification.” The package it offers essentially involves high-capacity storage of electrical energy produced and compressed via the e-Hydrogen package, as well as combustion in gas turbines (both simple and combined cycle), engines, or fuel cells.

It says the best use case for re-electrified power over the short term may be for grid balancing, because electrolysis could act as a “fast negative energy balancing unit” in the event the grid is overloaded from renewable energy sources (RES). Large over-capacities of RES already exist today, it notes. “Storing the surplus electrical energy of those sources in chemical form may become more lucrative than curtailing the capacity of renewables in peak production times.”

Siemens is not alone in exploring a market for re-electrification options. While HYFLEXPOWER will be the first high-profile integrated demonstration, several of its major gas turbine competitors, including GE Power, Mitsubishi Hitachi Power Systems (MHPS), and Ansaldo Energia, have made gains in carving out niche applications for their high-volume hydrogen turbines. MHPS this March, notably, bagged its first order for an advanced gas turbine designed to transition to renewable hydrogen fuel from Utah’s state-owned Intermountain Power Agency. MHPS told POWER it plans to transition the J-series turbines to burn 100% hydrogen by 2045.

And while Ansaldo in October 2019 partnered with carbon capture specialist Equinor to validate a 100% hydrogen gas turbine combustor, the Italian company is part of several prominent European and international projects. These include EncapCo, a project to develop premix combustors for hydrogen-rich combustion; DECARBIT, which is developing reheat combustors for 100% hydrogen; and BigH2, which is studying fuel injector fundamentals.

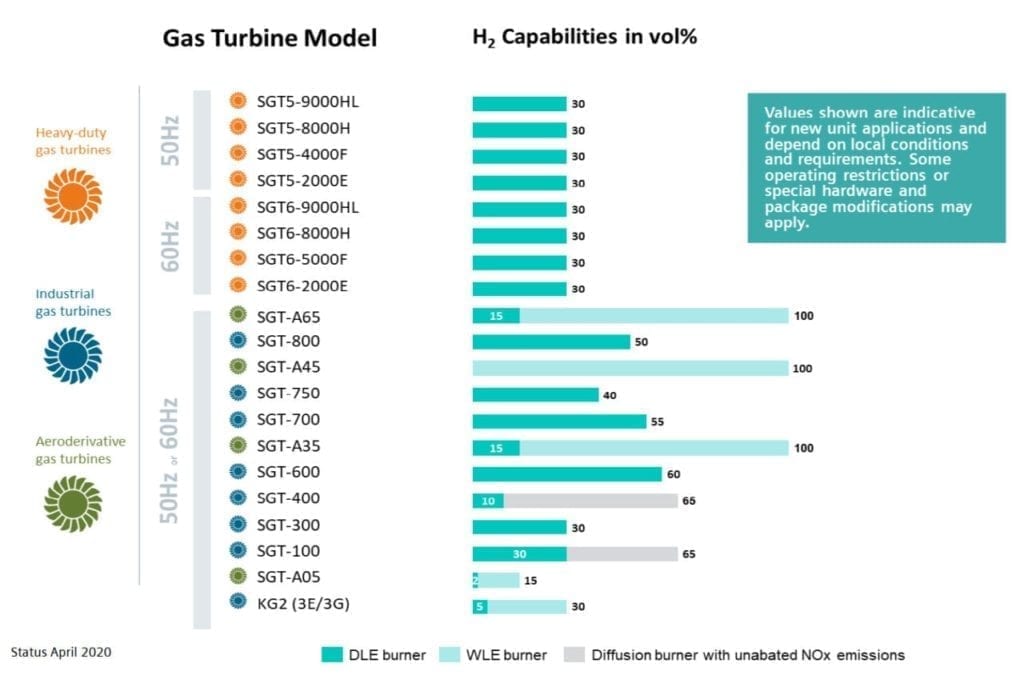

Like Ansaldo, Siemens is part of the EUTurbines industry association, a body that in January 2019 committed to developing gas turbines capable of operating on 100% hydrogen by 2030. And as with GE Power, whose turbines have been producing power from varying mixes of hydrogen for decades, Siemens said most of its turbines are already hydrogen capable “to a far extent.”

Leveraging experience it has gained since the 1960s with more than 55 hydrogen-burning turbines around the world, Siemens has so far made notable progress on its ambitious roadmap to increase the hydrogen capability in all its turbine models to at least 20% by 2020, and 100% by 2030. Last year, for example, it announced that all its aeroderivative units outfitted with wet low emissions systems (based on diffusion burner technology) already fulfill the 2030 target of 100% hydrogen capability.

The HYFLEXPOWER project will seek to demonstrate 100% hydrogen capability of its industrial turbines outfitted with dry low emissions (DLE) technology, Siemens told POWER. The existing Siemens SGT-400 turbine involved at the HYFLEXPOWER project is a small industrial gas turbine that uses G30 burner technology, a proven radial swirler premixing design that allows for fuel flexibility, and has demonstrated the capability to operate on up to 10% volume of hydrogen, it explained. Siemens now plans to get it to 100% hydrogen by upgrading its DLE combustion technology through a research and development program on its burner technology.

“Siemens Gas and Power wants to be the driving force behind the decarbonization of energy systems worldwide,” said Karim Amin, CEO of Siemens Gas and Power’s Generation division. “Our goal is to make our gas turbines usable for 100% hydrogen. With that, our gas turbines can be the ‘technology of choice’ for our customers to complement the intermittence of renewables and ensure a secure energy supply in the decarbonized world of the future,” Amin said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).