The electric power industry is a large water user and is dependent upon reliable water supplies. Adopting new water-conserving technologies for power production can help alleviate the impact of future water shortages. Several water use reduction technologies are available, each with different benefits and costs.

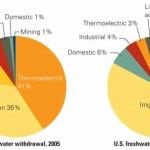

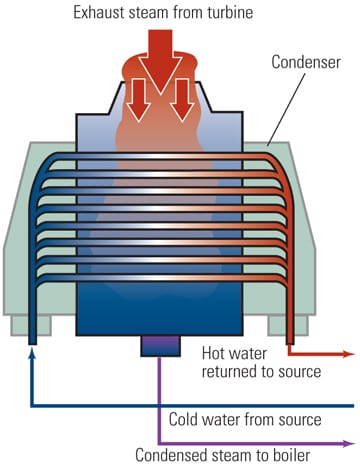

By far the largest use of water in power generation is for condenser cooling. Thermal power plants require a large amount of cooling water to condense the steam turbine exhaust steam. The lower the condensing temperature, the lower the backpressure on the steam turbine, which increases plant thermal efficiency. The most effective method of rejecting this heat is through the use of cooling water. Traditionally, power plants have used three methods for condenser cooling: once-through, evaporative, and dry cooling. Each has unique advantages and disadvantages.

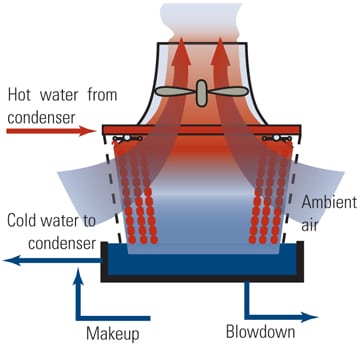

With once-through cooling, water is withdrawn (typically from a lake, river, or ocean), pumped through a condenser, and returned to the source at the same rate but at an increased temperature (Figure 1). Once-through cooling provides the best power plant efficiency of all the alternatives (such as cooling towers) because the source water tends to be the lowest temperature heat sink available for most of the year.

|

| 1. Once-through cooling. Steam exhausted from the steam turbine typically enters the condenser from above and is condensed by the relatively cold cooling water flowing through the condenser tubes. Source: EPRI |

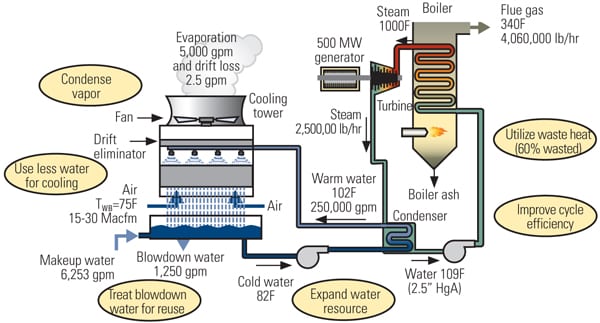

Evaporative cooling is often used when larger water volumes are unavailable, as in the arid, western U.S. The recirculating water is cooled either in a cooling tower or cooling pond and then recycled back to the condenser (Figure 2). Evaporative cooling typically provides the second-best plant efficiency, because the condensing temperature approaches the ambient wet-bulb temperature. Plants with cooling towers typically withdraw less than 5% of the cooling water of a comparable plant with once-through cooling, but the actual water consumption (evaporative water loss) is higher.

|

| 2. Wet cooling tower and recirculating cooling. A cooling tower cools the warm water from the condenser through evaporation, rather than heating large volumes of ocean or river water for once-through cooling. The disadvantage is that freshwater makeup is required to replace evaporation, drift, and blowdown from the cooling tower. Source: EPRI |

Figure 3 shows a schematic of water use in a typical 500-MW thermal plant with a wet cooling tower. The cooling tower in this example requires 6,253 gpm of freshwater when running at full load. Makeup is required to replace the water lost to evaporation, drift, and cooling tower blowdown.

|

| 3. Balanced water use. This schematic shows the water makeup requirement for a typical 500-MW thermal plant using evaporative cooling towers. Source: EPRI |

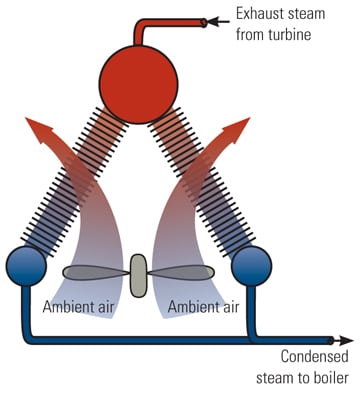

With dry cooling, heat is rejected from the condenser to the atmosphere by passing air over the outside of a heat exchanger. There are generally two types of dry cooling: direct and indirect. In direct dry cooling, steam is ducted to the air-cooled condenser (ACC), where it is condensed (Figure 4). This cooling process has been used at dozens of gas-fired combined cycle plants, largely located in the western U.S. With indirect dry cooling, the steam is condensed in a traditional condenser by cooling water that is then pumped to an air-cooled heat exchanger. Hybrid systems combine wet and dry cooling processes. To date, there has been limited application of indirect dry cooling in the U.S., and it has not been retrofitted to existing power plants.

|

| 4. Air-cooled condenser. Exhaust steam from the turbine is condensed on the inside of the ACC by air flowing past the outside of the tubes. The condensed water is then returned to the condenser. Unlike once-through cooling and wet cooling tower options, the air-cooled condenser requires no cooling water, although the system requires additional auxiliary power to run the cooling fans and suffers higher efficiency penalties at elevated ambient temperatures. Source: EPRI |

Current Water Use in Power Plants

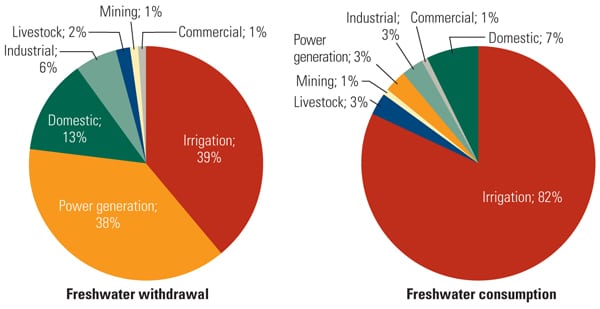

According to the U.S. Geological Survey (USGS), thermoelectric power plant cooling accounts for approximately 40% of U.S. freshwater withdrawals (Figure 5). Agricultural irrigation accounts for approximately the same amount. Most of the water withdrawn by thermoelectric generation is discharged to the water body (once through cooling), so only approximately 3% of total U.S. freshwater consumption is used for electricity generation (Figure 5).

|

| 5. Freshwater withdrawal and consumption. A large portion of the water used by power plants is for once-through cooling, where cooling water is returned to the source water body at a slightly elevated temperature. Agricultural irrigation is by far the largest consumer of freshwater in the U.S. Power plants consume a much smaller fraction of freshwater. Sources: EPRI, USGS |

After 1995, the USGS stopped reporting water consumption values; water use numbers were reported for 2000 but have not changed substantially since 1995 and have possibly decreased with reduced operation of the nation’s coal-fired plants in recent years. However, percentages of withdrawal and consumption vary widely throughout the U.S.

The increasing application of recirculating cooling systems (for example, wet cooling towers), in addition to freshwater conserving measures, reduced the electric power industry’s water withdrawals per unit of electric power generated by a factor of three, from 63,000 gal/MWh in 1950 to 21,000 gal/MWh in 2000. Over the same period, power output increased by a factor of 15. The net result is a five-fold increase in water withdrawals by the electric power industry over this 50-year period. All of this increase occurred before 1980, and water use rates for power generation have steadily declined since then. With the recent increase in combined cycle plant operation, reductions in water withdrawals should continue in the future.

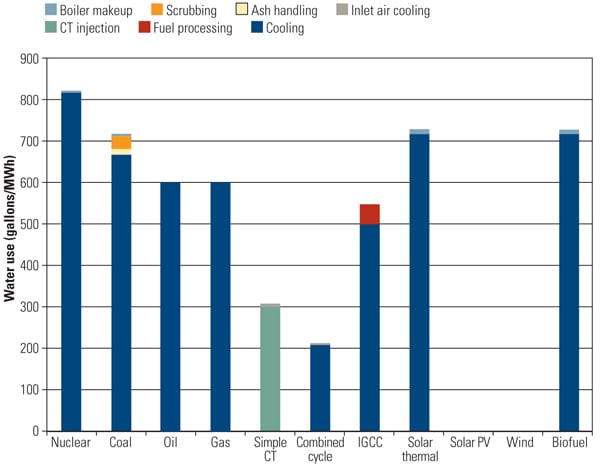

Power plant water use varies with the type of generation. Figure 6 depicts average water use values for closed cycle cooling (wet cooling towers) for each type of plant, based on actual U.S. plant data.

|

| 6. Water use by power plant type. Water use varies widely among the different power plant types. For example, simple Rankine cycles are the most water-intensive, while solar photovoltaic and wind energy use no water to generate electricity. The analysis assumes closed-cycle wet cooling towers are used. Gas-fired combined cycle plants use about two-thirds less cooling water than a coal-fired plant, yet the typical solar thermal plant uses about the same amount of water as a coal plant of equivalent capacity. Source: EPRI |

Conservation Options for New Generating Units

In general, it is much easier to accommodate water conservation in new plant designs, because the entire plant can be designed around the equipment and its performance can be optimized. Retrofit projects are more problematic.

There are four major strategies for reducing freshwater use in thermoelectric generation. Each has been used to varying degrees at different power plants, depending on local water resources and capital and operating costs:

- Use alternative (or degraded) water sources.

- Use dry or hybrid cooling technologies.

- Increase the plant’s thermal conversion efficiency.

- Recycle water within the plant.

Alternative or Degraded Water Sources. Many power plants operate with nontraditional or degraded water sources, particularly treated sewage effluent. Treated sewage effluent has been the most attractive source because of its year-round availability, inexpensive price (although prices are increasing), relatively low cost of treatment, and minimal impacts to operation. Even this water source is being protected in some areas of the country for use in irrigation and groundwater recharge, limiting its use for power plant cooling.

Additional degraded water sources under consideration include:

- Seawater and brackish water from coastal areas (for cooling towers)

- High-salinity groundwater

- Mine water and produced water from oil and gas wells

- Agricultural runoff

- Storm water

Each of these sources will cost more than traditional surface or groundwater sources, with the highest costs usually a result of treating the water and transporting it to the power plant. Additional costs can come from the need to use different materials to minimize or avoid corrosion; chemicals to prevent scaling, fouling and corrosion; a storage or backup water system; and wastewater treatment and disposal.

Dry or Hybrid Cooling. Although dry cooling can virtually eliminate power plant cooling water needs, it presents several challenges to cost and plant performance.

The total capital cost for power plants with dry cooling is typically more than 10% higher than power plants equipped with wet cooling, due to requirements for large finned-tube heat exchangers, fans and drive motors, and steel structures to provide ground clearance for proper air circulation. The capital cost of the dry cooling system itself is three to five times higher than for a wet cooling tower, and dry cooling operating costs are higher. Overall, EPRI estimates that the cost of dry cooling the typical 500-MW steam plant introduced in Figure 3 adds about 12.6% to the average capital cost of the typical once-through or wet cooling tower approach.

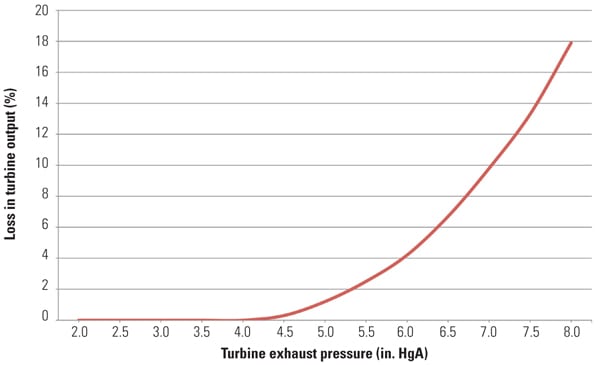

The fans needed for air circulation are much more powerful and numerous, increasing the unit’s parasitic load and reducing the net power. Dry cooling provides a steam condensing temperature typically 40F+ higher than the dry-bulb temperature, reducing average unit efficiency by 10% or more on the hottest days. The unit may also experience a reduction in capacity on hot days (Figure 7).

|

| 7. Hot day power loss. The performance of a typical 500-MW coal-fired plant using dry cooling is highly temperature-dependent; therefore, expected plant performance will vary considerably, based on location. Source: EPRI |

As a consequence of the efficiency penalty for dry cooling, the plant requires more fuel to produce the same amount of electrical energy compared with once-through cooling or cooling towers; therefore, the emissions of air pollutants and CO2 per unit of electrical energy delivered (pounds of pollutant per MWh) are greater.

There are other practical consequences for operators of dry cooling systems. Dry cooling systems are significantly larger than traditional wet cooling towers and require additional land. The large number of cooling fans can create noise issues, which can be alleviated with the purchase of low-speed, low-noise fans—but those add to costs.

Also, high winds can stall airflow in leading edge fans, causing a sudden drop in ACC performance and translating into higher backpressure on the steam turbine. The control system will generally reduce steam flow to the turbine as the backpressure alarm point is approached, which reduces unit generation capacity. Under gusty wind conditions, there have been cases where the controls and system components did not respond fast enough to limit backpressure, and the units tripped off line to protect the turbines from damage.

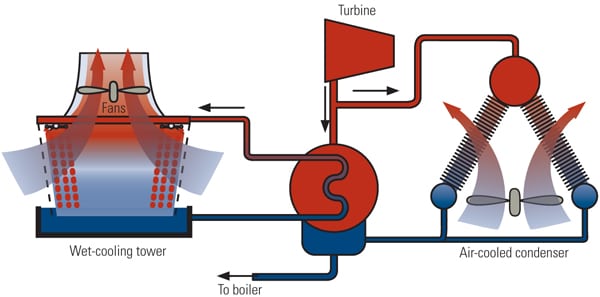

Hybrid systems combine wet and dry cooling towers (Figure 8). This arrangement allows most of the heat to be rejected to the atmosphere on cooler days, avoiding the use of cooling water, while maintaining the power plant’s thermal efficiency during hot days, with the wet tower taking part of the cooling load.

|

| 8. Hybrid cooling system. A hybrid cooling system combines the best features of the wet cooling tower and the air-cooled condenser. Source: EPRI |

Hybrid cooling is becoming more popular because the tower sizes can be minimized to reduce additional costs, and performance is better than with air-cooling only. There are many ways to optimize such a system, depending on the goals of the plant design and the available water sources. EPRI guidelines are available to assist plant designers with this optimization process.

Increased Thermal Conversion Efficiency. High-efficiency natural gas combined cycle power plants have a large benefit from a water conservation standpoint, as shown in Figure 6. Because the combustion turbines produce roughly two-thirds of the power, cooling water consumption is reduced by an equivalent amount. In addition, the steam from the turbine can be condensed by ACCs, further reducing water use. The ACC will be smaller, as it is only cooling the steam turbine, about one-third of the combined cycle plant’s power output, which minimizes hot day efficiency penalties. Combustion turbines will also sustain a hot day capacity penalty. This penalty, however, can be mitigated with inlet sprays or evaporators, or with inlet chillers that draw power.

Water Recycling. Power plants in operation today already employ many practices to reuse water. Water is typically “cascaded” from one use to another, depending on the quality of water that is needed for each process.

Another potential place for recycling is stack gas. A significant amount of water is lost through power plant stacks (flue gas from fossil fuels contains 8% to 13% moisture as a byproduct of the combustion process) and cooling tower plumes. Several research groups, including EPRI, are funding work to develop technologies to economically recapture water from plumes, but these technologies are not yet commercially available.

In the meantime, to the extent that renewable technologies can economically penetrate the generation mix, water use can be reduced. Renewable energy from wind, solar photovoltaic, geothermal (when using brine for cooling water), hydroelectric, marine, and hydrokinetic sources all require little to no water consumption. Solar thermal is the one notable exception.

Water Conservation Options for Existing Power Plants

Options for existing plants are more limited than for new ones, as the available conservation methods usually require major modifications to the boiler and steam turbine and may have other environmental and permitting constraints. The associated cost increases may limit the economic viability of the plant. Some of the options that have been suggested or considered for water conservation at existing power plants are examined below.

Retrofit Closed-Cycle Cooling (Wet Cooling Towers). Although water withdrawals would be reduced by over 95% with wet cooling towers, the evaporative losses would approximately double. EPRI has a significant body of research estimating costs and other impacts of retrofitting cooling towers to all U.S. plants using once-through cooling.

The retrofit of wet cooling towers will result in negative consequences, such as lower thermal efficiency and correspondingly increased air pollutant and CO2 emissions per unit of electrical energy (MWh) generated, cooling tower drift, and blowdown issues. In addition to the cost of purchasing and constructing cooling towers for the plant, the designer would need to consider whether to reoptimize the remainder of the power plant to reduce the efficiency penalty.

Retrofitting to cooling towers may also require water pretreatment (softening/clarification), scale and corrosion inhibition additions, and blowdown treatment for discharge regulations, including possible zero liquid discharge. All of these treatment processes (plus the cost of the cooling towers) will add millions of dollars of infrastructure as well as significant operational and maintenance expenses.

Retrofit Dry Cooling. Dry cooling retrofits are very difficult for existing plants, and the high retrofit costs may render the plant uneconomic to operate. The balance of the plant would have to be redesigned to work with the dry cooling system, because it operates at such different conditions than wet cooling towers for five distinct reasons:

- Dry cooling will cool to the dry bulb temperature, whereas a wet cooling tower cools the water to the wet bulb temperature. Turbines designed for new plants to be equipped with dry cooling are normally modified to accommodate the expected higher turbine backpressure.

- Air-cooled systems work most effectively when the steam is ducted straight to the ACC. There are two options for converting a water-cooled plant to air cooling: use indirect dry cooling, where the steam is condensed by recirculating water and the heated water is routed to an air-cooled heat exchanger, or remove the condenser and route the steam directly to an ACC. Because the ACC has a lower efficiency impact (by eliminating the temperature drop across the condenser), it would be the preferred choice over indirect dry cooling. Removing the condenser and circulating water lines and routing large-bore steam piping past the turbine pedestal and to the ACC would be difficult and expensive, especially below grade level.

- Air-cooled systems are typically used on combined cycle plants for the reasons presented earlier. This is one reason why, in recent years, the predominant plant built in the western U.S. (where dry cooling is needed) has been natural gas combined cycle plants.

- In addition to the efficiency penalties discussed above, hot day operation with ACCs can result in capacity loss, which usually coincides with peak system load (air conditioning) and the highest power prices. This occurs because as turbine backpressure rises to near trip points, the operators must reduce steam flow to prevent a unit trip (Figure 9).

- Retrofitting ACCs to an existing unit would affect plant operation and internal assets. For example, iron corrosion and transport is typically an issue with units on ACCs. It would be even worse with the mixed metallurgy found in conventional boilers and steam cycles.

|

| 9. Lost hot day performance. The main disadvantage of the air-cooling tower is that on hot days, turbine back pressure rises more quickly than in the typical once-through or wet condenser cooling system. Rising condenser pressure means lost steam turbine performance and efficiency. Source: EPRI |

Convert to Partial- or Full-Degraded Water Use. This method is probably the easiest water conservation technique to adopt for existing plants. Its advantages are that the thermodynamics of the plant and the power block equipment remain largely unchanged. Depending on the distance of the source water from the power plant, transportation costs (building pipelines and pump stations) can be one of the largest expenses, but there may also be costs associated with water and wastewater treatment systems and chemical additives. The plant would also need to be evaluated to ensure that construction materials are compatible with the expected water quality.

Water Shortage Sharing Agreements. EPRI is currently implementing a variety of tools to assist electric power companies with water issues. For example, WaterPRISM is a modeling tool that allows stakeholders in a given watershed to evaluate water reduction and sharing options. This can even include special reductions during drought periods—such as providing revenue streams to support shifting agricultural land to non-irrigated crops or non-use for the drought periods.

Looking Forward

Water availability could become a major issue for the electric power industry over the next decade and beyond. Siting of new plants is already constrained by access to cooling water, especially freshwater. Electric power is frequently assigned the lowest priority for water allocation after residential, commercial, industrial, and agricultural uses. With limited freshwater supplies and increasing demands, it is critical to examine options for reducing anticipated demand within the electric sector given its critical role in powering the U.S. economy. This demand must be viewed in light of weather/climate variability and new technologies expected to enter the marketplace.

The electric power industry is changing rapidly in response to new environmental policy and regulatory requirements, natural gas prices, and the replacement of aging infrastructure—among other issues. Although water conservation practices can be implemented for existing plants, the larger conservation opportunities using advanced cooling technologies are more easily and cost-effectively achieved in the design and construction of new generating plants.

EPRI and its members are working with stakeholders and researchers to improve existing technologies by, for example, reducing the cost and energy penalties associated with air-cooled condensers and treating wastewater for reuse. EPRI is also examining and testing a suite of new water conservation technologies. These include thermosyphon coolers, dew point cooling, and nanoparticles, all of which show promise to further reduce water use in electricity generation while preserving overall plant efficiency.

— Kent D. Zammit (kezammit@epri.com) is senior program manager for Water & Ecosystems programs for the Electric Power Research Institute.