Gravity Power LLC—a startup based in Santa Barbara, California—has developed a low-cost, quick-start, and fast dynamic response energy storage technology that competes with classical pumped storage hydro and gas turbines for peaking and intermediate duty power generation. The system is simple, yet its potential is profound.

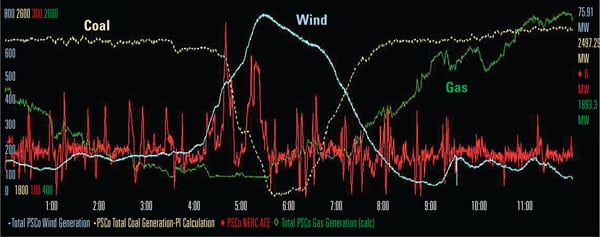

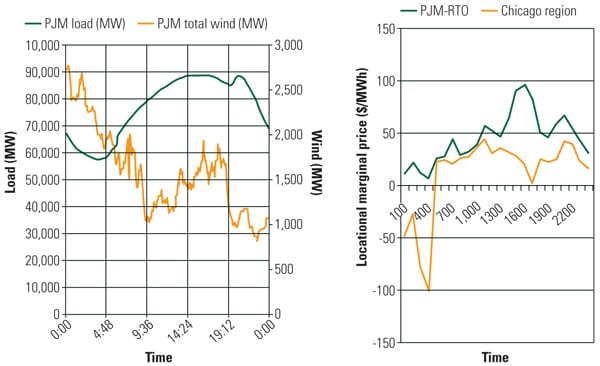

Much of the power generation equipment now being installed is either for renewable energy (predominately wind and solar) or gas-fired combined cycles that leverage the historic low prices of natural gas. However, many of those gas-fired plants were built with an additional purpose: to serve as a fast-reacting source of electricity that can replace renewable generation when the wind stops blowing or the sun doesn’t shine. A better technology choice for “chasing” wind and solar is bulk electricity storage.

The system planning and grid operation complications posed by renewables were thoroughly discussed in an earlier article (“Energy Storage Enables Just-in-Time Generation,” April 2011, available at powermag.com). The key theme of that article was that utility-scale energy storage must be commercialized before renewable electricity can reach its full potential.

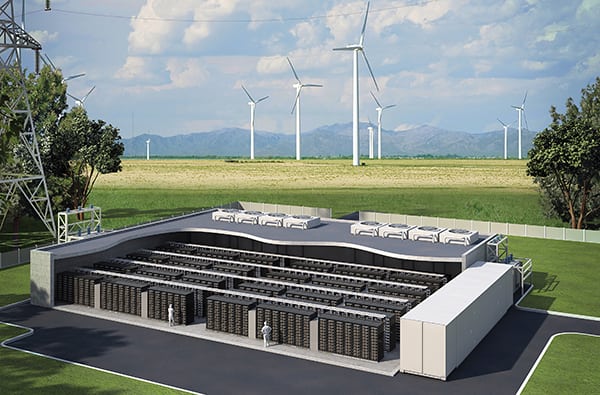

Today, most large energy storage projects appear to be little more than a shipping container filled with tens of thousands of small batteries. The value of energy storage is truly realized with utility-scale systems capable of “moving” bulk wind power produced chiefly during off-peak hours to on-peak hours when the value of the energy is significantly greater. The value is equally important to solar photovoltaic systems that wildly cycle when clouds pass overhead.

Several large-scale energy storage technologies in their early stage of development were discussed in the earlier article. Gravity Power LLC was identified as a company that stood out from the others, principally because its technology fully embraces the KISS principal (Google it) and should be deployable in the near term. In fact, the U.S. Department of Energy took a look at the technology and was unable to fund development work because no research and development was needed.

In the time it takes to read this article, even nontechnologists will intuitively understand how the system works and appreciate its simplicity.

According to Gravity Power CEO Tom Mason, the final design concept took shape in 2008, which was immediately followed by the company’s first round of funding in early 2009 from The Quercus Trust, followed by a series of other small investments. The company is currently raising a Series B round to fund final design and testing of the system. The first Gravity Power patent covering its technology was issued by the U.S. Patent Office in May 2012, and other global patents are pending.

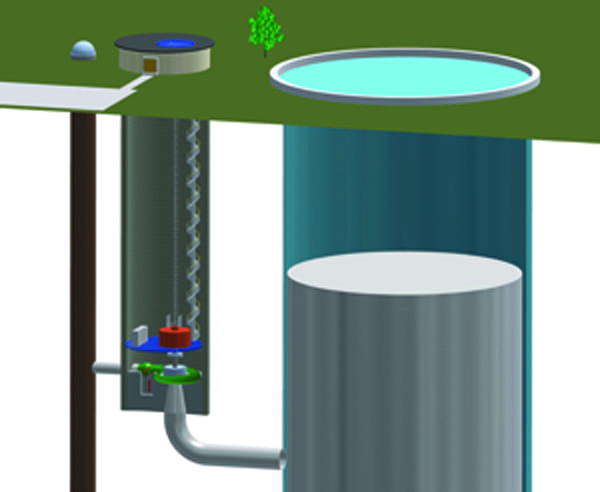

Simple Technology

The Gravity Power Module (GPM) is a simple machine (Figure 1). At the heart of the system is a reversible pump-turbine and motor-generator, much like those used in conventional pumped storage hydro (PSH) systems for 70 or more years. Sitting 40 meters (m) below ground is the top of an underground “water circuit” where the pump-turbine is located. The circuit consists of two sealed water-filled vertical shafts. The first is a large-diameter vertically bored shaft called the “power shaft.” The smaller is the “penstock” shaft. Within the power shaft rests a large piston that stores or returns energy when hydraulically moved up or down by water. The water is simply a hydraulic fluid. The water flows in a circuit in both directions: Either water flows within the system loop, pushing the piston up, or the water is being pushed in the other direction by the piston as it drops.

|

| 1. Gravity works. The piston (shown in red) moves up and down in the power shaft, depending on its operating mode. Power from the grid is used to pump water (the pump is shown in green) into the power shaft and raise the piston. When electricity is required, the piston drops, forcing water through the pump that now functions as a turbine, producing electricity from the motor that now functions as a generator. The penstock shaft is used to capture and return water to the system. Courtesy: Gravity Power LLC |

Much like a conventional PSH system, electricity is consumed when the reversible drive pumps the water from the penstock into the power shaft below the piston, lifting the piston to store the piston’s potential energy. To release its stored energy, the piston is released, and as it descends, water is forced through the pump that is now acting like a water turbine and generating power using the motor that now functions as a generator. The speed at which the piston drops determines the instantaneous power generated. The depth and diameter of the power shaft and the mass of the piston determine the amount of energy stored.

Once explained, the function of the system is intuitive. Gravity does most of the work.

The response of the system is on par with modern PSH systems and much faster than other fossil-fueled backup power sources. A synchronized pump-turbine motor-generator can ramp from zero to full power in less than 15 seconds. The overall energy storage efficiency (power produced divided by the power consumed to charge the system) exceeds 80%. Also, siting of the facility is very flexible: 1,600 MW or more can be installed on less than three acres, unlike a typical PSH system that requires two large reservoirs and perhaps 15 to 20 years to complete the environmental permitting process and construction.

Gravity Power proposes that its first commercial demonstration GPM be designed with a 30-m-diameter power shaft extending 500 m deep. These design parameters will produce the equivalent of 160 MWh, or 40 MW for 4 hours of bulk energy storage in return for consuming 40 MW for about 5 hours. The cost of this system is estimated as $4,400/kW or $1,100/kWh.

Although constructing the first demonstration project is the major hurdle now facing Gravity Power, Mason is looking beyond the demonstration project to a future commercial product line. His goal is to construct larger systems, ranging upward from 200 MW to 1,600 MW and greater with estimated sell prices of $2,000/kW to $950/kW, based on scale economies, perhaps dropping as low as $500/kW in special cases where existing infrastructure is available. These are “overnight” cost estimates (they don’t include the cost of money during construction) and carry the usual exclusion caveats: land purchase, permitting, transmission interconnect, water fill, and other developer soft costs. The estimates do include a generous 25% contingency.

As good as the system sounds, a solid product, market interest, and government support doesn’t guarantee success. Investors demand a strong commitment from customers, while utilities (thought to be the primary customers for the GPM) want to see for themselves a demonstration plant in operation. Building serial No. 1 is the sticking point for Gravity Power, which is ready to move forward today, as it will soon become for other bulk energy storage technologies now on the drawing board.

Within the U.S., the challenge is compounded by a flat rate of load growth that dampens utility enthusiasm to offer power purchase and sale agreements that will incentivize developers and excite investors. Many utilities look upon bulk energy storage as another loss of load instead of a progressive step toward a hardened yet very responsive smart grid.

Successful commercialization of developing energy storage technologies will also require electricity markets to formally place a tangible value on bulk energy storage. Several regions are now developing specific tariffs for energy storage, in conformance with Federal Energy Regulatory Commission Orders 890 and 719, which require independent system operators to develop tariffs and market rules for nongenerating resources. Current market rules focus on real-time or day-ahead markets, where bulk energy storage technologies must be assured of a long-term revenue stream, such as power purchase agreements or feed-in tariffs for their products, in order for developers of new technology to attract investors. The California Public Utilities Commission, for example, recently put forward a proposal that will surely accelerate the commercialization of bulk energy storage technologies in its state (see sidebar).

Engineering and Construction Plans

The GPM concept of operation may be straightforward, but investors and potential purchasers must ensure their investment dollars are not exposed to excessive risk, particularly product cost, construction, and schedule risks. Gravity Power commissioned Babendererde Engineers, underground engineering and construction experts located in Bad Schwartau, Germany, to produce GPM construction plans, cost estimates, and schedules. That work was further examined by Hochtief, a large international engineering and construction firm headquartered in Essen, Germany.

After completing its analysis of the GPM, Hochtief has offered to construct GPM plants, providing customary warranties. Andritz Hydro, the world’s largest manufacturer of pump-turbines, has also signed on to supply equipment with customary warranties, as have other equipment suppliers. Mason said the GPM preliminary design, which includes engineering and construction details for all the critical elements of the system, is nearing completion.

The most significant task in building a GPM is constructing the power and penstock shafts. Shaft construction uses open pit mining techniques, and the pump-turbine motor-generator is the same design as that used for classical pumped storage. The piston is constructed of rock, either carved in place or removed and mixed with concrete. The piston is then encased in reinforced concrete, covered with a stainless steel skin, and mounted on a steel base plate.

The civil work, which includes construction of the power shaft, penstock shaft, and the piston, will take approximately two years and four months for the 160-MWh-size system (40 MW for 4 hours). The project’s critical path is the delivery schedule for the rotating equipment.

Interest Grows in Germany

The German grid is undergoing dramatic changes caused by the shutdown of its nuclear plants and its fast-rising reliance on wind and solar power. The Neckar-Alb Region in the German state of Baden-Württemberg is considering GPM technology in lieu of one or more of the five proposed conventional PSH plant designs (each over 300 MW) that would provide backup to its renewable energy assets.

As expected, these large PSH plants are running into severe public opposition and zoning issues, making it impossible for Baden-Württemberg to proceed with its Regional Plan. Regionalverband, the local planning authority, has included the GPM as a cost-effective alternative to classical PSH in its revised resource plan, which was approved and published in April 2013. The Regional Plan provides the legal framework that qualifies technology selections in this region of Germany. This is the first time that a new storage technology has been included in its regional grid planning. The Neckar-Alb Regionalverband also is investigating two sites for a 300-MW GPM, and GPM is being seriously considered as a less-invasive replacement for a proposed 700-MW conventional PSH project in Bavaria. Clearly, the market for bulk energy storage is booming in Germany.

Although there is considerable interest in large-scale bulk energy storage in Germany, barriers remain. For example, the existing German feed-in tariffs do not include energy storage. These issues may be resolved after the fall elections, when the newly elected German Bundestag considers legislation for federal and state support of bulk energy storage technologies.

Next Steps

To maintain its market momentum, Gravity Power must complete the Series B round financing while completing final steps of product development. The final design hurdle is developing the piston seal. The GPM uses a stationary seal system mounted halfway down the main shaft. The seal must have low friction along the moving piston but must also hold against a pressure differential of ~500 psi and accommodate small piston diameter variation. In planning is a 2-m seal test to identify the optimum sealing material, followed by a full-scale 30-m test at full pressure and maximum piston speed. The seal development is a solvable problem; it may even involve using an off-the-shelf product.

The piston seal is the last preliminary design milestone for the GPM. The next step is to build the proposed demonstration plant. It is for these tests that the Series B round financing is being sought.

Gravity Power holds the promise of reasonably priced, easily sited, and insignificant-environmental-impact bulk energy storage. I predict that the GPM will soon be a critical part of grid of the future, both in the U.S. and other countries.

— Dr. Robert Peltier, PE is POWER’s editor-in-chief.