Npower plans big coal plant in UK

Npower, the British generation subsidiary of German energy giant RWE, is planning to build a 1,600-MW supercritical coal-fired plant to replace an existing 1,000-MW coal power plant in Tilbury, Essex.

The new plant would cost nearly $2 billion and be the first new coal-fired plant built in the country in more than 20 years. In documents filed with the Department of Trade and Industry, npower said it will replace the existing pulverized coal plant (Figure 1) with two 800-MW supercritical units. The new station would be capable of burning biomass as well.

|

1. Days are numbered. Npower plans to replace this 1,000-MW coal-fired plant in Tilbury, UK, with a new, two-unit, 1,600-MW supercritical coal station. Courtesy: RWE npower

|

Npower considered retrofitting the Tilbury plant with carbon capture technology but concluded that it makes more sense to build new units that emit considerably less carbon dioxide (CO2) per unit of output. Npower expects the new plant to be in service by 2013. In the meantime, the existing plant will continue operating.

Andy Duff, npower’s CEO, said, "Coal is a vital component of the UK’s future generation mix, but the environmental impact must be addressed. A supercritical coal plan on its own would result in a significant net reduction in CO2 levels, but we have also chosen to make the [new] power station ready for carbon capture and storage technology."

Duff added that the company remains interested in carbon capture and sequestration. "At this time," he said, "there are still many financial, legal, regulatory, and technical hurdles to clear on CO2 transportation and storage technology. However, [CO2 emissions are] too important to ignore, and we are committed to further research and development as we assess our next steps in this area."

Npower said it chose the Tilbury site "because of its proximity to areas of high population and demand." The company says it will be reaching out to the local community and stakeholders as it develops the details of its plan.

A month before the Tilbury announcement, npower announced a $1.8 billion investment in a new natural gas–fired project, to be based in Wales or Nottinghamshire, and in three new wind farms.

Berkeley boffins make thermoelectric discovery

Researchers at the University of California, Berkeley, have generated electricity from heat by trapping organic molecules between metal nanoparticles, potentially paving the way for a new source of energy.

The discovery was described in a recent issue of Science Express, the online version of Science magazine. It could be a milestone on the path toward ways to directly convert heat into electricity. Current generation techniques are dominated by generating steam in a boiler and using it to spin a turbine and drive a generator.

Conventional ways of generating power waste a lot of heat, as anyone who has ever had a car with a bad radiator knows. According to Arun Majumdar, a Berkeley mechanical engineer and principal investigator on the work, "generating 1 Watt of power requires about 3 Watts of heat input and involves dumping the heat equivalent of about 2 Watts into the environment. If even a fraction of the lost heat could be converted into electricity in cost-effective fashion, the impact on the electric power industry would be enormous. It would produce massive savings of fuel and huge reductions in carbon dioxide emissions."

For 50 years, scientists have explored the Seebeck effect, a phenomenon in which voltage is created when the junctions of two different metals are kept at different temperatures. But tabletop thermoelectric generators of this sort operate at a puny 7% efficiency, compared with 20% for conventional heat engines.

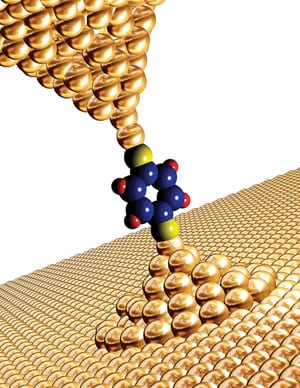

The new UC Berkeley research, according to a university press release, "marks the first time the Seebeck effect has been measured in an organic molecule, laying the groundwork for more cost-effective thermoelectric converters." The researchers coated two gold electrodes with molecules of benzenedithiol, dibenzenedithiol, or tribenzenedithiol, and then heated one site to create a temperature differential (Figure 2).

|

2. Gold standard. A depiction of an organic molecule trapped between two gold surfaces. Creating a temperature difference between the two metal sides produces a voltage and current. Courtesy: University of California, Berkeley

|

For each degree Celsius of temperature difference, the researchers measured 8.7 microvolts for benzenedithiol, 12.9 microvolts for dibenzenedithiol, and 14.2 microvolts for tribenzenedithiol. The maximum temperature differential created was 30 degrees C.

"The effect may seem quite small now," said graduate student Pramod Reddy, "but this is a significant proof of concept and the first step in organic molecular thermoelectricity." Majumdar added, "we are going down the road of cheap thermoelectric materials. The use of inexpensive organic molecules and metal nanoparticles offers the promise of low-cost, plastic-like power generators and refrigerators."

The next steps, say the researchers, will include testing different organic molecules and metals, and fine-tuning the assembly of the structure.

Rinspeed’s roadster: Fast, fun, and green

How do you build a car that’s both powerful and low in carbon dioxide emissions? For Swiss car designer Rinspeed and Germany’s Bayer MaterialScience AG, the answer is diet and exercise. The two companies have teamed up to produce the Rinspeed eXasis (Figure 3). The vehicle mounts a lightweight, high-output Weber 750-cc (49 cubic inch), two-cylinder engine on a frame made of Bayer’s Makrolon polycarbonate.

|

3. Horse and biobuggy. Weighing in at 1,650 pounds, this roadster can accelerate from 0 to 60 mph in less than 5 seconds and hit a top speed of 131 mph, all while burning E85 and producing minimal CO2 emissions. Can going green be fun? You bet. Courtesy: Rinspeed

|

The result is a 1,650-lb roadster with 150 brake horsepower and a 210 km/hour (131 mph) top speed that can go from 0 to 60 mph in less than 5 seconds burning E85 ethanol. Carbon dioxide emissions are only 20 grams/kilometer, compared with 200 grams for a conventional midsize car.

"Cars must become even lighter to save CO2, and there’s no way of doing that without modern plastics," says Rinspeed chief, Frank M. Rinderknecht. "Environmentally friendly cars cannot be seen as an exercise in self-denial. On the contrary, they must be fun, or no one will buy them." The eXasis is the third concept vehicle for Rinspeed and Bayer.

Urs Wenger, of engine-maker Weber’s development partner, swissauto, added, "The eXasis propulsion system represents downsizing in its purest form. We have dispensed with not only the huge-capacity engine, but also some of the cylinders. Why? In this way, we can retain the desirable small engine capacity while keeping the more-efficient, large-volume cylinders."

The fuel for the eXasis project comes from Alcosuisse, the for-profit arm of the Swiss Alcohol Board, which is researching bioethanol. The Swiss Federal Office of Energy has picked the eXasis for a study on lightweight construction and ecology. According to the Swiss energy agency, reducing vehicle mass is the most effective way to lower fuel consumption.

Dead chickens, the weirdest renewable

United Press International, quoting the Swedish newspaper Västerbottens-Kuriren, reports that Umea Energi, a Swedish utility, is using chicken carcasses from local egg farms to fuel an existing waste-to-energy plant.

The utility, in far northern Sweden, incinerates waste to produce both electricity and district heat for Umea, a city of 110,000. A company spokesman noted that "chickens are just the right size" (Figure 4) for the conveyor belt that feeds the plant. The company added that it has plenty of nonpoultry fuel for the plant and is taking the chickens as a favor to the egg farmers.

|

4. Poultry power. Dead or alive, chickens—such as this small farm flock hen—may cross the road into renewable fuel territory. Courtesy: Carolyn Maize

|

Although Umea Energi appears to be unique in using chickens as fuel, there is plenty of interest in the U.S. in poultry-related fuels. The 2005 Energy Policy Act includes subsidies for studies of the feasibility of using chicken litter as a fuel.

According to the Physorg.com science web site, the Gas Technology Institute (GTI) has demonstrated that chicken litter can be gasified to produce hydrogen for fueling a solid-oxide fuel cell. Working at the University of Georgia, and funded by the U.S. Department of Agriculture, GTI operated a bench-scale fluidized bed gasifier at 1,550F to turn litter into low-Btu syngas. The researchers used a zinc-oxide bed to remove H2S from the gas before it enters the fuel cell.

In late 2005, the Associated Press reported that researchers at the University of Arkansas have a schmaltzy approach to chicken-based fuel. They have developed a way to convert chicken fat into biodiesel. Chemical engineering professor R.E. Babcock said chicken-fat fuels "burn better, create less particulate matter, and actually lubricate and clean things like cylinders, pistons, and fuel lines." Chicken fat also is cheaper than soybean oil, the usual source of biodiesel.

Siemens celebrating three big deals

Siemens Power Generation (www.powergeneration.siemens.com) has won a $450 million contract to supply the turbines and O&M for the 350-MW Caithness Long Island Energy Center, a gas-fired, combined-cycle project. The plant, being developed by New York–based independent power producer Caithness Energy LLC, will provide power to the Long Island Power Authority (LIPA).

The Caithness project will be sited in Brookhaven, N.Y., in an existing industrial park. According to LIPA, it will be the first sizable power plant built on Long Island in more than 30 years. Nassau and Suffolk Counties have a combined population of 2.8 million.

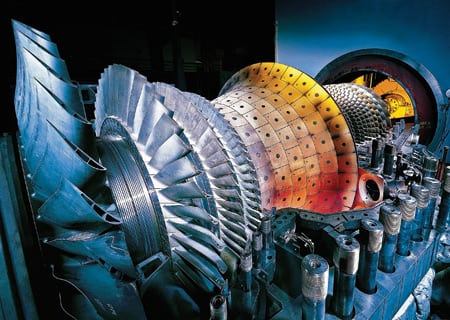

"Siemens is playing an instrumental role in helping to meet the increasing energy demands of Long Island with its state-of-the-art gas turbine technology that will provide competitive, environmentally compatible energy to the residents of Brookhaven," said Randy Swirn, CEO of Siemens Power Generation Inc. His firm will be supplying a SGT6-5000F gas turbine (Figure 5) and an SST-900 RH steam turbine to the project. Siemens will also handle operations and maintenance of the plant for 17 years.

|

5. Start of the cycle. A Siemens gas turbine like this one will be the primary energy converter of the Caithness Long Island Energy Center, a 350-MW gas-fired combined-cycle project. Courtesy: Siemens Power Generation

|

In other news out of Erlangen, Siemens Power Generation has been picked to supply 54 wind turbines for two offshore wind farms in Britain. The turbines, with a total capacity of 180 MW, will power the Lynn and Inner Dowsing projects near Lincolnshire, on the east coast. According to Siemens, this will be the second time that its 3.6-MW model will be deployed offshore.

The purchaser is Centrica, the parent of British Gas. Siemens will also perform O&M on the projects for five years. Siemens said the order is part of an overall investment of about $580 million.

Siemens Wind Power has two ongoing offshore projects: in Lillgrund, Sweden, and Burbo Banks, in Liverpool Bay on Britain’s west coast (Figure 6). Both projects are scheduled for commissioning later this year. The Lynn and Inner Dowsing projects are scheduled to begin service by the end of 2008.

|

6. Doubled demand. Siemens supplied the turbines for two offshore wind projects already in place, and soon will do likewise for two recently announced UK projects with a total capacity of 180 MW. Courtesy: Siemens Power Generation

|

"Last year, we doubled our turnover, and our declared objective is still to make our wind power business grow faster than the market," said Andreas Nauen, CEO of Siemens’ wind business. "Securing the two projects in Britain will bring us a good step forward in this respect. They will help us advance our leading position in the growth market of offshore wind farms."

A month earlier, Siemens announced that it had landed a $662 million deal to build a turnkey 840-MW combined-cycle plant in the UK. The company will supply two SGTF-4000F gas turbines, one SST6-5000 steam turbine, and three generators. The owner of the plant is Marchwood Power Ltd., a 50-50 joint venture of ESBI and Scottish & Southern Energy Plc. It will be located in the vicinity of Southhampton on England’s south coast.

Nevada Power picks P&W, CH2M Hill

Nevada Power Co. has awarded Pratt & Whitney Power Systems (www.pw.utc.com) a contract to supply twelve 60-MW FT8 Swiftpac gas turbines that will increase the peaking capacity of Clark Station in Las Vegas. Financial terms of the deal were not disclosed.

The utility, a subsidiary of Sierra Pacific Resources, has hired CH2M Hill (www.ch2m.com) to handle the project’s engineering, procurement, and construction. The first 400 MW of the capacity expansion is scheduled to be completed before the 2008 summer peak, with the remainder following by the end of the year.

Pratt & Whitney (P&W), a subsidiary of United Technologies, says the first Swiftpac turbine is scheduled for delivery this October, with the full dozen scheduled for arrival by next summer. Said Peter Christman, president of P&W Power Systems, "The Swiftpac has a successful track record of providing reliable and environmentally friendly peaking power. The turbines will be a low-cost solution to southern Nevada’s burgeoning demand growth."

The FT8 (Figure 7) is derived from P&W’s JT8D jet aircraft engine, a workhorse of the worldwide aviation fleet. More than 4,500 aircraft, or one-third of the global commercial fleet, are powered by the JT8D, according to P&W.

|

7. Like father, like son. This Pratt & Whitney JT8D aircraft engine, popular with airlines, is the forerunner of the FT8 Swiftpac for stationary power generation. Courtesy: Pratt & Whitney

|

The FT8 has been updated with technologies that can produce power with less noise and lower emissions and at a higher efficiency, says the company. The FT8 has been in production since 1991 and operates at more than 70 sites, with more than 300 units installed or on order. With a reported reliability of greater than 98%, the machines have accumulated more than 2 million hours of operation.

Scuderi’s air-hybrid engine

A Massachusetts firm it says it will begin licensing for power generation applications a hybrid internal combustion engine suitable for small commercial and industrial use.

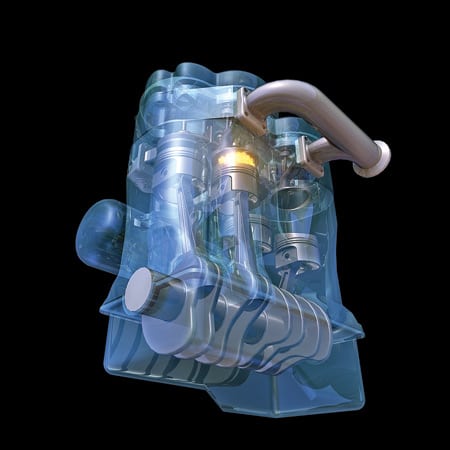

Scuderi Group LLC (www.scuderigroup.com) says its air-hybrid machine (Figure 8) "can provide significantly increased efficiency levels while dramatically decreasing the levels of toxic emissions." Scuderi calls its technology "split-cycle" and describes it as "dividing the four strokes of the Otto cycle over a paired combination of one compression cylinder and one power cylinder. Gas is compressed in the compression cylinder and transferred to the power cylinder through a gas passage.

|

8. Two-banger. Scuderi Group claims that this cross-fired "air-hybrid" internal combustion engine is ideal for small power producers. The key to the technology is the exchange of air from cylinder to cylinder during the compression and exhaust strokes of the four-stroke Otto cycle. Courtesy: Scuderi Group

|

"The gas passage includes a set of uniquely timed valves, which maintain a precharged pressure through all four strokes of the cycle. Shortly after the piston in the power cylinder reaches top dead center, the gas is quickly transferred to the power cylinder and fired to produce the power stroke."

Sal Scuderi, president of the company, said, "Small factories and power plants now have a brand-new option for generating power with far less fuel and lower pollutant emissions." He explained that the duty cycle of a stationary generating plant is less stringent than that of a mobile application, such as an auto engine. Because generators "run at narrower speed and load ranges," according to Scuderi, the advantages of his engine—faster flame speed, lower NOx production, and higher efficiency—come into play.

Scuderi says it expects the first prototypes this year. The design is patented. Scuderi Group’s business is based on the work of the late Carmelo Scuderi (1925–2002), who invented the oil-less compressor that significantly changed the refrigeration and air-conditioning markets. His work, including the air-hybrid engine, was featured in an August 2006 broadcast of the American Public Media show, Marketplace.

Ovation for huge new Chinese coal plant

The 1,000-MW Units 1 and 2 of the new, four-unit Huaneng Yuhan power plant in China have implemented expert control systems from Emerson Process Management (www.emersonprocess.com). Emerson, a major supplier of process controls to the electric power, water treatment, and wastewater industries, won the $7 million contract for the systems in April 2005.

The 4,000-MW plant, owned by Huaneng Power International, is the first to implement 1,000-MW ultrasupercritical technology in China. Emerson reports that Unit 1 completed its 168-hour performance test last November, and that Unit 2 was synchronized to the grid the following month. An Ovation expert system (Figure 9) monitors and controls the units’ data acquisition system, modulating control system, sequence control system, furnace safeguard supervisory system, and major energy converters such as the boiler, turbine, and generator.

|

9. Megawatt maven. An Ovation expert system like this one is now controlling two of the four 1,000-MW units of a new, ultrasupercritical temperature and pressure coal-fired plant in Yuhan, China. Courtesy: Emerson Process Management

|

Emerson says its Ovation control system was designed specifically for the power generation business and has been used in thousands of installations. According to the company, the Chinese ultrasupercritical units at Yuhan "are currently the cleanest, most efficient, and most advanced in the world." Their reported 45% thermal efficiency compares favorably with the 30% to 38% efficiency of plants operating at subcritical temperatures and pressures.

PG&E dips toe into wave power

Pacific Gas and Electric Co. has filed with the Federal Energy Regulatory Commission (FERC) two preliminary permit applications for wave energy projects to be sited off the California coast.

"The waters west of Humboldt and Mendocino counties have excellent wave power potential," said Fong Wan, PG&E’s vice president of energy procurement. "The development of this new type of energy resource, which generates electricity from the movement of water near the surface of the ocean, is one of the many sources of clean, non-polluting, renewable energy that PG&E is aggressively pursuing."

Most of the wave energy conversion (WEC) devices that PG&E is considering for its "WaveConnect" program float on the ocean surface and generate electricity from the movement of waves. As lead developer, PG&E says it will be responsible for site permitting and "will encourage the participation of multiple WEC device manufacturers in the projects."

According to PG&E, its WaveConnect program would be the first in North America "to allow multiple WEC device manufacturers to demonstrate their devices on a common site, which could help accelerate the development of wave energy technology." The timing of the program could not be better. This February, FERC issued a notice asking for comments on how the agency should process applications for ocean-based generating technologies. FERC Chairman Joseph T. Kelliher said, "These emerging new hydroelectric technologies have significant potential. However, [they] present some challenges relating to reliability, environmental and safety implications, and commercial viability."

PG&E said that if technical results look good, it would pursue "phased development" of the two wave power sites. The projects would move ahead, the San Francisco–based utility said, only if "technical results support feasibility, environmental studies show that any significant impacts can be fully mitigated, and stakeholder considerations can be satisfactorily addressed."

POWER digest

News items of interest to power industry professionals.

FuelCell Energy gets CARB certification. The California Air Resources Board has certified that FuelCell Energy‘s new 300-kW DFC300MA molten carbonate fuel cell meets the state’s distributed energy generation emission standards for 2007. The CARB earlier approved a FuelCell Energy machine that can produce 250 kW of power.

Connecticut-based FuelCell Energy (www.fce.com) says it will begin shipping the new units in the second quarter of this year. Because fuel cells are classified as "ultra-clean" technology, they are exempt from the permitting requirements of California’s local air quality districts

"California is one of the largest power consumers in the world," said William Karambelas, a FuelCell Energy executive, "so it is critical for us to design products that meet its requirements. With this certification, we once again demonstrate our corporate commitment to delivering ultra-clean, efficient power plants. We significantly increased the output of the DFC300MA while reducing production costs and maintaining our low emission standards."

California’s Self-Generation Program, a state-supported subsidy, provides over $80 million per year in incentives to renewable and ultraclean generating technologies. According to FuelCell Energy, the state support amounts to $2,500/kW for its products that burn natural gas and $4,500/kW for units fueled by renewable resources such as methane from landfill and water treatment plants.

GE, Toshiba extend turbine services venture. GE Energy and Toshiba have extended their gas turbine services joint venture to include GE’s H System machines, the most advanced gas turbine combined-cycle equipment that the company markets.

Toshiba-GE Turbine Services Co. (TGTS) was formed in 1996 to serve customers in Japan that operate GE-designed 50- and 60-Hz E- and F-class gas turbines. When the companies recently renewed their joint venture agreement, they added the H-class machines. Said John Reinker, GE’s manager of heavy-duty turbines and combined-cycle products, "The original purpose of the TGTS joint venture was to provide our Japanese customers with faster turn-around times and higher-quality gas turbine components and services." He noted that by adding the H-class equipment, "we are further expanding the scope of services that we can offer customers."

GE notes that three 50-Hz, 9H systems soon will be installed in Japan, at Tokyo Electric Power Co.‘s Futtsu station Group 4. GE shipped the first unit in June 2006. According to GE, the H system is the first and only combined-cycle technology in the world to have broken the 60% thermal efficiency barrier.