One of the main criticisms of renewable energy facilities is that they are unable to dispatch electricity when it’s needed. The great game-changer is low-cost energy storage, which would enable renewable energy production to be stored and rapidly released when needed. Here are seven promising distributed energy storage technologies that could be commercialized in the near future.

The electricity industry has enabled customers to expect that their lights will turn on with each flip of the switch. Hidden behind that switch is an enormously complex machine of transmission and distribution wires, substations, and a network of power plants that must respond, immediately, with the electricity required to operate those bulbs. Add up the myriad requests by millions of consumers over a typical day and the synchronicity of demand and supply is astounding.

Even less appreciated is the human element that controls the machine’s daily operation. The technology behind dispatching a strictly fossil-fuel and nuclear fleet has been well-honed over many years by utility engineers. Today, modern automatic generation control systems can quickly respond to commands of a single dispatcher responsible for continuously balancing electricity supply and demand for those millions of customers—a necessity, as storing any appreciable quantity of electricity is impractical today.

It’s Complicated

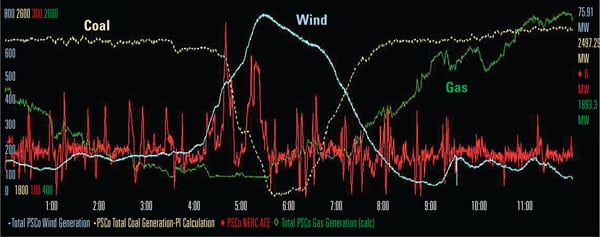

Adding intermittent renewable sources in small quantities to the grid, as has occurred over the past decade, has made the dispatcher’s job much more complex. Accurately predicting the amount of wind or solar generation tomorrow, or even an hour from now, in order to balance electricity supply and demand, is problematic (Figure 1). Ask the typical dispatcher (as I did during a recent tour of a Midwestern utility’s dispatch center) what new tools would make his job easier, and the answer is invariably: “Give me electricity that can be connected to the grid at the touch of a button.” Today, with the exception of the 10 pumped storage plants in the U.S. and a single compressed air energy storage facility, bulk electricity storage remains a fictional technology. But all that is about to change, as the discussion of emerging technologies below shows. (See also “Bulk Storage Could Optimize Renewable Energy,” in POWER’ s September 2010 issue or in the online archives at https://www.powermag.com.)

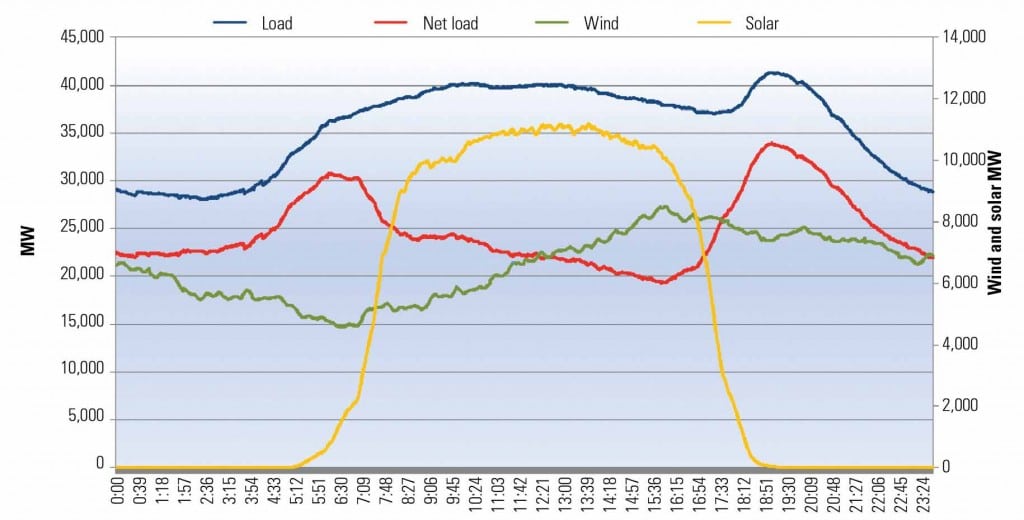

|

| 1. Tough balancing act. Public Service Co. of Colorado (PSCo), an Xcel Energy company, has been aggressively adding wind power to its system for the past few years. The data in this figure, captured for July 2, 2008, illustrate how the variable nature of wind-produced electricity can affect the dispatching of fossil plant resources. Early in the morning, coal was providing baseload electricity (yellow) while gas-fired assets (green) were load-following. The blue line shows wind generation. The red line is the NERC-defined Area Control Error (ACE), which represents, in essence, the difference between supply and demand. Note how the morning increasing wind forced PSCo’s coal plants to minimum load. Wind then quickly dropped between 7 and 8 a.m. and almost disappeared by mid-morning, forcing both coal- and gas-fired plants to quickly ramp up to match the lost wind load and meet the rapidly rising summer day demand. Wind was essentially absent during the peak demand period. An effective form of energy storage would eliminate these large and inefficient load swings and the system disturbances they cause. Source: PSCo |

In the interim, dispatchers have learned to manage the unpredictable side of renewable generation, usually by keeping sufficient spinning reserve capacity at the ready to cover any eventuality. Utilities have also upgraded ramp rates (the rate that electricity production can be increased or decreased) on existing fossil plants, added automatic generation controls for remote control of the faster-responding units, and installed fast-acting simple-cycle combustion turbines (see “Flexible Turbine Operation Is Vital for a Robust Grid,” September 2010) or reciprocating engines (see “Top Plants: Goodman Energy Center,” September 2009) in some regions. These technologies provide even faster response during periods when intermittent renewables were predicted to generate electricity but didn’t, or in regions where market conditions place wind first in the dispatch order.

But these technical improvements in existing equipment are merely stopgap measures for many regions that have plans to add even more renewables to the grid. California, for example, is mandated to have 33% renewable use by 2020; Colorado’s renewable portfolio standard goal is 30% by 2020. By 2020, fewer, faster fossil plants will be under the control of the California Independent System Operator, so they will not alleviate grid reliability concerns, especially given the large amount of imported energy the Golden State relies on. And the U.S. nuclear fleet, in general, is not designed for load-following or cycling operation, so that option is off the table.

While dispatchers are grappling with these new grid realities, the grid machine continues to evolve. In the future, dispatchers will be asked to manage a much more diverse power generation system consisting of many more variable electricity producers on the supply side and even more behind-the-meter distributed resources, such as rooftop photovoltaics, on the demand side (see p. 46, “The Smart Grid and Distributed Generation: Better Together”). Bulk quantities of electricity from larger wind farms will continue to increase (although at a slower rate in the future) while the wind turbine technologies they use promise to become more efficient (see p. 38, “Changing Winds: The Evolving Wind Turbine”).

The politics of renewable energy incentives play a large role in determining which plants will be dispatched, yet there’s no accounting for the hidden costs to the fossil fleet. For example, it’s now common practice in the Electric Reliability Council of Texas (ERCOT) for wind generators to sell electricity at negative prices—owners are paying ERCOT to take the energy—in order to qualify for a production tax credit that is based on megawatt-hours produced. During the summer months, off-peak wind is replacing gas-fired generation in ERCOT and disrupting the market, even when natural gas prices are low. The problem was exacerbated by the average wholesale price of electricity dropping as much as 50% in some regions of the U.S. over the past year.

Another complication is that energy storage rules and regulations are in their infancy; only a single state-required energy storage law is on the books. On September 29, 2010, California Governor Arnold Schwarzenegger signed AB 2514, the Energy Storage Bill, into law. According to the California Public Utilities Commission, the next step is to “open a proceeding to determine appropriate targets, if any, for each load-serving entity to procure viable and cost-effective energy storage systems.”

The new California law requires utilities to obtain 2.25% of their peak power from storage systems by 2014 and 5% of their peak power from storage by 2020. Perhaps this renewed interest in energy storage will breathe new life into the moribund 500-MW Lake Elsinore Advanced Pump Storage Project that has been under development in southern California since 1987.

The problem of balancing renewable generation with other environmental demands is also forcing some utilities to make tough decisions. A good example is when very high water flows in the Columbia River, as are being experienced this year, reach Bonneville Power Administration (BPA) hydro plants. Coincident with high hydroelectricity production is the production of enormous amounts of power from wind farms that have been installed in the region. In fact, total hydroelectric and wind generation exceeds grid demand during certain times of the year. When grid demand is low, BPA’s choice is to either bypass dam generators or reduce wind energy purchases. But excessive flows through the dam bypass (required when hydropower is curtailed but the water flows continue) damage salmon and other fish species, violating Endangered Species and Clean Water Act requirements placed on the hydro plants. BPA has proposed a program of “environmental dispatching,” whereby the hydro dams are dispatched first to ensure all environmental operating standards are met and wind generators get the remainder of the load. BPA is expected to release its final plan on April 1.

These energy supply timing problems have other significant consequences for grid management. For example, for planning and dispatching purposes, ERCOT assumes that only 8.7% of all the wind power generated in Texas will be available to meet on-peak power demand. The uncertain and variable output from renewables also makes these energy sources unsuitable for providing contingency spinning reserve, load-leveling arbitrage (moving electricity production from off-peak to on-peak hours), and regulation services (including black start and VAR support), which are vital to reliable grid operation. These basic grid services (called ancillary services in some regions) are critical for reliable grid operation and are costly to provide. Whether those costs should be shared by all electricity users or by all electricity providers remains a topic of heated debate.

Meeting the Technical Challenge

This litany of problems is, in essence, all about matching renewable generation with a grid built for fossil generation. Setting aside the grid services requirements for a moment, it seems the issue is not the amount of renewable generation that could potentially be generated, from wind for example, but one of timing. The conclusion seems obvious: Some form of electricity storage technology must be added to the future power grid. If generation produced off-peak, such as when the wind blows in Texas, could be collected, stored, and later released on the dispatcher’s order, then many of the criticisms of renewables would be eliminated, the costs of bulk electricity storage notwithstanding.

Electricity storage is a technical problem that can be solved—if given the necessary resources. Unfortunately, the incentives provided to renewable electricity generators over the years were not available to designers of bulk electricity storage, and a wide technology deployment gap now exists. The total U.S. Department of Energy (DOE) 2012 budget request of $57 million for grid-scale energy storage projects is an increase of $43.4 million over the 2010 request, but it will take a long time and millions more for energy storage to catch up with renewable technologies’ research and development (R&D). (It should also be noted that $64.5 million in American Recovery and Reinvestment Act funds were paid out in grants to energy storage–related projects.)

FERC Commissioner Philip Moeller, speaking recently at the Silicon Valley Energy Storage Symposium, summed it up this way: “Energy storage is a matter of when, not if.” Indeed, privately funded firms are now carrying the work forward. Moeller also noted that the BPA system in the Pacific Northwest “absolutely needs storage because of the level of penetration of wind in the region.”

It’s somewhat satisfying to remember that technology breakthroughs can’t be planned and often come at the most unexpected times. Do you remember December 2005, when natural gas hit a historic high price of $15.38 per million Btu and developers were rushing around trying to build new liquefied natural gas (LNG) terminals to handle the predicted rise in imports? Rapid advances in well drilling technology, funded solely by private industry, were the unexpected game-changer. By mid-February 2011, the price of natural gas was hovering around $4.30 and estimated recoverable reserves promise to keep us awash in natural gas for a century (ignoring the even greater amounts of natural gas available beneath the Outer Continental Shelf that are now off limits). And what of those two dozen new LNG terminals seeking permits just five years ago? Today, existing LNG terminals are pursuing conversions to handle exports, not imports. This one technology advancement, unimagined five years ago, has touched every corner of our economy.

In my opinion, utility-scale electricity storage technology will reach prime time within the next five years. Mind you, the low cost of natural gas does dampen enthusiasm for private industry energy storage R&D, but the benefits of being on the leading edge of the technology deployment of a predicted $200 billion business can’t be overlooked. Economical, bulk electricity storage technologies would be a game-changer for the power generation industry in ways we can’t envision today. My research found a number of unique technologies under development that could be deployed in a matter of a few years.

All of the following options are technically feasible and are included here because of their unique yet simple design, the promise of reasonable installation costs, and a less-than-five-year development horizon. You’ll notice that no advanced battery technologies are included on the list for one simple reason: There are dozens of companies involved in advancing several battery technologies and pilot projects, but few are truly utility-scale. Some might argue that electric vehicles on a smart grid are a distributed energy storage resource, and they would be conceptually correct. But deployment at utility scale is unlikely to take place within five years, so vehicle energy storage didn’t make the cut.

Electricity as Natural Gas

Solutions to the electricity storage dilemma are moving forward on many fronts. One interesting technology, proposed by a German-Austrian R&D team, is to take renewable electricity and transform it into gaseous methane that can be stored in existing facilities and transported in existing natural gas pipelines.

The process was developed by the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), in cooperation with the Fraunhofer Institute for Wind Energy and Energy System Technology IWES. Currently, Solar Fuel Technology, the Austria-based partner company, is responsible for commercializing the energy storage system.

The process of producing natural gas combines the separate technologies of hydrogen electrolysis and methanation. “Our demonstration system in Stuttgart separates water from surplus renewable energy using electrolysis. The result is hydrogen and oxygen,” explains Dr. Michael Specht of ZSW. “A chemical reaction of hydrogen with carbon dioxide generates methane—and that is nothing other than natural gas, produced synthetically.”

At this time, a 30-kW demonstration system built on behalf of Solar Fuel Technology in Stuttgart is already operating successfully. By 2012, a substantially larger system—rated at about 10 MW—is scheduled to be launched.

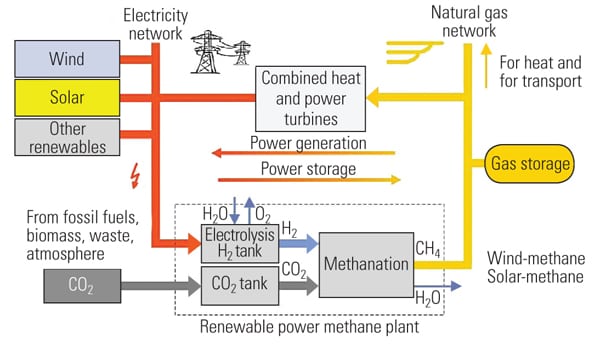

This process has a claimed efficiency of more than 60%, the product of the electricity-to-hydrogen electrolysis process efficiency (75%) and the hydrogen-to-methane or methanation process efficiency (about 80%). Figure 2 illustrates the energy conversion process.

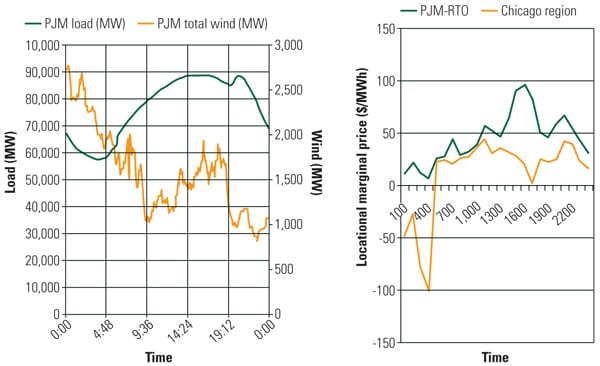

|

| 2. Two-step process. A team of German and Austrian researchers proposes producing natural gas in a two-step process: electrolysis of water using surplus wind or solar energy followed by methanation of the hydrogen with carbon dioxide to produce a synthetic natural gas. The natural gas would then be added to the existing system of pipelines, effectively storing the gas. Source: Center for Solar Energy and Hydrogen Research Baden-Württemberg |

“So far, we converted gas into electricity [today, in conventional power plants]. Now we also think in the opposite direction, and convert electricity into ‘real natural’ gas,” explains Dr. Michael Sterner of Fraunhofer IWES, who is investigating engineering aspects and energy system analysis of the process. “Surplus wind and solar energy can be stored in this manner. During times of high wind speeds, wind turbines generate more power than is currently needed. This surplus energy is being more frequently reflected at the power exchange market through negative electricity prices.”

“Within the development of this technology, ZSW has been guided by two core issues,” explains Specht: “Which storage systems offer sufficient capacity for fluctuating renewable energies that depend on the wind and weather? And which storage systems can be integrated into the existing infrastructure the easiest?” The answer is to use what’s already available.

To illustrate the enormous volume of the natural gas network in Germany, Specht uses the following conversion: The gas pipeline network holds the energy equivalent of more than 200 terawatt-hours—enough to satisfy electricity consumption for several months. The electricity grid has can store only 0.04 terawatt-hours by itself. The ability to leverage the existing natural gas supply network, pipelines, and storage systems for electricity storage is a very elegant solution.

Electrolyzed Water with CO2

Other startup companies are exploring similar chemical processes that could be adapted for electricity storage. Doty Energy is pursuing an approach similar to ZSW’s to produce synthetic fuels in a process it calls WindFuels. Doty proposes to use off-peak wind energy to produce fuels such as gasoline and diesel from carbon dioxide (CO2) and water. Electricity is used in an electrolysis process to break the molecular bond of water to form hydrogen (H2) and oxygen (O2). The hydrogen is then combined with CO2 in a reverse water gas shift reaction to reform CO2 into H2O and carbon monoxide (CO). Finally, the CO and H2 are chemically reformed into liquid hydrocarbon products in a process Doty Energy calls a Renewable Fisher Tropsch Synthesis system.

The overall conversion efficiency is on the order of 60% based on this combination of processes with a long history in the chemical process industry. Doty Energy states that WindFuels are economic with oil prices above $80/barrel and off-peak energy at $16/MWh. The company is currently looking for funding for a first demonstration project.

Electricity as Compressed Air

Compressed air energy storage (CAES) has long been recognized as an effective means of storing electricity generated off-peak that can be released during high-electricity-demand periods. The technology has been well-thought-out since the early 1960s, when combustion turbine technology progressed to the point where the system was technically feasible. However, plant construction has not advanced nearly as far as the technology. Today, there are only two systems in commercial operation: The 290-MW Huntorf plant in Germany that entered service in 1978 and the 110-MW Alabama Electric Corp. plant in McIntosh, Ala., commissioned in 1991.

Many other sites have been identified by developers as potential CAES candidates, but no projects are close to construction at this time. (See “The Return of Compressed Air Energy Storage,” October 2008 and “Could CAES Answer Wind Reliability Concerns?” December 2010 for the technical details of a typical CAES system.)

After more than 20 years of CAES design and construction inactivity, the Thayer School of Engineering at Dartmouth College in 2007 developed a modernized and more efficient CAES plant design. The college has recently spun off a development company called SustainX, supported by funding from the National Science Foundation Small Business Innovation Research Program plus equity investments from Polaris Venture Partners, Rockport Capital, and General Electric, as part of its GE Ecomagination Challenge.

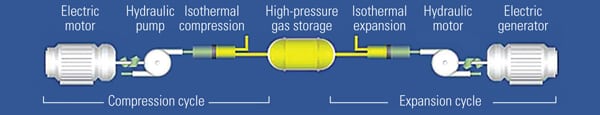

The new approach, which SustainX calls ICAES (isothermal compressed-air energy storage), uses electrical energy to compress air near-isothermally, stores it aboveground in commercial gas storage facilities, and expands it near-isothermally to generate electricity using no fossil fuels. To store energy, SustainX uses off-peak wind energy electricity, for example, to drive a reciprocating compressor outfitted with a water spray to keep the air at a constant temperature during compression from atmospheric pressure up to a maximum of 3,000 psig. During compression, the sprayed water absorbs heat from the air, effectively improving the compression efficiency. The compressed air is then stored in aboveground storage vessels and the heated water is stored in a constant-temperature reservoir (Figure 3).

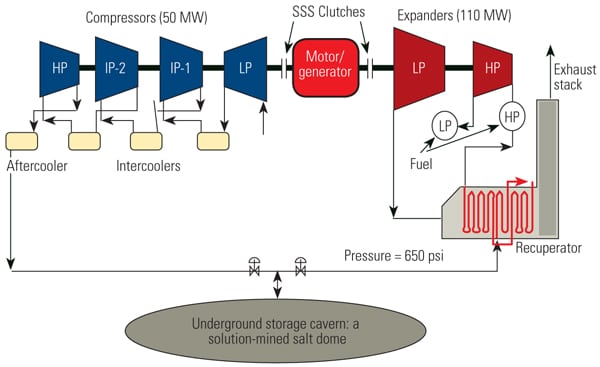

|

| 3. Aboveground compressed air storage. A key enabler of the SustainX technology is isothermal (constant temperature) compression and expansion of the gas rather than the adiabatic (no heat transfer) processes used by other CAES techniques. Thermal efficiencies in excess of 90% have been achieved experimentally by SustainX, compared with ~50% thermodynamic efficiencies for adiabatic techniques over the same pressure range. Source: SustainX |

The developers estimate a seven-fold reduction in storage costs compared with conventional CAES, which is not surprising, because there is no massive solution-mined salt dome to construct. To produce energy from aboveground storage, compressed air is used to drive the same compressor in reverse, which in turn drives an electric generator. Warm water from the reservoir is sprayed into the air during expansion to keep the air from cooling. Keeping the air at a constant temperature during compression, storage, and expansion yields a more efficient storage cycle.

In a November 23, 2010, interview with Smart Grid Today, SustainX CEO Tom Zarrella estimated that the electricity storage market will grow to a $200 billion business in coming years. Zarrella also noted that the SustainX technology approach could cost less than half as much as traditional CAES systems because it “does not have to be paired with a secondary heat source such as a combustion turbine.” The SustainX design generates electricity directly from the expansion of the compressed gas itself, without any external fuel source. The big advantage is that any aboveground gas storage facility can be used, eliminating the requirement for conventional CAES to be adjacent to a large underground salt cavern.

SustainX announced in November 2010 that the company will bring its technology to market in 2012, although the particulars of the first project were not revealed.

Electricity as Thermal Energy

A number of R&D development paths have as a primary goal the storage of thermal energy as an electricity equivalent. The main differences between the technologies are whether the thermal energy is stored as low-temperature ice or in higher-temperature forms of energy.

One interesting low-temperature technology is distributed ice-based energy storage that uses less-expensive off-peak electricity to produce and store thermal energy for use during peak demand periods. The ice-production technology is familiar and has been around for many years. What’s unique is that ice production and conventional air conditioners have been combined into a single system. And it is just recently that the technology has reached utility scale.

Ice Energy is currently constructing a 53-MW project, the largest ice-based energy storage project of its kind, for the Southern California Public Power Authority (SCPPA), a joint powers authority consisting of 10 municipal utilities and one irrigation district. The goal is to “permanently reduce California’s peak energy demand by shifting as much as 64 gigawatt hours of on-peak electrical consumption to off-peak periods every year, reducing exposure to costly peak power and improving the reliability of the electrical grid,” according to a company fact sheet.

The project is called “distributed” because it consists of more than 6,500 “Ice Bear” energy storage units installed at approximately 2,000 sites throughout Southern California. Each ice storage unit operates in tandem with a standard air conditioning unit. It essentially replaces on-peak electricity demand, when air conditioning is usually required, with up to six hours of air conditioning provided by melting ice that was produced using off-peak electricity. Ice Energy states that daytime energy demand from air conditioning—typically 40% to 50% of an average commercial building’s electricity use during peak hours—can be reduced by as much as 95%.

According to the SCPPA, all the systems can be centrally controlled to “provide a single manageable utility-scale resource that can permanently reshape system load.” The units are being installed over a 24-month period that began in mid-2010.

Underground Pumped Storage

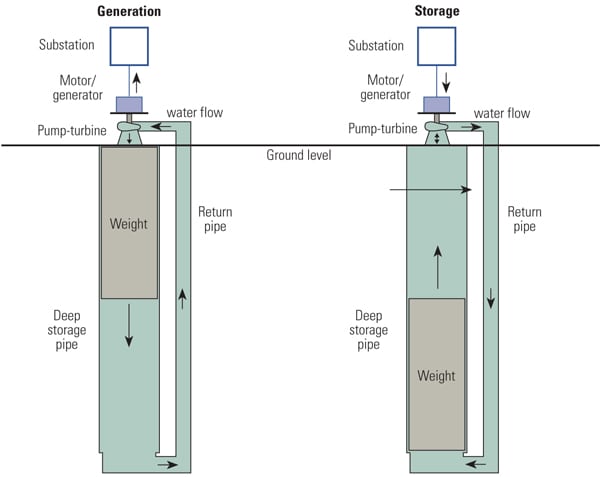

Gravity Power, an energy storage spin-off of LaunchPoint Technologies, is proposing to avoid the resistance to constructing conventional pumped hydro storage facilities by going underground. CEO Jim Fiske says that by doing so, the company’s proposed Gravity Power Module (GPM) “circumvents most of the problems with pumped storage.”

The concept is brilliant in its simplicity. GPM construction begins with a large borehole drilled straight down into the ground, perhaps thousands of feet for a utility-scale system. At the bottom of the shaft is a large concrete piston fitted to the shaft, called the “weight stack.” Also bored into the ground is a parallel but smaller-diameter “return pipe” that is connected to the main shaft at the top and bottom. Finally, the entire volume is filled with water and tightly sealed—air is compressible and its presence reduces the system effectiveness. In essence, the position of the weight stack in the shaft determines the amount of energy stored.

During the energy storage process, off-peak electricity is used to power a pump that pushes water down the return pipe that will raise the weight stack from the bottom of the deep storage shaft. During a peak electricity demand period, the weight stack is released, which pushes the water up the return pipe, reversing the direction of rotation of the pump-turbine and producing electricity, much as in a typical pumped storage hydroelectric plant (Figure 4).

|

| 4. Pumping weights. Gravity Power proposes boring holes in the ground, perhaps thousands of feet deep, and filling them with water and a large weight. Surplus electricity would be used to raise the weight, creating a form of underground pumped storage. The weight would be dropped during peak periods to produce electricity in a turbine. Source: Gravity Power |

According to Fiske, a 7-acre site can accommodate more than 2 GW of installed power storage, depending on the depth and diameter of the storage shaft. The conversion efficiency of the system is described as in the 75% to 80% range. The installed cost is estimated by the company as around $150/kWh for a system capable of storing about 200 MWh by using a standard pump-turbine design to reduce costs. (The installed cost of a conventional pumped hydro storage facility is around $100/kWh, based on a reservoir capacity of around 10 hours and a first cost of $1,000/kW. Compressed air energy storage is also estimated at about $100/kWh, and this is a capital cost, not a cost of electricity at the meter.) The typical product is envisioned to have a 6-meter (m)-diameter storage shaft and a 2-m-diameter return pipe, 500 m deep, with an 8,000–metric ton storage mass for an 8.5-MWh module. Fiske envisions the systems to be installed in clusters to produce the amount of energy desired.

Development of the GPM appears to be progressing quickly. A small test unit is said to be operating in Santa Barbara, Calif., and the company says a utility-scale project is expected to be online as early as 2013, possibly in Texas, where the geology is ideal. Fiske says that key investors are in place for this project, and there has been much interest in the technology by countries such as China, India, and South Africa, although the U.S. DOE showed little interest.

Pumped Heat Electricity Storage

A potential electricity storage game-changer is United Kingdom startup Isentropic Energy’s proposed Pumped Heat Electricity Storage (PHES) system. Unlike conventional pumped hydro energy storage plants, the PHES system uses a heat pump to store electricity in thermal form or as “pumped heat.”

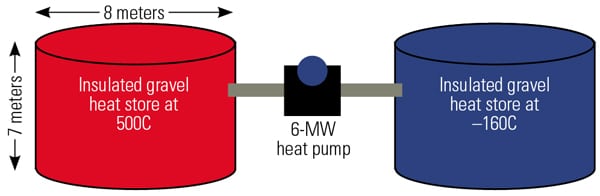

Isentropic Energy’s chief technology officer, Jonathan Howes, describes how the system operates: “The Isentropic PHES system utilizes a highly reversible heat engine/heat pump to pump heat between two insulated storage vessels containing gravel. A gas is employed in this process from which work is extracted. At first, the compressed gas is made to pass through one of the stores. This heat[s] up the gravel up to 500 degree[s] Celsius and during heat exchange, the temperature of the gas almost drops to ambient condition. In the second step, this gas is made to expand to its original pressure and as a result the temperature drops to –160 degree[s] Celsius. It is then passed through the other store and it exchanges heat with the gravel by direct contact. In this process, the gas is warmed back to its original temperature. The energy supply is mainly by employing a motor as it not only supplies electrical power to it but also acts as an energy storage element. The cycle is reversed to release the energy. As the energy passes from hot to cold, it powers a generator from which electricity is produced.” Figure 5 illustrates the concepts.

|

| 5. Cold and hot storage. Isentropic Energy has proposed the simplest of energy storage systems. Two large containers of gravel, one hot (500C) and one cold (–160C) provide the temperature difference to operate a heat pump, based on the Ericsson Cycle. Surplus electricity is used to produce and maintain the temperature in the high-temperature tank by running the heat pump in reverse during times when surplus wind power is available. Source: Isentropic Energy |

The simplicity of the design is extremely attractive. In fact, Howes claims the installed cost of energy storage using the PHES system is currently $55/kWh, dropping to perhaps $10/kWh with utility-scale systems. The overall operating efficiency of the energy storage process is claimed to be 72% to 80%.

The advantages of the system are high power density, being geographically unconstrained, and the fact that the heat pump operates on air, using no refrigerants, chemicals, or water.

The first pilot PHES is targeted at 16 MWh, or 2 MW produced for eight hours.The system can be scaled as required. This pilot system would require a footprint of about 8 m x 16 m x 7 m high. Design of the utility storage prototype is under way and is expected to require about two to two and a half years, according to Howes, but it will require an investment of about $16 million.

Distributed Compressed Air Storage

Professor Seamus Garvey of Nottingham University has proposed combining floating offshore wind turbines and compressed air storage as a cost-effective way to store excess electricity produced by the turbines. A new spin-off company, NIMROD Energy Ltd., has been formed to commercialize the Integrated Compressed Air Renewable Energy System (ICARES) that has been under development since 2006.

The process is simple in concept but requires a new, much larger, and less-expensive fleet of offshore wind turbines to become economic. Wind-produced electricity is used to compress air that is stored in balloons or “Energy Bags” located on the seabed or in geologic formations when deep water is not available. A set of bags is connected to a common compressed air pipe that runs along the seabed. When peaking electricity is required, the compressed air is released from the bags and expanded through a conventional air turbine to produce electricity. During off-peak hours, the energy bags would again be inflated and made ready to repeat the cycle.

The energy bags are to be constructed of a thin polyethylene material that can handle only a 0.4 atmosphere pressure difference. However, in this application the pressure difference is nil because the compressed air in the bag and the external water pressure are in equilibrium. Garvey says that the overall efficiency of the system is about 90%. The design, supported by E.ON, has been successfully tested in laboratory water test tanks. Further prototype testing in seawater is scheduled to begin in May 2011 and is expected to lead into development of a commercial product in the near future.

Thinking big, Garvey says that storing the equivalent of 2 GW for four days will require 7 million cubic meters of air storage. “The optimal dimensions for energy bags are around 20 meters in diameter and each has a volume (when full) of about 4,000 cubic meters,” he says. “For 7 million cubic meters, we would need 1,750 of these bags. The seabed area covered by these would be less than one square kilometer and the total surface area of bag material would be 2.2 million square meters.”

Left unsaid was the how much energy is required to fill the bags in relation to the number of floating wind turbines. Using Garvey’s numbers, it would take about 230 10-MW wind turbines four days to fill the bags, and actually more than twice that time when a reasonable capacity factor for the wind turbines is applied. Garvey is obviously thinking of offshore wind-produced electricity on a much larger scale than is now under development.

Garvey believes that it’s possible to deploy this utility-scale system at a cost well below $16/kWh; that, he says, is less than 20% of the cost for pumped hydro energy. That number also assumes that offshore wind turbines can be scaled up to even larger sizes and that more radical designs can be used to reduce installed costs, by up to a factor of four, by reducing the amount of structural material required per kilowatt of rated power, according to Garvey.

“I foresee that at least 25 per cent of offshore wind power in the UK will use this integrated compressed air approach by 2025,” he says. “Although I expect that the direct-generating wind turbines will catch up with us on cost per unit power output, the role for systems which put energy directly into store is clear. If you have 1 MW of integrated compressed air system (including large energy stores) for every 3 MW of conventional generation, then the whole set of offshore wind equipment starts to look like a very versatile power generating system which can adjust its output to match demand—notwithstanding what the wind is doing.”

Final Thoughts

Each of these technologies is championed primarily by independent entrepreneurs, venture capital firms, many private investors, and several utilities. In contrast, the latest DOE budget request asks for only $34 million for a new Energy Innovation Hub that would focus on “battery and energy storage.” Electricity storage may not be a DOE priority, but commercial utility-scale electricity storage has significant potential, in the short term, to completely reinvent the power generation industry.

— Dr. Robert Peltier, PE is POWER’s editor-in-chief.