Scientists around the world are making progress as they try different techniques to bring commercial fusion energy to fruition.

Much of the discussion about nuclear fusion has long revolved around its promise, which is the potential to create limitless amounts of energy. The reality for this so-called “holy grail” of clean energy, though, has been that it’s always out of reach, with scientists long unable to achieve a substantial “net energy gain” from a fusion reaction—one where the energy output significantly outweighs the energy needed to create that reaction.

That’s changing. Progress is being made, thanks to projects such as the multinational ITER (International Thermonuclear Experimental Reactor) in France, and research at U.S. labs including the National Ignition Facility (NIF) in California, which in 2022 became the first site to achieve ignition. That’s the point where a nuclear fusion reaction becomes self-sustaining, producing more energy than is needed to start and maintain it, creating a net gain of energy—in other words, producing more energy from the fusion reaction than was needed to spark it.

Several companies are involved in research and development projects related to fusion; for many, the goal is to build a commercial-scale fusion power plant. Several of these groups have provided information to POWER about their progress in the fusion space, detailing their projects that would bring a major transformation to the power generation sector.

Commonwealth Fusion Systems

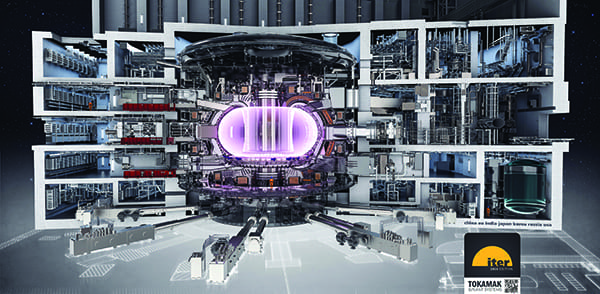

Massachusetts-headquartered Commonwealth Fusion Systems (CFS) has created much of the buzz around commercial fusion energy. Industry experts have said that years of worldwide research have established the tokamak-based configuration as the highest-performing approach to fusion. Many tokamaks built to date have been large in size; CFS is taking a different approach, “using revolutionary high-temperature superconducting [HTS] magnets developed in collaboration with MIT [Massachusetts Institute of Technology] to build smaller and lower-cost tokamak fusion systems,” according to the company.

CFS is manufacturing these magnets, and is building what it calls “the world’s first commercially relevant net energy fusion machine, called SPARC.” The company has said SPARC (Figure 1) will pave the way for the world’s first fusion power plant, called ARC, which is envisioned as a grid-scale fusion power plant in Virginia, with support from Dominion Energy Virginia. CFS said it is working “to design, build, and scale fusion power plants that will deliver cost competitive, clean fusion energy to combat climate change.”

CFS was part of the CES event in January in Las Vegas, Nevada. CES—long known as the Consumer Electronics Show, and one of the world’s largest technology events—has in recent years included a growing energy technology component. Bob Mumgaard, co-founder and CEO of Commonwealth Fusion Systems, spoke at the conference as part of an opening keynote in a fireside chat with Siemens AG CEO Roland Busch.

Mumgaard in Las Vegas announced that CFS would collaborate with chipmaker NVIDIA and Siemens to develop a digital twin of its SPARC fusion machine. The companies said their work will apply artificial intelligence (AI), and data and project management tools, to accelerate commercial fusion. NVIDIA CEO Jensen Huang during his keynote reiterated that his company wants to be immersed in so-called “AI factories,” providing all manner of technology—blueprints, hardware, operating systems—to keep AI’s future on track. That would include supporting the energy needed to power AI.

“CFS will be able to compress years of manual experimentation into weeks of virtual optimization using the digital infrastructure developed by NVIDIA and Siemens,” said Mumgaard. “Through this collaboration, we’re demonstrating how AI and integrated digital engineering can accelerate progress from design to grid power. This will allow us to transform how we build and operate fusion machines in the race to commercial fusion.”

Mumgaard prior to the event said, “CES is where the future shows up first. Being here signals that fusion is entering the mainstream of technology. Fusion is about hope—building a future that promises energy abundance and that will one day power all of the innovations that CES showcases.”

Joe Paluska, the company’s chief marketing officer, said the company’s showcasing of its SPARC technology at CES marks a milestone. “We want everyone, not just physicists, to feel invited into the story of commercial fusion energy. That’s why we’re excited to have fusion where people who are thinking about the next big thing are,” said Paluska.

CFS already uses Siemens’ digital tools to improve the efficiency of its manufacturing processes and operations at the company’s magnet factory in Devens, Massachusetts. CFS in December 2025 completed and delivered its first superstrong magnet, which it said is the “culmination of years of work to develop and manufacture the foundational technology to bring fusion energy to the grid.”

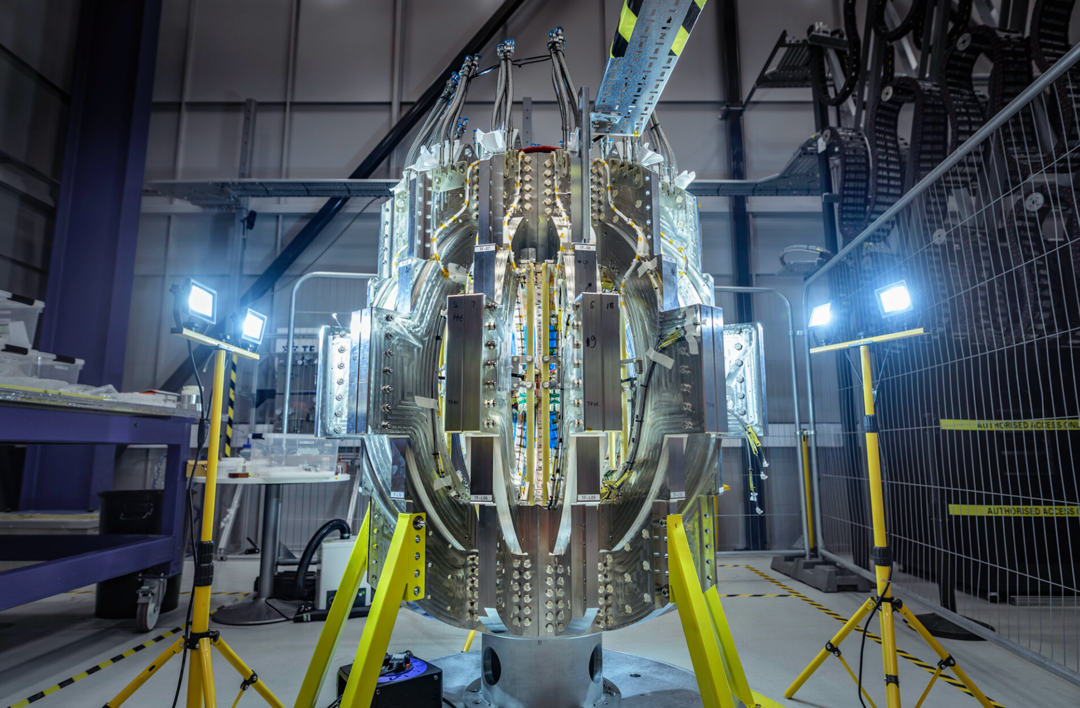

The 24-ton steel-clad magnet was moved across the CFS campus in Devens to the SPARC facility. It’s one of 18 D-shaped toroidal field (TF) magnets (Figure 2) needed for SPARC. Brandon Sorbom, the company’s chief science officer and co-founder, commented on the importance of the milestone in a company blog post, noting the progression from ideas to prototypes, and from initial manufacturing to full production.

“We didn’t just make a single magnet. We made a whole manufacturing facility that can make many, many magnets,” said Sorbom. “We learned how to set up a factory and run it at speed. Full steam ahead!”

SPARC and ARC feature three types of HTS magnets: toroidal field (TF), poloidal field (PF), and central solenoid (CS). The company builds its TF magnets with NINT technology (non-insulated, non-twisted construction) that houses many layers of HTS tape within a spiral groove in a flat steel plate. The company calls the plates pancakes, and a stack of 16 pancakes forms a single TF magnet. “Basically, NINT allows us to build stronger, smaller magnets faster,” Sorbom said, noting the NINT pathway is available because SPARC’s TF magnets run with a steady electrical current.

CFS wrote that “with steady current, we don’t need electrical insulation between the turns of a magnet. When the magnet is cooled down and then charged up, the electricity naturally flows along the superconducting pathway and ignores the surrounding metal with its relatively high resistance. It’s like the difference between skiing on fast snow instead of concrete.

“The ‘NT’ part of NINT refers to the superconducting tape being non-twisted. Again, the steady current makes this simpler approach possible: the TF magnets don’t require the helical twist that’s electromagnetically helpful for the superconducting cables in pulsed magnets.”

Mumgaard, in a video update on the project in early January, said, “The activity in Devens at the SPARC facility continues to be at an all-time high.” He continued, “This is the six months where the plant turns into an operation and the tokamak turns into what looks like a tokamak.”

Type One Energy and Tennessee Valley Authority

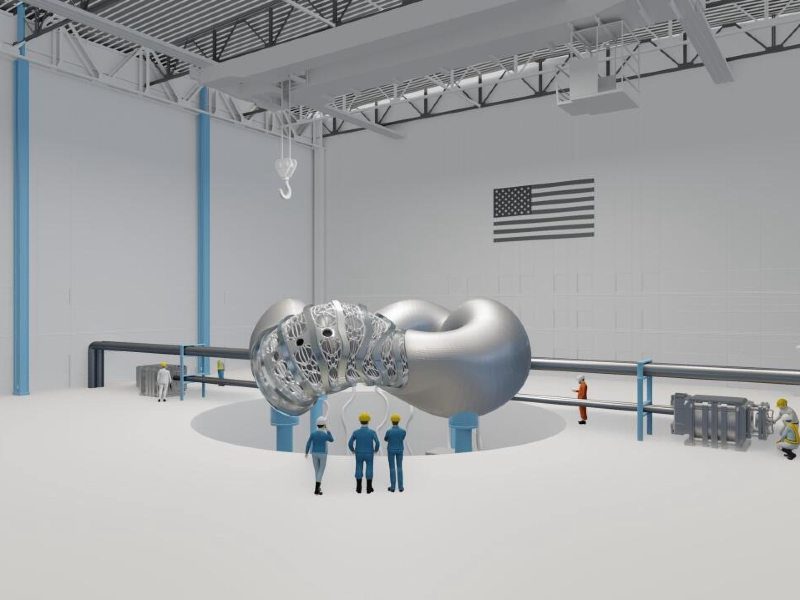

A retired coal-fired power plant site in Tennessee is now home to a collaborative effort to build a fusion power plant. Type One Energy, which began as a spinoff at the University of Wisconsin and is now headquartered in Knoxville, Tennessee, has partnered with major Southeast U.S. utility Tennessee Valley Authority (TVA) to build a prototype stellarator at TVA’s retired Bull Run fossil plant in Clinton, Tennessee.

Type One Energy last year announced completion of the first formal design review of Infinity Two, a 350-MW stellarator fusion pilot power plant. In addition to TVA, Oak Ridge National Laboratory also is involved in the project. Type One has said the stellarator “is the only fusion technology to have demonstrated stable, steady-state operation with high efficiency, characteristics which are important for TVA and others in the industry who need to reliably generate on-demand power at competitive prices.”

“TVA is a leader in pursuing advanced nuclear technologies we need to power America’s economic prosperity and fuel artificial intelligence, quantum computing, and advanced manufacturing,” said Don Moul, TVA president and CEO, last summer. “We are strategically partnering with innovative companies like Type One Energy to advance the development of nuclear technologies, and I am excited about the possibility of the first U.S. commercial stellarator fusion power plant being built in the Tennessee Valley.”

Type One’s team told POWER that as an original equipment manufacturer (OEM) and fusion technology provider to electric suppliers and utilities, the company can repurpose the infrastructure and the workforces at retired and aging fossil fuel power plants.

“We’re currently working with TVA to repurpose the infrastructure at their retired Bull Rull coal-fired power plant in the United States,” said Type One Energy CEO Chris Mowry. “It is a ready-made platform for hosting the future of energy: fusion. This repurposing of existing infrastructure is a strategy that fits well with the challenges and opportunities facing other energy markets around the world. According to the U.S. Energy Information Administration, the United States is home to 339 retired fossil power plants with 157 of them identified by the U.S. Department of Energy as candidates for repurposing. Each of these plants have significant infrastructure that can be repurposed to build safe, affordable fusion energy plants.”

The company said repurposing old fossil-fueled power plants could include not only their workers but also infrastructure such as land, water access, power grid access, and switching facilities.

“The very first employee that we hired at Bull Run was the plant manager of the old coal power plant that—when it was commissioned in the 1960s—was the largest, most efficient power generation device on earth,” said Mowry. “This is not just about a new technology, which is really important, but it’s also about the opportunity to repurpose talent and the workforces that already exist in communities. We always talk about repurposing infrastructure, but we can also repurpose talent. That’s a real value proposition to local communities.”

Type One Energy has said the Infinity Two architecture is grounded in stellarator fusion technology (Figure 3). The company said the “technology has, uniquely within the fusion industry, demonstrated stable, continuous steady-state operation at large scale by the W7-X machine. By properly architecting Infinity Two, Type One Energy is creating a proprietary fusion power plant design that supports a compelling two-year power plant operating cycle separated by 30-day planned maintenance outages using today’s existing materials and enabling technologies. The company also made use of its partner-rich commercialization program to access the power generation industry’s deep expertise in power plant engineering design. Among other firms, AtkinsRealis assisted in developing the design of those Infinity Two systems and structures not part of Type One Energy’s core focus on the stellarator fusion technology.”

The W7-X machine refers to Wendelstein 7-X, which is the world’s largest stellarator fusion device, located in Germany. Researchers have said the W7-X is designed to prove the feasibility of continuous operation for future fusion power plants, unlike pulsed reactors. The technology, according to developers with the Max Planck Institute for Plasma Physics in Germany, uses complex magnetic fields to confine superheated plasma. Testing of the device has shown promise toward the stellarator’s potential for steady-state energy generation.

Thea Energy

A Kearny, New Jersey–based company is building what it calls “a more economical and scalable version of a stellarator system architecture.” Thea Energy officials told POWER it has applied a phased array control system to fusion, which allows for simpler and less-expensive hardware, “and the ability to dynamically tune system performance in the software stack over an asset’s lifetime.”

Thea Energy was spun out of the Princeton Plasma Physics Laboratory (PPPL) and Princeton University; the Ivy League school is where the stellarator was originally invented. The company completed a $20 million Series A funding round in 2024, and was selected as one of eight inaugural awardees of the U.S. Department of Energy’s Milestone-Based Fusion Development Program. Thea Energy co-founder and CTO David Gates developed stellarator magnet array technology at PPPL as part of the ARPA-E BETHE (Advanced Research Projects Agency-Energy Breakthroughs Enabling THermonuclear-fusion Energy) program.

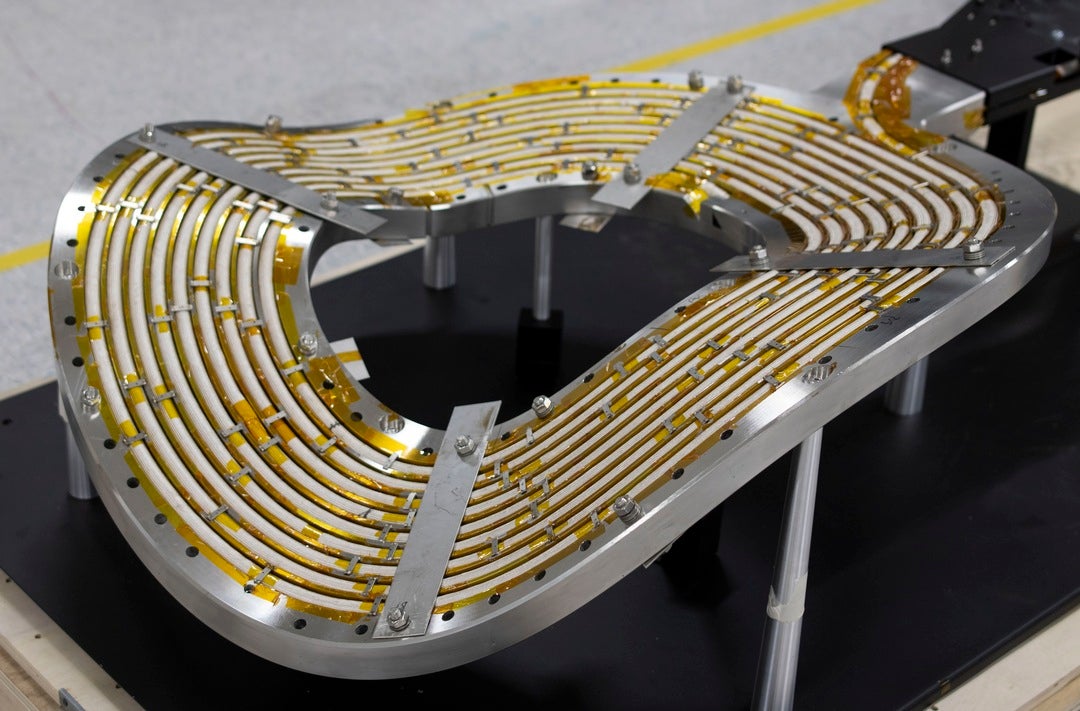

The company has said its “proprietary stellarator technology utilizes arrays of planar magnets (Figure 4), eliminating the prohibitively complex and expensive 3D magnetic field coils required in all other proposed stellarator architectures. Combined with the advent of modern high-temperature superconductors, our stellarator breakthroughs have changed the trajectory of fusion energy.”

Brian Berzin, co-founder and CEO of Thea Energy, told POWER: “Commercial fusion power will bend the trajectory of humanity sharply upward. Thea Energy is building a more practical, scalable, and economical fusion system based on the stellarator, one of the most scientifically mature fusion architectures. We have done this by leveraging a software-controlled array of simpler, mass-manufacturable superconducting magnets to replace the historically limiting 3-dimensional coils that were required by prior generations of stellarators.”

Berzin, who said Thea Energy has a team of more than 80 engineers, physicists, and commercialization experts based in Kearny, added his group is “really excited about our ability to commercialize a practical, cost-competitive fusion power plant—our architecture utilizes an array of about 300 wound magnets to eliminate the prior, major limitation of the stellarator: the 3-dimensional magnets that were wildly difficult and expensive to manufacture due to their complexity and precision requirements. Our proprietary architecture can individually control each planar magnet in the array using a software stack, while also tuning out manufacturing and assembly errors as well as system wear and tear over its operational lifetime. You can think of it as calibrating and playing a video on your computer screen.

“Our planar coil stellarator architecture can also uniquely leverage AI to increase real-time system performance and allow for long-term software level system updates, meaning for the first time, fusion systems are no longer limited by fixed hardware,” said Berzin. “We recently announced our Helios stellarator power plant architecture. The initial paper provides a comprehensive view of a fusion power plant that does not require any miracles to commercialize. Our Helios power plant (Figure 5) will unlock the deployment at scale of fusion energy, enabled by more traditional system manufacturing and construction, efficient maintenance, a high capacity factor, and competitive economics.

“Helios achieves several world firsts for fusion, including magnets adaptable to real-world conditions, an ‘X-point divertor’ capable of commercial operations [such as the exhaust system for a fusion power plant], and a sector-based maintenance scheme enabling high power plant uptime,” said Berzin. “Our breakthrough Helios design is now accelerating the formation of commercial partnerships and the first customers for Thea Energy fusion power plants.”

The company told POWER it is currently designing and considering siting locations for its first integrated fusion system, Eos, that will produce fusion neutrons at scale and in steady state. Site selection is scheduled for this year. The group said operation of Eos, planned by 2030, “will catalyze the subsequent deployment of fusion energy on the grid via the company’s Helios power plant.”

TAE Technologies

California-based TAE Technologies made a splash with its recent $6 billion merger with Trump Media & Technology Group (TMTG). The deal creates one of the first publicly traded fusion energy companies.

TAE said it wants to site and start construction of a 50-MW utility-scale fusion power plant this year, and also wants to build more stations in the 350- to 500-MW range. Officials have said the company has engaged in more than a quarter century of research and development to “significantly reduced fusion reactor size, cost and complexity.” It said it “has built and safely operated five fusion reactors.”

The new company’s co-CEO—former California congressman Devin Nunes, the CEO of TMTG—in early January said the group is accepting applications from state and local governments interested in being home to fusion reactors. Requirements to apply include a minimum of 20 acres to site multiple fusion reactors, along with access to a grid interconnection, and the ability to provide security. Nunes said a decision is expected within weeks, noting the company would like to begin construction this year.

Nunes, who has worked closely with President Donald Trump, also said to no surprise, “We’re only going to be building this in a red state,” which means left-leaning states including his own California need not apply. Nunes in a statement wrote, “The TMTG team is actively holding discussions with multiple states and entities about potential sites as we look forward to completing this merger. These are the initial steps to spark a renaissance in American energy to secure safe, clean, abundant, and affordable fusion power that will lower Americans’ energy bills and guarantee Americas predominant position in the AI revolution.”

TAE has said its “fusion machine design is compact and linear so a commercial fusion power plant would be readily scalable for mass manufacturing.” The company said it “is pursuing fusion with hydrogen-boron [also known as p-B11 or p11B] because it is abundant and non-radioactive, making it the most sustainable option for operating and maintaining commercial fusion power plants.” The company also said its technique to produce fusion power is called “advanced beam-driven Field-Reversed Configuration (FRC),” which it said “solves challenges to delivering scalable, sustainable commercial fusion power.”

Helion Energy

A group headquartered in Everett, Washington, is working toward a commercial fusion power plant in that state. Helion Energy is building its seventh-generation fusion prototype, with a goal of proving its technology can provide grid-scale power.

Construction of the company’s Orion fusion power plant in Malaga, Washington, began in July of last year. Tech giant Microsoft has signed on to start receiving power from the Orion facility as soon as 2028. POWER in 2023 covered Helion’s agreement with Nucor, the largest steel producer and recycler in North America, to develop a 500-MW fusion power plant at a Nucor steel manufacturing facility in the U.S.

Helion’s approach is to directly convert fusion energy into electricity, using deuterium-helium-3 (D-He3) fuel and a field-reversed configuration system for what it calls “potentially cheaper, smaller-scale fusion power.”

David Kirtley, the company’s co-founder and CEO, has said the group’s goal is more than just proving fusion energy is possible. Kirtley on the company’s website wrote: “We use a unique fusion fuel: deuterium-helium-3 (D-He-3). This sets us apart from most fusion approaches because it requires higher temperatures than more traditional fuels while relying on a fuel source that isn’t naturally abundant on Earth.

“Why did we choose this approach? Among other benefits, D-He-3 maximizes our ability to directly capture electricity, a large advantage when building a fusion system for commercial deployment,” wrote Kirtley, who added: “By focusing on D-He-3 fusion, we believe we are on a more efficient and cost-effective path to commercial fusion power. Our first-principles approach, assessing each fuel’s potential for commercialization, consistently pointed to D-He-3 as the fastest route to market-ready fusion energy. While there are intermediary challenges, overcoming them promises the most robust and economically viable solution for fusion power.”

The company last fall leased space near its Everett headquarters that will house an assembly line to build the capacitors needed to deliver power to its fusion generator, and then capture the energy produced. Melanie Nakagawa, Microsoft’s chief sustainability officer, at last July’s groundbreaking for Orion said, “While the path to commercial fusion is still unfolding, we’re proud to support Helion’s pioneering work here in Washington state as part of our broader commitment to investing in sustainable energy.”

Tokamak Energy

Tokamak Energy, headquartered in the UK, in December of last year said it set three performance records ahead of a major upgrade to its ST40 fusion energy machine. The company said it ended the year by achieving its highest plasma current, highest stored energy, and highest fusion triple product, which it said are “all key measures on the path to delivering clean, limitless fusion energy.”

The December announcement came on the heels of a November 2025 report that the group had recorded breakthrough results for its strategy to replicate fusion power plant fields for the first time with its magnet system. The company said its Demo4 (Figure 6) “also demonstrates the transformative potential of high-temperature superconducting (HTS) technology across a range of spin-out applications, from power distribution for data centers, electric motors for zero emission flight, and fast, efficient magnetic levitation transport systems.”

Tokomak Energy said the compact spherical tokamak at the company’s Oxfordshire headquarters is now preparing for a major upgrade for a new campaign of what it called “groundbreaking experiments in partnership with the U.S. Department of Energy (DOE) and the UK Department for Energy Security and Net Zero (DESNZ).”

“These superb results are a great way to finish the year and demonstrate how the ST40 team continues to push the limits, improving the already impressive performance of our compact high-field device,” said Otto Asunta, the company’s experiments chief for ST40, in a news release. “Breaking into the mega-amp range with our plasma current is a major milestone as we continue to build our knowledge of what will be needed for delivering fusion energy to future grids. We now look forward to working with the U.S. and UK governments on a new wave of experiments to deliver more cutting-edge science with our industry-leading device that has always punched above its weight.”

The company said the ST40 set a record by reaching 1 MA (1,000,000 amperes) of plasma current, surpassing its previous best of 0.85 MA, while stored energy was nearly doubled compared to previous campaigns. The group said, “This demonstrates that a plasma volume of just one cubic meter can hold immense power—an important insight on the path to energy-producing devices.”

Tokamak Energy noted, “Plasma current—the electric current flowing through the plasma inside a tokamak—is crucial for confinement. It generates a poloidal magnetic field that, together with the magnetic fields from coils, keeps the plasma confined and away from material surfaces inside a tokamak. In future devices, a high plasma current is required to also trap the fusion-born alpha particles. The fusion triple product, a measure combining plasma temperature, density, and energy confinement, is a key indicator of plasma performance.”

The company also said that its “latest campaign also saw the implementation of a new software called RT-GSFit that can reconstruct the plasma shape during a pulse at a millisecond time resolution (a thousand times per second). Integrating RT-GSFit into the ST40 Plasma Control System allowed the team to control plasma shape in real-time.”

The company said the ST40 “has now paused operations for the $52-million upgrade program, known as LEAPS (Lithium Evaporations to Advance PFCs in ST40), in partnership with DOE and DESNZ. The program will apply lithium coatings to all plasma-facing components (PFCs) using a lithium evaporation technique, building on pioneering work by Princeton Plasma Physics Laboratory and others that has shown lithium PFCs can significantly improve plasma performance.” The ultimate goal is to enable fusion conditions with good confinement that is compatible with sustainment for long durations in a future fusion pilot plant.

The company also provided an update on its Demo4, a complete set of HTS magnets built in a tokamak configuration, noting it has produced “milestone results at the company’s headquarters outside Oxford, achieving field strengths of 11.8 Tesla at –243C in recent tests. The world-first system had an incredible seven million ampere turns of electrical current running through its centre column, demonstrating huge potential for power distribution as HTS can deliver around 200 times the current density of copper.”

Warrick Matthews, Tokamak Energy CEO, said: “These results are a major victory for the race to deliver fusion and HTS as a disruptive new commercial technology. Demo4 represents over a decade of HTS innovation at Tokamak Energy. Born from our fusion mission, it validates one of the technical solutions for getting clean, limitless, safe, and secure fusion energy on the grid.

“Demo4 is also best in class at showcasing and demonstrating the transformative potential for superconductors, including power distribution for high-demand environments like data centers and applications across science, power systems, propulsion, and beyond,” said Matthews.

The ITER Project

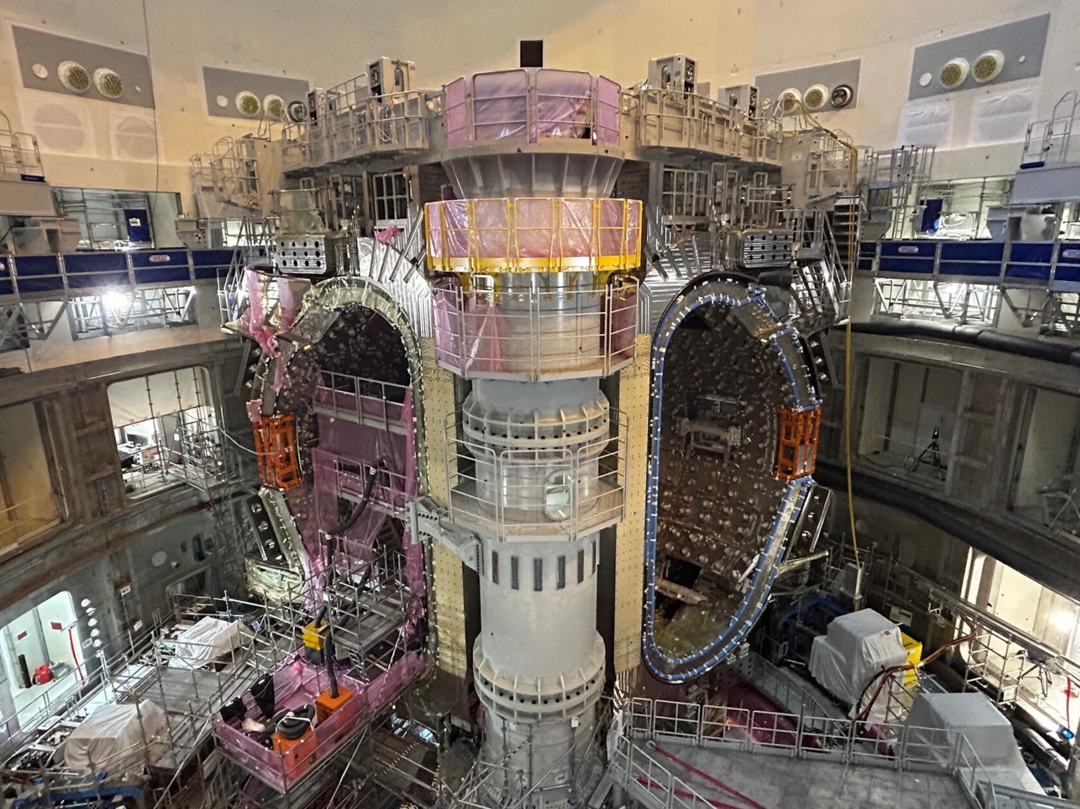

Construction continues on the ITER (International Thermonuclear Experimental Reactor) project in Saint-Paul-lez-Durance, in the south of France, an experiment in fusion that was launched in 1985. The ITER facility is designed to demonstrate the scientific and technological feasibility of fusion power, and would be the world’s largest experimental fusion facility. ITER is a global collaboration of nearly three dozen nations, that as of January includes the 27 member countries of the European Union, in addition to China, India, Japan, South Korea, the Russian Federation, and the U.S.

Switzerland is also a participant after renewing its association on January 1 of this year. The UK, following Brexit and its subsequent withdrawal from Euratom, is no longer participating, though ITER for now is honoring existing contracts with UK companies and research institutes that have been involved with the project.

Officials with the ITER project (Figure 7) have said its primary objective is the investigation and demonstration of burning plasmas. Those are plasmas “in which the energy of the helium nuclei produced by the fusion reactions is enough to maintain the temperature of the plasma, thereby reducing or eliminating the need for external heating. ITER will also test the availability and integration of technologies essential for a fusion reactor [such as superconducting magnets, remote maintenance, and systems to exhaust power from the plasma] and the validity of tritium breeding module concepts that would lead in a future reactor to tritium self-sufficiency.”

Greg Demchak, vice president, Emerging Technologies with Pennsylvania-based Bentley Systems, told POWER, “Bentley Systems role in the ITER project is to provide advanced 4D visualization tools with comprehensive tracking and planning capabilities along with digital twin technology. The Bentley SYNCHRO software is essential for planning and executing the complex construction and assembly process of the fusion reactor. This technology allows engineers to create a ‘living, breathing replica of the physical project’ that is updated in real-time, which, when combined with 4D planning, enables them to visualize the construction process step-by-step.”

Demchak added, “To support projects like ITER and others requiring advanced visualization, Bentley has continued to enhance its 4D visualization capabilities. These improvements include leveraging technology from Cesium, a leading 3D geospatial company acquired by Bentley, to deliver more interactive and navigable virtual models. This enables teams to identify potential issues, refine installation sequences, and maintain alignment across all teams and stakeholders.”

The ITER team in a recent update said another penetration benchmark was reached in December with the infilling of 15 busbar openings on the L3 and L4 levels of the Tokamak Building. According to an ITER news release, “The infilling team spent months qualifying a bright blue elastomer produced by the Norwegian company Elkem to ensure it met the required fire segregation, radiation shielding, leak-tightness confinement function, and other standards. Among other assessments, the fire qualification tests included heating the elastomer to 1,100C in a specialized furnace and ensuring it did not permit a heat transfer in excess of 120C on the other side of the opening. By undertaking this qualification process, which was done in partnership with the Efectis laboratory in France, the teams ensured that future fusion construction projects can use this elastomer product from day one if they have matching safety requirements. The elastomer is readied by mixing two different liquids and then pressurizing it to remove the gas bubbles.”

“This was the first time this type of infilling had been done at ITER, so we had a very complex problem and, together, we found a simple solution,” said Jose Manuel Sanchez Cuevas, the mechanical and piping supervisor. Cuevas was the contract responsible officer for the busbar infillings. Officials said there are thousands of small penetrations, or openings, in the Tokamak Complex to allow pipes, cables, and components to pass through walls and slabs. Those spots “need to be infilled using different solutions that meet the same safety and nuclear safety standards as the surrounding wall material.”

The ITER Council at its 37th meeting, held in November 2025, said the project is ahead of schedule, and in a report wrote that it “welcomed the steady progress on assembly and installation of the sector modules.” The Council also noted “progress on assembly of the central solenoid, start of production of all divertor components, installation of the first gyrotron for electron cyclotron heating, completion of the bioshield penetrations in the Tokamak Building, and sustained positive interaction with the French nuclear safety regulator.”

—Darrell Proctor is a senior editor for POWER.