POWER

-

Coal

Preparation keyed Entergy’s responses to Katrina, Rita

With the 2006 hurricane season about to begin, climatologists are predicting that the Atlantic Ocean will spawn 17 “named” storms this summer and fall, with 9 categorized as hurricanes and 5 expected to be “intense.” Whether or not your plant lies in a vulnerable coastal area, you’d do well to learn a few lessons from Entergy’s unique experience last year.

-

Coal

Curbing the blue plume: SO3 formation and mitigation

Understanding why stack emissions become opaque leads to better choices of systems for controlling SO3 and other pollutants, based on current and future plant operating configurations.

-

Coal

How accurate primary airflow measurements improve plant performance

Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that underestimate primary airflow levels can lead to negative operational outcomes that include increased boiler gas temperatures, flyash loss-on-ignition, excessive NOx emissions, and higher-than-necessary fan power consumption. We remind you how to avoid those headaches.

-

Business

Balancing people, plants, and practices

An essential ingredient in the success of any business endeavor is thorough planning. We’ve all heard the axiom "proper prior planning prevents poor performance" or a variation on that theme. Why the need for peak performance? Competition within the industry has never been as intense, with utilities combining in search of economies of scale. The […]

-

Instrumentation & Controls

Steam turbine upgrading: Low-hanging fruit

In 1500, Leonardo Da Vinci drew sketches of a device that rotated when hot air going up a chimney passed through a set of fan-like blades. Leonardo called his invention a "chimney jack," and although it only turned a roasting skewer, it gave birth to the idea of mounting blades on a shaft to convert […]

-

O&M

Keeping condensers clean

There’s a relatively easy way to make a steam plant more efficient and reliable: keep the tubes of its condenser(s) clean. According to George Saxon, Jr., VP of international sales and marketing for Conco Systems Inc. (Verona, Pa.)—a company whose specialty is cleaning and maintaining condenser tubes—"There are two major problems that result from dirty […]

-

Instrumentation & Controls

A permanent solution to generator vibration problems

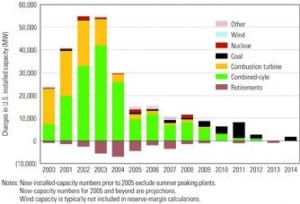

Remember the slogan, "Never trust anyone over thirty?" Chances are you’ve joined the ranks of the over-thirty generation and are dealing with your own personal "maintenance" issues—not unlike the fleet of generators at larger U.S. power plants, whose average age is about 30. Given the continuing growth in U.S. electricity demand and the cost and […]

-

Instrumentation & Controls

Brain surgery breathes new life into aging plants

Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager number of students pursuing engineering degrees, and the accelerated retirement of the older workers who make up the industry’s experience base. On top of this, […]

-

Instrumentation & Controls

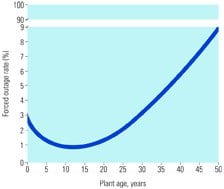

Designing steam cycles to avoid corrosion

U.S. power producers and owners of industrial steam systems each spend about $15.4 billion annually to combat corrosion in their plants. Scale and deposits are thought to be responsible for another $20 billion a year in reduced plant efficiency and lost generation capacity. Corrosion is the primary cause of every other forced outage, and the […]

-

Western coal rush

—Dr. Robert Peltier, PE Editor-in-Chief The hot hand in coal-fired power plant development is undoubtedly held by Nevada. In a departure from Sin City’s latest marketing slogan, "What happens in Vegas, stays in Vegas," most of the 5,500 MW to be generated by plants proposed for the state is destined for use elsewhere, principally […]