Huawei Unveils Intelligent Substation Solution at the CEPSI Conference

To sustainably support the needs of growing populations while providing the power demanded by AI applications, the electric grid must be digitized. Standing in the way of this vision are the many hundreds of thousands of substations around the world that continue to operate on aging analog systems or have only basic digital capabilities. These traditional substations rely heavily on manual operations. They have passive monitoring systems that fail to detect complex risks. Equipment status checks remain fragmented, with inefficient manual inspections regularly missing defects and operational vulnerabilities.

Their primary function, of course, is to manage the flow of electricity by adjusting voltage to make it safe and usable. High-voltage electricity from transmission lines is stepped down by transformers within a substation before being distributed to homes and businesses. But substations have other functions such as protection from grid faults. In fact, they typically have more than 20 systems operating independently.

Unfortunately, these systems usually operate on a diverse range of data models that lack consistent standards. While a great deal of data is collected, the presence of countless information siloes means the data cannot be deeply mined, analyzed, and utilized. Utilities and grid operators are unable to use their data to streamline management and monitor equipment condition effectively. Beyond data integration, vital activities such as collaborative analysis, maintenance, and cybersecurity have become increasingly challenging due to the outdated nature of substation technology.

For example, the time it takes to deploy substation systems is lengthy. Installation and debugging of cameras is labor-intensive. Maintenance personnel must go through a checklist of thousands of inspection points and record readings from hundreds of analog meters within the substation. The inspection of one substation can take up to six hours. With daily inspections recommended, such a time factor is untenable.

All of this makes it extremely difficult to manage existing grid operations and almost impossible to upgrade the grid by adding the next-generation features that support AI and the needs of a modern society.

The Huawei AI-Based Intelligent Substation Solution

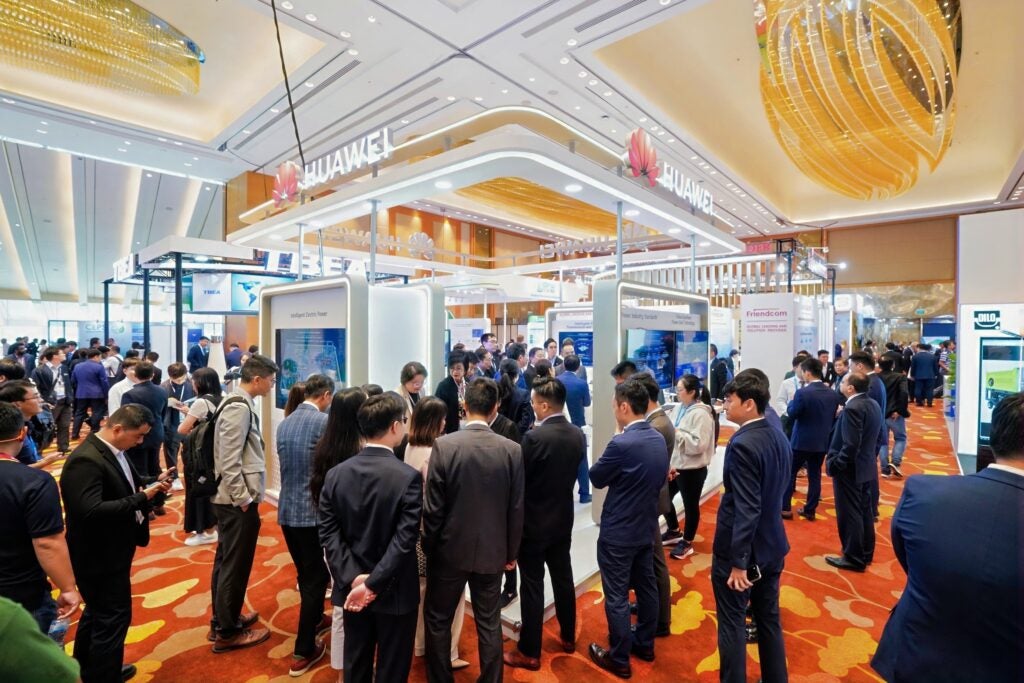

Hence, Huawei chose the 25th Conference of Electric Power Supply Industry (CEPSI 2025) in Singapore in late October of 2025 to unveil its AI-based Intelligent Substation Solution. In collaboration with industry partners, Huawei has developed a host of new features and AI capabilities for end-to-end substation intelligence.

The entire station is connected through a unified Internet of Things (IoT) network, with cameras automatically going online at preset positions. These features greatly accelerate the deployment and functionality of digitalized grid services:

- Inspection videos from robots and drones are transmitted in real-time.

- Multi-dimensional AI models mine and comprehensively analyze all operations and maintenance data to provide proactive warnings and ensure all necessary maintenance actions are up to date.

- A fiber optics network and an intelligent sensing algorithm engine open the door to rapid detection of tiny changes in vibration waveforms. This information is aligned with Huawei AI large language models (LLM) and optical-video linkage to precisely identify personnel or foreign object intrusion events. Using the management system to coordinate perimeter sensing terminals, on-site verification is performed for secondary confirmation by operations staff. This fiber-visual integration approach achieves extremely low false alarm rates and improves detection rates.

This AI-based intelligent fiber-optic sensing solution enhances perimeter protection and underground cable security for substations and power plants through high precision, environmental resilience, and 24/7 perception. This has significantly improved safety while reducing manual inspection costs and boosting operational efficiency.

Automation of Inspections

There will always be the need for inspections by humans. However, the integration of sensing devices with AI algorithms within the Huawei Intelligent Substation Solution automates a great many routine inspection and data collection actions. In the real world, manual inspection time is cut by at least 40%.

End-to-end connectivity of devices and substation systems facilitates in-depth analysis of components and systems within the substation, the substation as a whole, or a network of substations. The system can intelligently diagnose the health status of equipment and individual components, doubling the detection rate of potential faults. This transforms maintenance and repairs from their traditional reactive approach to being able to provide proactive warnings, recommendations, and automated actions with accuracy.

Additionally, the Huawei Intelligent Substation Solution deeply integrates on-site operational controls with smart mobile terminals to enable operators to digitally supervise and guide key operational processes. This capability has been found to reduce on-site operational errors and policy violations by 85% while shortening personnel training time by 30%.

The Intelligent Power Plant

The Intelligent Substation Solution is one aspect of a larger intelligent power plant vision. The intelligent power plant can be characterized by hierarchical collaboration, data-driven operations, and closed-loop business processes. Leveraging Huawei’s advanced information and communications technology (ICT) infrastructure in networking, computing, and storage, it becomes possible to integrate IoT, big data, AI, 5G, automation, and digital twins to span the entire chain of power plant, substation, and grid operations.

The Huawei architecture is built on four layers:

- The terminal sensing layer serves as the “nerve ends” of an intelligent power plant and gathers data about the local environment from videos, as well as accumulating data on equipment status, and numerous other instrument parameters.

- The network transmission layer is the artery system for information to flow reliably and securely across the intelligent power plant while operating at high-speed and low latency.

- The platform hub layer is the brain of the intelligent power plant, responsible for integrating data across the entire facility via data storage, computational analysis, AI modeling, and digital twins.

- The application service layer acts as the business implementation carrier for the intelligent power plant. It can create scenario-based applications tailored to full lifecycle management of a power plant (construction, operation, maintenance, safety, business operations, and environmental protection).

“Computing power is the foundation of AI, electricity is the ceiling of computing power and AI is the future of electricity,”,” said Jacky Wang, Vice President of Electric Power Digitalization Business Unit at Huawei. “For the energy industry, real-time and high-quality data are essential to get the most out of AI, while highly reliable communication networks are the foundation for real-time, high-quality data. We need to redefine digital scenarios and the communication target network, as well as reposition network security.”

During the CEPSI Conference, Huawei hosted the IDS Club roundtable and the APAC Energy Power Partner Forum, engaging both customers and partners on regional development and opportunities. Energy companies also visited Huawei OpenLab to explore its intelligent power solutions.

For more information on CEPSI please visit: https://e.huawei.com/sg/events/apac/cepsi-2025