Courtesy: International Climbing Machines

Drones and robots are everywhere these days, but using them effectively for power plant operations and maintenance (O&M) without breaking the bank is neither simple nor straightforward. Navigating the technological and regulatory issues requires a keen focus on what you need to do and then matching capabilities closely with your requirements.

If you’re still thinking of drones and robots as more toy than tool, think again. The drones now working in the power sector have gone far beyond remote-control hobbies and now resemble something closer to their autonomous military brethren. In February, Xcel Energy became the first U.S. utility to be licensed by the Federal Aviation Administration (FAA) to operate its drones in beyond-visual-range inspection deployments. For a company that has more than 7,000 miles of transmission lines, many traversing remote environmentally sensitive areas, the ability to send drones out on their own in pre-programmed flight paths is a game-changer.

Previously, the utility had to use helicopters, which are very expensive to operate, disruptive in many areas, and carry risks for employees on inspections. While the drones used are not cheap—prices for those capable of such missions run into the tens of thousands of dollars—they represent enormous savings over the alternative.

“[U]nmanned aircraft systems are a great example of boosting our productivity through technology,” Teresa Mogensen, Xcel Energy’s senior vice president for transmission, said at the time. “Employees will also use drones to observe environmentally sensitive areas without the use of trucks, helicopters or other utility equipment, minimizing the environmental impact.”

The drone model Xcel is using, the Pulse Aerospace Vapor 55, was supplied by Lafayette, Colo.–based FLoT Systems and in fact resembles a small helicopter (Figure 1). The four-and-a-half-foot-long drone weighs about 30 pounds (depending on its job) and has a flight time of around an hour, operating in a 5-mile radius from the drone pilot and at altitudes up to 10,000 feet (though as discussed below, regulations in the U.S. restrict operation to under 400 feet). It can mount both video cameras and lidar inspection systems.

Know the Law

But putting a tool like the Vapor 55 to work for your plant or utility is not a matter of sending a few guys down to the local hobby store to pick one up.

“What a lot of people don’t realize,” Brett Velicovich, CEO of Expert Drones/Dronepire told POWER in a February interview, “is that when you are operating drones for business purposes, you are required to get an exemption from the FAA that says you can legally fly your drone over this particular area at this particular time.”

The laws governing commercial use of drones and other unmanned aircraft systems (UASs) are unsettled and currently in flux, but for now, the FAA takes the position that it is entitled to regulate their operations because they are “aircraft” under existing law. That means that to avoid possible legal trouble, plant operators need to follow FAA regulations.

Fortunately, FAA oversight is not terribly burdensome. Commercial drone operators need to apply for an exemption under Section 333 of the FAA Modernization and Reform Act of 2012. (That section, in fact, only directs the FAA to assess the need for regulating UASs and develop appropriate regulations. The FAA has issued an array of rules in addition to a proposed framework that would allow commercial use without prior authorization under certain circumstances.) The process of obtaining a Section 333 waiver and a Certificate of Waiver or Authorization (COA) requires the assistance of a lawyer and can take several months.

A Section 333 waiver, despite what might be assumed from the name, does not exempt the UAS operator from federal regulations. Rather, it allows daytime UAS use under 400 feet in specific areas (usage at night is prohibited).

There are also an increasing number of state and local regulations governing the use of drones—the types that are allowed and how and where they may be operated. For this reason, generators considering the use of drones in plant operations and maintenance (O&M) are strongly advised to consult a lawyer familiar with drone law before their first flight. Failure to do so could result in fines and potentially even criminal prosecution.

Getting Up to Speed

With an FAA exemption in hand and other legal restrictions dealt with, plant managers need to spend some time thinking about how a drone will be used and how it can save time and money and reduce risk to plant staff. “For that environment,” Velicovich said, “the local hobby shop is not going to be able to tell you what you need.”

Jon Amdur, vice president and program manager for unmanned aerial systems with Aecom’s design and consulting services division, told POWER that a lot of clients approach the use of drones without having a clear idea of what they can do and how they can help around a plant. “Sometimes the expectations are too high, and sometimes they are too low. They do not really understand what the systems are capable of.” Additionally, he said, the technology is advancing so rapidly that what can be done today may be significantly less than what is possible a few months later.

That’s why many generators and utilities employing drones do what Xcel did and engage the services of a third-party company that is familiar with the many varieties of commercial drones on the market and their various capabilities. Such firms can perform the inspections themselves or train plant staff to operate the generator’s drone fleet. The latter is less challenging than it might seem.

“There is a lot of misconception in the business world that drones are difficult,” Velicovich said, “because everyone seems to have flown or seen flown one of those little quadcopters that lifts off and immediately crashes into a wall and breaks. That’s not how drones work nowadays. It’s incredibly easy to fly these things now in a professional way.”

Modern commercial drones, Velicovich explained, have stabilizing technology that allows them to hover safely even when an operator is not at the controls. They also have “return home” functions that can bring them back to their starting point with the push of a button. Commercial drones also have GPS controls that allow them to follow precise flight plans as well as automatically stay out of restricted airspace or areas of the plant where it might be unsafe for the drone to go.

The latter function, known as “geo-fencing,” uses GPS to restrict where a drone will fly. When the drone reaches the edge of a restricted area, it will stop in midair even if the operator tries to make it go further. If the drone is taken into a restricted area, such as the vicinity of an airport, it will not even take off.

Putting Drones to Work

What can you do around your plant with the right drone? Possibly a lot more than you realize.

Drones have been available for power plant inspections for a few years (see “Drones Promise Faster, Easier Inspection of Boilers, Stacks, Towers, and More” in the April 2014 issue), but their capabilities are rapidly growing. In addition to video cameras (available in resolutions up to 4K), drones can also mount lidar, infrared (IR), multispectral and hyperspectral imagers, and essentially any inspection tool that is light enough for the drone to carry.

Drones are especially well suited for aerial mapping and 3-D modeling because of their ability to follow precise, GPS-guided flight paths. “You can literally create a 3-D model within minutes of a drone flying around your plant,” Velicovich explained. “You can completely map your entire infrastructure and create a digital model of your plant.”

(Note that while this sort semi-autonomous operation is allowed, the operator must still be at the controls and remain in visual line-of-sight at all times. Fully autonomous operation is not currently permitted by the FAA.)

Such aerial surveying and mapping is rapidly becoming a popular use for drones in the power sector, one that is drawing in companies not previously operating drones. UK Aerial mapping company Bluesky announced in January that it is partnering with drone airborne inspection and surveying firm Cyberhawk to provide a range of aerial survey and mapping services using UASs. The partnership will allow Cyberhawk, which provides inspection services for power sector facilities, among other clients, to offer larger, more sophisticated methods of data collection.

Drones offer particular benefits to renewable generators, as they can dramatically speed up inspections of wind turbine blades and solar photovoltaic (PV) panels. (For more on using drones for PV plant inspection, see “Solar PV O&M Best Practices in a Rapidly Changing Market” in this issue.) Fiberglass turbine blades need to be regularly inspected for cracking, but simple methods such as binoculars are inefficient, while more intensive methods such as climbing the turbine or using helicopters and cranes can be risky and cost-prohibitive. A drone, by contrast, can rapidly inspect blades with close-up, high-resolution video at far less cost than a helicopter. (For an example of such an inspection, see the video below.) While drones cannot completely replace other methods, they can help ensure more expensive approaches are used only where necessary.

Solar PV plants also need regular inspections for panel damage, cleanliness, and proper operation, but particularly with megawatt-scale systems, manual inspections are slow, inefficient, and costly. The use of thermal imaging has shown great promise in rapidly identifying failures (malfunctioning cells and panels typically show up as zones of differing temperature from their neighbors), but labor costs for panel-by-panel inspections and equipment costs for aerial surveys with manned aircraft are expensive enough that few plant owners use them very often.

Drone-mounted thermal imaging, however, can be fast, efficient, and cost-effective. The Electric Power Research Institute (EPRI) published a report in August 2015 assessing the possibilities for UASs in solar PV plant O&M, and concluded that, “Although it is unlikely that UAS can be used to perform corrective maintenance tasks (i.e., physical repairs), they are well positioned to speed up preventative maintenance practices. For example, UAS can provide comprehensive IR scans of an entire plant’s modules at a fraction of the cost and time” of manual inspections. “This means that potential performance issues can be identified plant-wide immediately and accurately without the use of statistical extrapolation,” the report notes.

Drone Support

Solutions for managing all that data are growing as well. Drone firm Sentera in October launched a software platform called OnTop that automatically tags and records location and other metadata for inspection photos, creating a customized, searchable map of the inspection and all photos associated with each inspected asset.

The future legality of completely autonomous drones is uncertain, but the drone industry is not waiting. One possible view of the future can be seen in the Dronebox, a product introduced by Singapore-based H3 Dynamics in February (Figure 2). The Dronebox is a drone base station that allows pre-positioning of autonomous drones, providing environmental protection, charging via solar PV panels and backup fuel cells, and remote networking. Using the Dronebox, a fleet of drones can perform regular programmed inspections or be triggered into action by specified events (a video of the Dronebox in action can be viewed at: http://bit.ly/1TBWDLO).

Though the market is new and it’s not clear how many generators are using drones in their O&M, the field is clearly growing. Navigant Research estimated in a September 2015 report that global revenue for drones and robotics technologies used in the transmission and distribution sector would grow from $131.7 million in 2015 to $4.1 billion by 2024. Meanwhile, revenue from use of UASs for wind turbine inspections is expected to top $6 billion over the same period. Xcel is far from the only U.S. utility pushing forward with drones—others such as Duke Energy are looking at how drones can cut O&M costs and streamline operations.

If you’re looking to learn more about drones and how to best use them around your plant, POWER is presenting a special workshop on drones at this year’s ELECTRIC POWER Conference & Exhibition in New Orleans April 18–21 (see sidebar).

|

Drone University at ELECTRIC POWER 2016 If you’re interested in learning more about using drones and robots in and around your plant, you won’t want to miss a special workshop at the ELECTRIC POWER Conference & Exhibition April 18–21, 2016, at the Morial Convention Center in New Orleans, La. During the workshop, Drone University: Utilizing Drones in Your Power Plant, drone experts will show attendees how drones can help assess safety conditions at plant sites, inspect equipment deep inside hard-to-reach areas, evaluate temperature distribution through aerial thermal imaging cameras, and more. Attendees will experience hands-on flight instruction and hear about future technologies that will offer substantial value to power plant professionals, as well as technical and regulatory requirements to safely integrate drones into operations. |

These Are the Robots You’re Looking For

What if you need to employ testing units or other equipment that is too heavy, bulky, or otherwise unsuitable for a drone to carry? Robotic inspection systems are the answer, and options are growing rapidly here as well.

Nuclear power plants have long been a growth area for robotics because of the number of areas in a plant where it may be unsafe for inspection personnel to go without cumbersome protective gear, or that cannot be manually inspected without time-consuming preparations such as draining storage tanks. One solution for the latter problem is the Inspector robot by Newton Research Labs and IHI Southwest Technologies, which can conduct semi-autonomous nondestructive examination (NDE) of storage tanks without requiring them to be drained or taken out of service, and at far less risk to plant staff than using divers (see “Robotic Inspections of Nuclear Power Plant Storage Tanks” in the February 2015 issue).

Robots have been used for inspections of the damaged reactors at Fukushima Daiichi in Japan, where continuing high levels of radiation (>5 Sv/hr) make direct inspections impossible. In that case, the 510 Packbot by iRobot (the same company that makes the Roomba robotic vacuum cleaner) was used to conduct assessments of damage to the reactors.

AREVA released its latest generation of nuclear plant robots last year, what it calls RIANA (Robot for Investigations and Assessments of Nuclear Areas, Figure 3). According to the company, RIANA is a motorized platform with interchangeable measurement or sampling modules that can be adapted to the needs of the job. It’s available with four-wheel or caterpillar track drive and is equipped with 3-D and thermal cameras as well as on-board lidar to navigate around obstacles and position itself precisely within confined spaces. The first RIANA was delivered to the French Atomic Energy Commission last June.

Robotic inspection systems are becoming more specialized and tailored for power plant needs. One growth area is boiler tube inspections. As anyone who has ever worked in a thermal plant knows, tube inspections are a difficult, dangerous, and unpleasant—but critical—element of power plant O&M. Tube wall failures are a common cause of forced outages, which means accurately predicting and preventing them is an excellent way of keeping revenue up and unnecessary costs down.

Performing NDE of boiler tubes by hand is slow and difficult enough to make it a major undertaking that requires several days of work, not just for the inspection itself but also for the time to set up and take down the necessary scaffolding. Robots are coming on the market, however, that can conduct precise automatic inspections in a fraction of the time, and without requiring extensive support equipment.

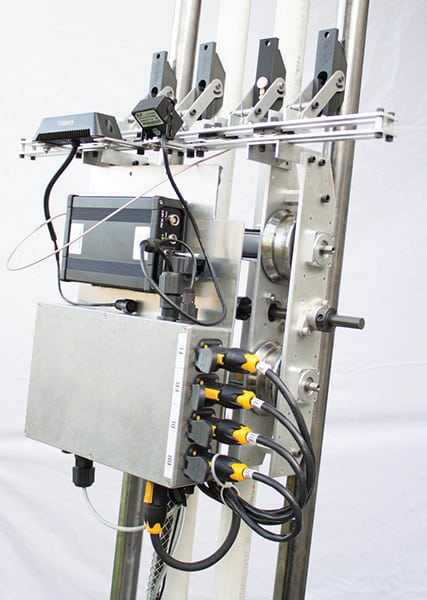

Gecko Robotics has introduced a robotic tube inspection system that can conduct ultrasonic and visual testing of boiler tube walls in less time than would be required without robotic assistance (Figure 4). Jake Loosarian, Gecko’s CEO, spoke to POWER about it in February. “Using the climbing robot, you can get your results about seven times faster than with previous methods. We can identify any problems for the plant manager, and they can then decide where they need to do repairs instead of taking a lot of time to locate the trouble spots.”

Because the system is automated, it’s capable of more precise and accurate inspection results than handheld scanners. Measurements are collected at different angles by an array of eight ultrasonic sensors.

Climbing High

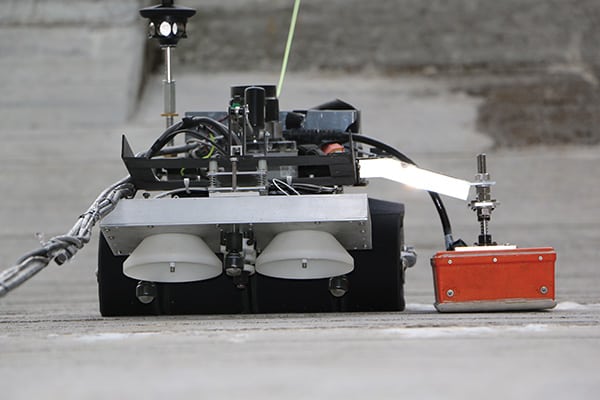

Climbing robots are among the options with the most potential for plant use because of their ability to remove the need for staff to ascend to potentially dangerous heights. Ithaca, N.Y.–based International Climbing Machines (ICM) has worked with EPRI to adapt its climbing robots to conduct NDE of very large concrete structures like dams and nuclear plant containment buildings—shown in the header photo (a video of the project can be viewed below). Using lidar positioning, highly accurate maps of the inspection data can be created. The ICM climbing robot can ascend a variety of surfaces and remains attached through vacuum suction. ICM’s robots have also been used for inspections of wind turbines (see the cover of this issue), as well as for maintenance tasks such as spraying coatings and sandblasting.

According to ICM President Sam Maggio, the robot is capable of climbing any surface on which it can maintain a vacuum seal, unlike robots that rely on magnets and that can only climb ferromagnetic materials. “It’s the vacuum chamber, which is surrounded by a rolling, very flexible seal, that allows it to go over very rough surfaces as well as surface obstacles,” Maggio said. Because the seal rolls over the surface rather than being dragged, the robot will not damage the surfaces it climbs.

Going Deep

Robots have been used for internal inspections of large pipelines for years, but the solutions are growing small enough to allow inspections of piping as narrow as 6 inches. GE Hitachi Nuclear Energy (GEH) recently introduced what it calls the Surveyor, a self-propelled, articulated robot that can inspect filled, partially filled, and dry piping from 6 inches to 48 inches in diameter (Figure 5). The robot can negotiate elbows and travel up to 1,000 feet from its entry point.

GEH personnel tested the Surveyor at the South Texas Project nuclear plant in December 2014, and the robot was able to inspect a length of buried pipe without requiring modifications to the piping system. An earlier version of robot has been used for inspections of buried piping in the oil and gas sector, but this was the first time it was used at a nuclear plant.

According to the spokesman Jonathan Allen, GEH is in discussions with several customers about the Surveyor and is planning for a deployment at a U.S. nuclear power plant this spring.

Looking Ahead

Tim Saffold, Aecom’s executive vice president of joint unmanned systems and training solutions, suggested that the drone industry is poised for some dramatic gains in productivity once the FAA settles on a clear regulatory scheme for autonomous, beyond-line-of-sight operation. “When we have the proper procedures in place,” he said, “it’s going to open up a lot of opportunity. It’s going to increase the efficiency by an order of magnitude, and when you do that, you increase the opportunity to provide more data, and thus drive down the costs of the service.”

If you’re enthusiastic about the possibilities of UASs and robots, you may be wondering how soon they’ll be able to go beyond inspections to performing actual maintenance. Robotic maintenance is still in the early stages—robots designed by Toshiba are being proposed for repairs at Fukushima in the next few years—but as far as UASs, Aecom’s Amdur suggested that’s still a ways off. “I think given the level of accuracy and detail that is required for that, I don’t think it is going to happen any time soon.”

Still, it’s coming at some point. Velicovich said, “We get requests all the time” from clients who have thought up some new role for drones, even if there are limits to what can be carried. As for UASs performing plant maintenance, “I very much see the day when we could be doing that.” ■

—Thomas W. Overton, JD is a POWER associate editor.