Latest

-

Commentary

Economies of connection

The advent of the Smart Grid will bring a new driver for value creation to the electric power industry: economies of connection. In the future, the Smart Grid may offer our industry improved returns more typical of Internet-based businesses like eBay, Amazon, and Google to replace the diminishing returns typical of traditional “steel in the […]

-

O&M

Focus on O&M (April 2008)

Tag-teamed seawater cleanup; New cooling towers to improve river’s health; Back to school

-

Legal & Regulatory

Regulators should stop playing the greed card

In early February, Western GeoPower (WGP) announced its termination of a 20-year geothermal power purchase agreement (PPA) with Pacific Gas and Electric Co. (PG&E). A WGP press release explains that the company terminated the agreement because a regulatory approval condition had not been obtained within a 180-day time period stipulated in the PPA. WGP’s CEO, […]

-

Nuclear

Super Tuesday, Super Bowl XLII, and the nukes

The nuclear renaissance is likely to slow next year with a new tenant in the White House and many key regulatory positions in flux. Nuclear industry leaders are especially concerned that rules for construction loan guarantees will fall victim to the “wait and see” disease that infects those inside the Beltway every four years. If those rules aren’t in place before this November’s election, the nuclear renaissance may revert to the Dark Ages.

-

Coal

New coal plant technologies will demand more water

Population shifts, growing electricity demand, and greater competition for water resources have heightened interest in the link between energy and water. The U.S. Energy Information Administration projects a 22% increase in U.S. installed generating capacity by 2030. Of the 259 GW of new capacity expected to have come on-line by then, more than 192 GW will be thermoelectric and thus require some water for cooling. Our challenge will become balancing people’s needs for power and for water.

-

Nuclear

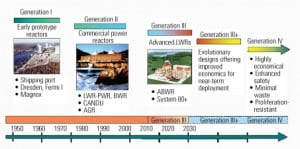

Developing the next generation of reactors

Dozens of intrinsically safe Generation III+ reactors are expected to be deployed in the U.S. in the coming years. Today, scientists already are looking over the horizon to Generation IV reactors that will be capable of producing hydrogen and process heat as well as electricity while generating much less radioactive waste.

-

Instrumentation & Controls

Turbine technology maturity: A shifting paradigm

Selecting the right turbine(s) for a specific power project is a complex process that poses two challenges. One is understanding which field experience cited by suppliers represents proven technology; the other is evaluating whether a turbine upgrade represents an evolutionary change or a revolutionary transformation that warrants further study before deploying it in the field. Here‘s how a leading EPC contractor makes technology-neutral equipment selection decisions on behalf of its customers.

-

Instrumentation & Controls

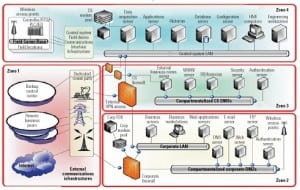

Time to get serious about security

Managing ongoing threats to power plants’ digital, telecommunications, monitoring, control, and automation systems is no longer just a good idea. It’s an essential element of superior plant operations and now a regulatory requirement as well, thanks to new critical infrastructure protection standards recently approved by FERC.

-

Gas

Castejon 2: Ready to reign in Spain

The new, 424-MW Castejon 2 combined-cycle plant designed and built by Alstom was recently given its provisional acceptance certificate. Alstom used its “Plant Integrator” approach to fast-track delivery of a plant just like Castejon 1, which averaged 98% availability during its first three years of operation. That kind of performance is crucial to generators operating in the Spanish merchant power market—or any market.

-

O&M

The aging workforce: Panic is not a strategy

Leaders in the utilities sector talk a lot these days about talent. On one hand, they express concern about facing a shortage of knowledgeable staff as 76 million baby boomers exit the workforce. On the other, they worry about where they’ll find enough qualified people to remain competitive in light of the fierce battle for engineering talent that globalization has created. The antidote to these worries lies in reconfiguring HR practices.