Latest

-

Coal

Top Plant: Brandon Shores Generating Station, Pasadena, Maryland

Constellation Energy Constellation Energy recently completed a series of air quality upgrades on both units at its Brandon Shores Generating Station that included flue gas desulfurization (FGD), baghouse, SO3 control, and mercury reduction by activated carbon injection. The plant’s unique arrangement required long duct runs to the air quality system and a mile-long conveyor for moving barge-delivered limestone to the plant. Treated municipal wastewater was used as wet FGD supply water, and effluent treatment included first-of-its-kind nitrogen removal before discharge to the Chesapeake Bay watershed.

-

Coal

Top Plant: Brunner Island Power Plant, York Haven, York County, Pennsylvania

The 1,456-MW Brunner Island coal-fired plant has implemented advanced environmental improvements in order to be a good neighbor to the residents of south central Pennsylvania. For example, between 2006 and 2010, PPL invested more than $860 million in pollution control upgrades for air, water, and solid waste treatment at the facility.

-

Coal

Top Plant: Dickerson Generating Station, Dickerson, Maryland

Owner/operator: Mirant Corp. Dickerson Generating Station, a 50-year-old facility servicing Maryland and Washington, D.C., was recently upgraded with a flue gas desulfurization system and a unique draft system that allows an electrostatic precipitator and a baghouse to share flue gas cleanup chores on each unit. In addition, state-of-the-art equipment monitoring and diagnostics keep plant reliability high for this baseload unit.

-

Coal

Top Plant: Isogo Thermal Power Station Unit 2, Yokohama, Japan

Unit 2 at J-POWER’s Isogo Thermal Power Station entered commercial service in July 2009. The 600-MW ultrasupercritical unit joins an earlier, similar plant built in 2002. Together, these two new plants replaced 1960s-vintage coal-fired plants and doubled power generation from the small project site. In addition, the new unit improves the plant’s gross thermal efficiency to about 45% while reducing air emissions to those of a gas-fired combined-cycle plant.

-

Coal

Top Plant: Oak Creek Power Plant, Elm Road Units 1 and 2, Milwaukee and Racine Counties, Wisconsin

Adding two 615-MW supercritical pulverized coal units to the 1,135-MW Oak Creek Power Plant is part of We Energies’ ongoing master plan to “Power the Future” of Wisconsin well into the 21st century. The new Elm Road Unit 1 went into service in February, and Unit 2 is expected to start operations during the fourth quarter of 2010. With operations marked by high efficiency and low emissions, these new units will provide large amounts of cleaner energy to the Great Lakes area.

-

Coal

Top Plant: Tolk Station, Earth, Texas

Located in a semi-arid region, this “Texas tough” coal-fired power plant uses a number of smart practices to increase water-use efficiency. For example, a pipeline was constructed to send blowdown water from nearby Plant X for treatment and recycling at the 1,080-MW Tolk Station, making both plants “zero-discharge” facilities. For its environmental stewardship and superior plant operations, the Powder River Coal Users’ Group named Tolk Station its 2010 Plant of the Year.

-

Coal

Map of Coal-Fired Generation in the United States

Courtesy: Platts Data source: POWERmap All rights reserved. No reproduction allowed.

-

O&M

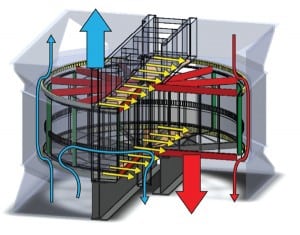

Air Preheater Seal Upgrades Renew Plant Efficiency

The air preheater is a critical, yet often overlooked, component of the boiler combustion air system. Evaluating and optimizing a heater’s performance is difficult given how entwined it is with the entire combustion system and the lack of standardized calculation tools. Reducing leakage by using modern seal technology will improve combustion efficiency, maintain fan performance, and keep your downstream air quality control equipment operating within spec.

-

O&M

Taming Condenser Tube Leaks, Part II

In Part I of this two-part report we examined the various chemical forces at work in condenser tube leaks, the steam plant components placed at risk, and the suite of instrumentation most capable of providing early warning of a leak. Assuming you were able to repair the leak and quickly resume operation, the next step is to identify the damage mechanisms that caused the problem so you can minimize future leaks.

-

O&M

FBC Control Strategies for Burning Biomass

As a boiler fuel, biomass has shown great promise while suffering from a slow development history. One factor limiting its use has been the combustion system. For the most part, conventional grate-fired boilers have been the only option. Today, the most efficient approach to burning biomass to produce electricity and steam is fluidized bed combustion (FBC). Whether you choose FBC or grate, biomass presents unique challenges to control system designers.