In This Issue

-

Nuclear

German Court Questions Legality of Nuclear Tax

A German finance court in September questioned the constitutionality of a controversial tax on fuel used in nuclear power plants, a decision that could influence rulings in various finance courts around the country that are reviewing complaints by nuclear operators regarding the levy.

-

News

Emergency Lighting Solution

BIRNS introduced what it is calling the “world’s most advanced, seismically qualified (per IEEE-344) emergency lighting solution” for nuclear containment: the BIRNS Emergency Light Fixture-LED. The slim-profiled, wall-mounted system provides in excess of 24 hours of continuous, brilliant LED light in the case of power loss in nuclear power facilities and is capable of withstanding […]

-

Nuclear

ITER Gets New Life

The International Thermonuclear Experimental Reactor (ITER) in southern France, the world’s biggest nuclear fusion research project, is seeing a revival. After a budget shortfall last year and cost projections that continue to escalate, in September, the project got the European Parliament’s (EP’s) backing for an autonomous budget that seeks to guarantee transparent and reliable financing while limiting cost overruns. Japan also announced that it would increase its budget for ITER by 50% (the current ITER director-general is Japanese). Also in September, scientists announced that after an 18-month shutdown to upgrade the Joint European Torus (JET)—the world’s largest magnetic fusion device—the machine is ready to test materials to be used inside ITER (Figure 5).

-

Nuclear

Combustion Gas Analyzer

Building on the success of the Fluegas 2700 combustion gas analyzer, the new SERVOTOUGH FluegasExact integrates Servomex’s unique Flowcube flow sensor technology to give users even more confidence in their combustion gas measurements. The analyzer features a patented zirconium oxide cell for oxygen measurement and a thick film catalytic sensor for measuring carbon monoxide (CO) […]

-

Business

POWER Digest (November 2011)

Wärtsilä to Provide Rwanda with Engines for Lake Methane Power. Wärtsilä on Sept. 30 said it was awarded a contract by KivuWatt, a subsidiary of the New York–based international power company ContourGlobal, to supply a power plant to the Republic of Rwanda. The turnkey project is of particular significance because the power plant will utilize […]

-

News

Portable Combustion Analyzer

E Instruments International launched the E8500 combustion analyzer, a complete portable tool for EPA compliance-level emissions monitoring and testing. The E8500 is ideal for regulatory and maintenance use in boiler, burner, engine, turbine, furnace, and other combustion applications. The analyzer includes electrochemical sensors for oxygen, carbon monoxide, nitrogen oxides (measuring both low and true values), […]

-

Nuclear

THE BIG PICTURE: Reactors Under Construction

For seven years in a row, the number of new nuclear construction starts increased markedly. Then the accident at Japan’s Fukushima Daiichi plant occurred, prompting shutdowns of existing plants and a rethinking of future plans in many countries. Nevertheless, the International Atomic Energy Agency (IAEA) expects “continuous and significant growth” in the use of nuclear […]

-

Commentary

Hazard Recognition and Control: Improving Safety’s Bottom Line

The power generation industry is a highly competitive one in which players continue to change and the race for profits is a tough one with the challenge of heavy environmental regulations. One of the most overlooked areas for cost savings is safety. Notwithstanding the moral and legal responsibilities that power plant management has for creating a workplace where everyone can work without injury, reducing and eliminating workplace injuries and illnesses is good for business.

-

O&M

Steam Turbine Cleaning Using Chemical Foams

In the May issue, we discussed the importance of either preventing copper plating of the high-pressure (HP) steam turbine rotor or finding a good foam or mechanical removal means of restoring lost efficiency. In that article we noted that “copper deposits typically form on the stationary nozzle block or first-stage stationary blades” and that those deposits usually result in a steam turbine loss of capacity at a rate of about 2 to 3 MW per month. We also stated that the “general rule of thumb is that there is a reduction of about 1 MW of generating capacity for each 1 to 2 pounds of deposit that accumulates on the HP turbine.

-

O&M

Improving Condenser O&M Practices

Losses attributed to condenser tube leaks, fouling, and failures continue to climb, costing the power generation industry an estimated half-billion dollars annually in maintenance costs and loss of production. Investing in an effective condenser maintenance program will reduce those expenses in short order.

-

O&M

Predictive Maintenance That Works

This is the fourth in a series of predictive maintenance (PdM) articles that began in the April “Focus on O&M” with an introduction to PdM as a process whereby maintenance is performed based on the condition of the equipment rather than on a predetermined interval. In the May and July issues, we began exploring specific PdM techniques, such as motor-current signature analysis and oil analysis.

-

News

Combustion Gas Analyzer

Building on the success of the Fluegas 2700 combustion gas analyzer, the new SERVOTOUGH FluegasExact integrates Servomex’s unique Flowcube flow sensor technology to give users even more confidence in their combustion gas measurements. The analyzer features a patented zirconium oxide cell for oxygen measurement and a thick film catalytic sensor for measuring carbon monoxide (CO) […]

-

Legal & Regulatory

The Water-Energy Balancing Act

Water has long been energy production’s silent partner. In the past, we Americans seemed to take it for granted that plentiful water supplies would be available for a variety of energy needs ranging from the operations of coal-fired power plants to natural gas production activities.

-

Nuclear

Top Plants: Four Plants Demonstrate Global Growth of Nuclear Industry

The global nuclear industry is moving forward at a brisk pace, only slightly slowed by the Fukushima Daiichi accident. The International Atomic Energy Agency’s most realistic estimate is that 90 new nuclear plants will enter service by 2030. Ten new nuclear plants went online over the past two years. We profile four of them as POWER’s nuclear Top Plants for 2011.

-

O&M

Optimizing Condenser Tube Selection

Selecting the most economical tube for a new condenser, or the retrofit of an existing one, is much more complex than mere price shopping. Each material has unique performance characteristics that affect the operating economics of the entire plant. A case study illustrates the importance of carefully choosing the tube material that is right for your plant.

-

O&M

Condenser Tube Failure Mechanisms

The operating environment within a condenser is extremely harsh, and in spite of the designer’s best intentions, sometimes tubes made of the best materials fail. The most important tube failure mechanisms typically result from different forms of corrosion and erosion. When it’s time to select new condenser tube material, you’ll need to consider the projected operating environment and failure mechanisms that material will be subjected to.

-

O&M

Condenser Retubing

Once the condenser tubes are designed, selected, and purchased, the final step in a retubing project is to remove the old tubes and install the new ones. The success of this project is very dependent upon attending to quality control, following proper procedures, using the right tools, and having a highly skilled workforce.

-

Gas

Nordic Nations Provide Clean Energy Leadership

In the past few years, nuclear concerns, rising oil prices, and a growing understanding of our environmental impact has given energy issues a higher profile worldwide. In this report on the Continental Nordic countries, we look at the efforts being made in much of the Nordic region to secure a sustainable energy supply for the future and at the extent to which the innovative solutions of these countries can be exported around the globe.

-

News

It’s More Than a Process

The Office of the Inspector General (OIG) of the U.S. Environmental Protection Agency (EPA) recently concluded that the agency failed to follow prescribed policies in its peer review of the technical support document that provided the justification for its 2009 “endangerment finding” on greenhouse gases. The OIG report is timely, but in an unexpected way.

The Office of the Inspector General (OIG) of the U.S. Environmental Protection Agency (EPA) recently concluded that the agency failed to follow prescribed policies in its peer review of the technical support document that provided the justification for its 2009 “endangerment finding” on greenhouse gases. The OIG report is timely, but in an unexpected way.

-

Nuclear

The U.S. Spent Nuclear Fuel Policy, Part 2: Playing Hardball

Ongoing investigations into cancellation of the Yucca Mountain project have revealed an astonishing number of irregularities by agencies responsible for the project. Those investigations have exposed a broken system that failed to properly manage the project and that surrendered to political pressure. Worse still, the draft report of President Obama’s Blue Ribbon Commission on America’s Nuclear Future gave the industry little reason to hope that there would ever be a long-term nuclear waste fuel repository.

-

Gas

Blackout Leaves Southwest in the Dark

A large swath of Southern California, parts of Arizona, and Northern Baja Mexico was blacked out on Sept. 8—leaving seven million people in the dark—after an Arizona utility worker fixing faulty equipment near Yuma reportedly tripped the 500-kV North Gila–Imperial Valley transmission line, causing the outage. The blackout prompted two units at the San Onofre Nuclear Generating Station to go offline, stranded many people in elevators and trains, shut down airports, cut air conditioning on a day well above 90F, and caused damages of $97 million to $118 million, according to early estimates from the National University System’s Institute for Policy Research.

-

Nuclear

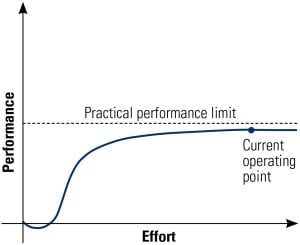

Crossing the Digital Divide

One of the great successes of the power generation industry over the past two decades has been the significant increase in nuclear plant reliability and other performance standards. However, there is reason to be concerned that the design, operation, and maintenance practices used by the current fleet of plants do not leverage all the possible advantages from a digital controls upgrade. Perhaps past success is the biggest barrier to future success.

-

Wind

AMSC Former Employee Convicted in Sinovel Intellectual Property Case

An intellectual property battle between Massachusetts-based American Superconductor Corp. (AMSC) and China’s giant wind turbine maker Sinovel in late September culminated with an Austrian court conviction of a former AMSC employee, who was arrested in Austria and who pled guilty to corporate espionage charges. The court charged Dejan Karabasevic, a 38-year-old Serbian engineer, with stealing AMSC’s software, modifying it, and secretly selling it to Sinovel.

-

Nuclear

Browns Ferry Unit 1 Restart: World-Class ALARA Performance

TVA completed the $1.9 billion restart of the 1,100-MW Browns Ferry Unit 1 in 2007. That restart project provided the opportunity to incorporate state-of-the-art materials and radiation-reduction techniques to ensure that Unit 1 would be an industry-leading low-ALARA-exposure plant when it returned to service. The reductions achieved were significant.

-

Nuclear

Siemens Joins Trend to Quit Nuclear

The number of companies pulling out of the nuclear business continues to grow. Just weeks after Louisiana-based engineering firm The Shaw Group announced it would sell its 20% stake in the nuclear company Westinghouse back to partner Toshiba, German engineering conglomerate Siemens said that, prompted by the German government’s decision to phase out nuclear power by 2022, it would quit the nuclear business.

-

Gas

Global Gas Glut: An Update

In our September article about the global profusion of natural gas, we based a portion of our discussion on the latest, vastly increased natural gas reserve estimates reported by the U.S. Energy Information Administration (EIA). Since our article was published, the EIA has adjusted its estimates downward. We want you to be aware of those lower recoverable reserve estimates. We also want you to know that the conclusions reached in that article do not change with the new estimates of natural gas reserves.