In This Issue

-

Water

Mine Drainage: An Alternative Source of Water

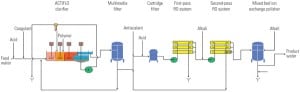

Although mining practices often vary greatly according to the material produced and the value of the deposit, one common denominator is that mining of materials containing sulfide minerals creates acid mine drainage (AMD). AMD is one of the mining industry’s major environmental challenges.

-

Solar

Feed-in-Tariffs Around the World

Feed-in-tariffs (FITs)—above-retail rates paid for renewable power that producers "feed" into the grid—are gaining momentum all over the world as a means of driving project growth. Here are some of those established and proposed FITs.

-

Gas

Top Plant: Langage Combined Cycle Power Plant, Plymouth, Devon, UK

The UK grid, focused on adding valuable renewable generation, will rely on natural gas–fired generation for many years to come. One of the most recent additions is the Langage Power Plant, designed for quick response and low load “parking” at night while remaining below air emissions limits. With an extraordinary architectural design that blends into the natural surroundings, Langage is now a local landmark.

-

Gas

Top Plant: Panoche Energy Center, Firebaugh, California

The Panoche Energy Center is a 400-MW simple-cycle power plant using four of General Electric’s GE LMS100s with fast-start capability. Dispatched by Pacific Gas & Electric to meet regional power and grid stabilization needs, the project entered commercial service two months earlier than planned. Panoche is the largest LMS100 peaking facility in the U.S.

-

Gas

Top Plant: Ras Laffan Power and Water Plant, Ras Laffan Industrial City, Qatar

At the Ras Laffan Power Co. facility, the 756-MW net combined-cycle plant and the integrated 40 million gallons per day desalination plant are working in tandem to provide abundant, reliable electricity and desalinated water to residents of the State of Qatar, the most prosperous nation in the Middle East.

-

Solar

What Utility Executives Think About the Smart Grid

This summary of results from a recent Platts/Capgemini survey of North American utility executives looks at what respondents had to say about all things related to the smart grid. Nearly half of respondents’ utilities have a smart grid strategy in place, while the other half said their utility has one in development.

-

Gas

Top Plant: Sloe Centrale Power Plant, Vlissingen-Oost, Zeeland Province, Netherlands

There’s nothing slow about the fast-track operations at the new 870-MW Sloe Centrale Power Plant. The combined-cycle plant is designed for 250 starts per year and is capable of supplying power to the grid within a mere 30 to 40 minutes. In addition to its impressive rapid load response, the gas-fired plant produces low CO2 and NOx emissions by using the latest technology. It also attains an efficiency of 59%.

-

News

Cap and Trade Is Dead

Cap and trade officially died on July 22 when Senate Majority Leader Harry Reid announced at a news conference that the Democratic Caucus was unable to reach a consensus on any form of energy bill, even a recent short-lived version that proposed reducing carbon emissions from only the utility sector. I predict that carbon cap and trade is now dead for at least a decade, maybe longer.

-

Gas

Top Plant: Timelkam Power Plant Vöcklabruck District, Upper Austria, Austria

Now that the 412-MW Timelkam Power Plant has replaced a 47-year-old coal-fired power plant located in the Vöcklabruck District, northern Austrians can bid auf wiedersehen (goodbye) to high levels of air pollution. Compared to its predecessor, the new gas-fired combined-cycle plant has dramatically cut CO2 and NOx emissions and produces seven times more energy.

-

Legal & Regulatory

Coal Ash Regulation: Playing the Name Game

What’s in a name? Would coal ash labeled as “special” hazardous waste be as easily recycled as that labeled nonhazardous waste?

-

Gas

Top Plant: West County Energy Center, Palm Beach County, Florida

The 3,600-MW West County Energy Center, with two recently commissioned power blocks and a third just entering start-up, is the first “greenfield” combined-cycle plant constructed by FPL since the 1970s. Thanks to FPL’s long history with repowering projects, the project team commissioned Unit 2 seven months early, with no operator errors during start-up. At just over $600/kW, the cost of the plant was a bargain.

-

Commentary

The Hidden Agendas Behind Citizen Suits

The enforcement mechanisms of the environmental statutes in the 1960s were both cumbersome and ineffective.

-

Gas

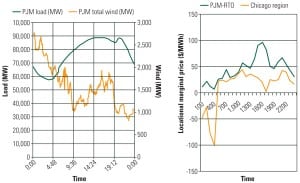

Flexible Turbine Operation Is Vital for a Robust Grid

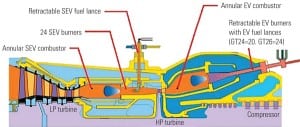

Renewable electricity generation has many environmental advantages, but adding large amounts of far-flung renewable resources to a grid requires increased operating flexibility from dispatchable generators when the wind doesn’t blow or the sun doesn’t shine. One promising option: A combined-cycle plant based on Alstom’s GT24/GT26 combustion turbine can be “parked” at approximately 20% plant load while producing emissions comparable to those during baseload operation—with little loss in thermal efficiency. When demand returns, the combined cycle can return to baseload within minutes.

-

Business

China Completes Ultra-High-Voltage Transmission Superhighway

The State Grid Corp. of China (SGCC) in July put into operation the world’s first ultra-high-voltage direct current (UHVDC) superhighway when it commissioned the Xiangjiaba-Shanghai link. The ±800 kV project, completed in 30 months—a year ahead of schedule—has the capacity to transmit up to 7,200 MW from the Xiangjiaba hydropower plant in southwest China to Shanghai, the country’s leading industrial and commercial center, about 2,000 kilometers (km) away.

-

O&M

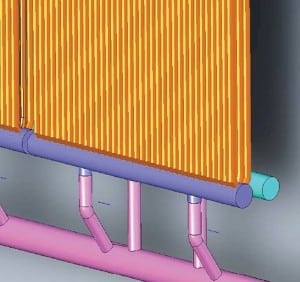

Taming Condenser Tube Leaks, Part I

Summer peaks are still with us, and every unit on your system must be prepared to operate at a moment’s notice. Spot power prices are so high that you expect phone calls asking for a few more megawatts from your units. Then your plant chemistry lab calls to report a condenser tube leak. Your options are few: Shut down immediately and get charged with a forced outage, ignore the leak and keeping running until fall, or schedule a maintenance outage next weekend and hope the leak can be found and fixed. In Part I, we examine what you need to know in order to make an informed decision. In Part II, we’ll explore the actual damage mechanisms.

-

Coal

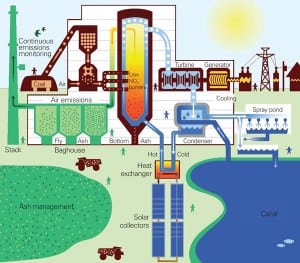

Xcel Energy Fires Up Solar/Coal Hybrid Demonstration

At the end of June, Xcel Energy fired up a demonstration project that integrates a 4-MW parabolic trough solar technology with an existing 44-MW coal-fired power plant.

-

Solar

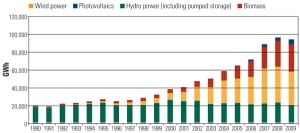

The Feed-in Tariff Factor

Most countries are trying to increase the percentage of their electricity supply that comes from renewable sources. But because capital costs for renewable generation still, in most cases, are higher per kilowatt-hour than for fossil-fueled power, governments are looking at all options for encouraging the development of greater renewable capacity. Feed-in tariffs (FITs) are one policy tool that has been used, most notably in Europe. Now North America is testing FITs as well.

-

Wind

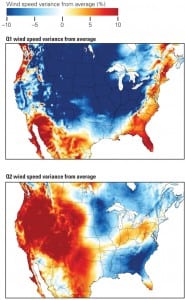

U.S. Wind Speeds Bluster on Climate Phenomena

Renewable energy information services provider 3TIER in July confirmed with its publication of wind performance maps what U.S. wind developers with poor generation numbers had been suggesting earlier this year: A long-lasting El Niño event paired with a North Atlantic Oscillation event caused wind speeds to slump abnormally from the fall of 2009 through spring 2010.

-

Solar

Bulk Storage Could Optimize Renewable Energy

A defining challenge for the U.S. electricity industry is to economically integrate renewable energy facilities into grid operations without sacrificing reliability. Bulk energy storage options are commercially proven technologies that enable that integration most expediently. Existing and emerging national and state policy frameworks are supporting their application in projects under development throughout the country.

-

Solar

Solar Capacity Heats Up Worldwide

Spain in July inaugurated another major concentrated solar power (CSP) power station. The 50-MW La Florida parabolic solar trough plant in Alvarado Badajoz (in the west of the country), increases Spain’s solar nameplate capacity to 432 MW—beating out the U.S., which produces 422 MW from solar installations.

-

Gas

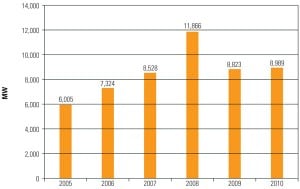

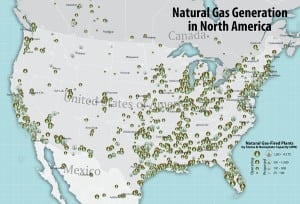

U.S. Gas-Fired Power Development: Last Man Standing

In 2010, U.S. wind power development has slowed, coal-fired power development remained stalled, and the much-awaited renaissance of nuclear power took a few tentative steps forward. That left natural gas power development as the last man standing.

-

Hydro

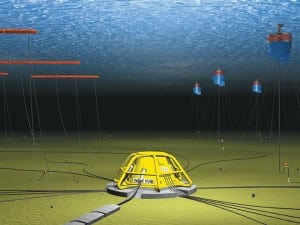

UK Installs Hub to Test Wave Energy Projects

A £42 million marine power infrastructure project that will function as an “electrical socket” in waters 50 meters (m) deep and nearly 16 kilometers (km) off the coast of Cornwall in South West England set sail toward its proposed location this July.

-

News

Ultra-Low-NOx Burner

Hamworthy Peabody Combustion introduced the ECOjet ultra-low-NOx burner. Offering ultra-low burner nitrogen oxide capacities (<30 parts per million) with little or no flue gas recirculation, the burner can be used with a full range of gaseous fuels and with package, industrial, and utility boilers, including single and multi-burner wall-fired, turbo, and other boiler types. Ignition […]

-

Gas

The World’s First Two-Stage Turbocharged Gas Engine

GE launched what it is calling the world’s first two-stage turbocharged gas engine this June.

-

News

Innovative Fire Extinguisher Mount

Poly Performance’s newly launched Quick Release Fire Extinguisher Mount offers an innovative way to safely mount a fire extinguisher to any flat or round surface. The mount can be secured with either bolts or hose clamps. Configurable for any size fire extinguisher, the mount offers split-second removal to maximize emergency preparedness. Poly Performance manufactures the […]

-

Business

POWER Digest (September 2010)

MHI, Foster Wheeler to Support FEED for UK CCS Project. A consortium of Mitsubishi Heavy Industries (MHI) and Foster Wheeler Energy Ltd. on August 5 announced that it had received an order from E.ON UK to support the front-end engineering design (FEED) for a post-combustion carbon dioxide (CO2) capture plant proposed as part of E.ON’s […]

-

News

All-in-One Gas Detection System

Industrial health and safety equipment manufacturer Sensidyne released the SensAlarm Plus, an all-in-one gas detection system for monitoring oxygen, toxic, and combustible gases. The system functions as a single transmitter that offers “Test-on-Demand” and “Predictive Sensor Failure” features, in addition to accepting oxygen, electrochemical, catalytic bead, or infrared sensors. The system provides a large LED […]

-

O&M

Ten Years of Experience with FAC in HRSGs

We first reported on combined-cycle plant reliability concerns due to erosive wear and flow accelerated corrosion (FAC) in heat-recovery steam generator (HRSG) pressure parts at the 1999 EPRI Maintenance Conference. More than 10 years later, these damage mechanisms remain significant contributors to forced outages, pressure part repairs, and major component replacement.

-

Gas

Industry Trends: Map of Natural Gas Generation in North America

Courtesy: Platts Data source: POWERmap All rights reserved. No reproduction allowed.