Plant Design

-

Coal

The Future of Coal Power: Development and Siting Obstacles for New Coal Plants

In recent years, Sargent & Lundy has evaluated many potential sites for new coal-fueled generation. Some of the sites studied were lands adjacent to existing power plants (brownfield sites); others were undeveloped greenfield sites. The numerous technical, environmental, economic, and regulatory issues that bear on power plant siting generally apply to both brownfield and greenfield […]

-

Coal

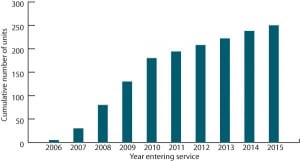

The Coal Patrol: Growth in PRB Coal Use Will Be Fueled by New Projects

Production from Wyoming Powder River Basin (PRB) coal mines ended last year with a increase of only about 1.1%, reflecting a record 451.3 million tons, according to the Department of Energy’s Energy Information Administration. Production of PRB coal spiked with a record 10% growth in 2006 following two derailments on the PRB’s main triple-track line […]

-

Coal

FutureGen: FutureGen Finds a Home But Can’t Pay the Mortgage

The FutureGen Industrial Alliance Inc. selected Mattoon, Ill., as the site of the $1.8 billion FutureGen project just before Christmas, but the plant may never move off the drawing board.. FutureGen, the proposed prototype of a near-zero-emissions coal plant, is to demonstrate advanced technologies for coal gasification, electricity production, emissions control, CO 2 capture and […]

-

Coal

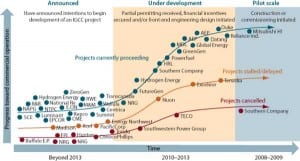

IGCC: IGCC’s Future Hinges on a Workable Carbon Framework

Integrated gasification combined-cycle (IGCC) technology, a process of gasifying coal that allows the capture of carbon dioxide emissions, has tremendous potential for meeting future baseload generation demand. Though it is one of the leading alternatives for producing clean power from coal, IGCC faces a precarious future due to rising capital costs and regulatory uncertainty. We’re […]

-

Coal

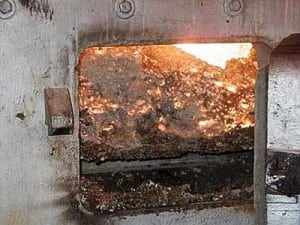

Advanced Combustion: Cofiring Coal and Biomass or Non-Recyclable Waste

Burning biomass or nonrecyclable commercial, municipal, or industrial waste along with coal represents one of the nearest-term and lowest-cost options for reducing carbon dioxide (CO 2) emissions from existing utility power plants. At more than 150 plants worldwide, doing so has produced lower CO 2 emissions than burning coal alone. Indeed, with the number of […]

-

Coal

Coal Plant O&M: Retrofit Flyash-Handling System Pays Dividends

Like many older coal-fired plants, Westar Energy’s Jeffrey Energy Center (JEC) was built with traditional, pneumatic flyash-handling and removal systems. Such systems collect flyash in hoppers attached to the bottom of a unit’s electrostatic precipitator (ESP) and/or baghouse. Periodically, the hoppers are emptied into tanks and the flyash is conveyed away for disposal or beneficiation. […]

-

Coal

Safety: Detecting Fires on PRB Coal Conveyors

All conveyor systems are at risk of fire caused by the ignition of transported materials or equipment failure. But the propensity of Powder River Basin (PRB) coal to self-ignite introduces an exceptional hazard requiring special fire prevention and automatic detection and suppression efforts. To that end, this article discusses the technologies of linear heat detection […]

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

O&M

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]